Process for preparing NaY molecular sieve by using synthetic mother liquor

A technology for synthesizing mother liquor and molecular sieves, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve the problems of slow filtration rate, reduce waste liquid discharge and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

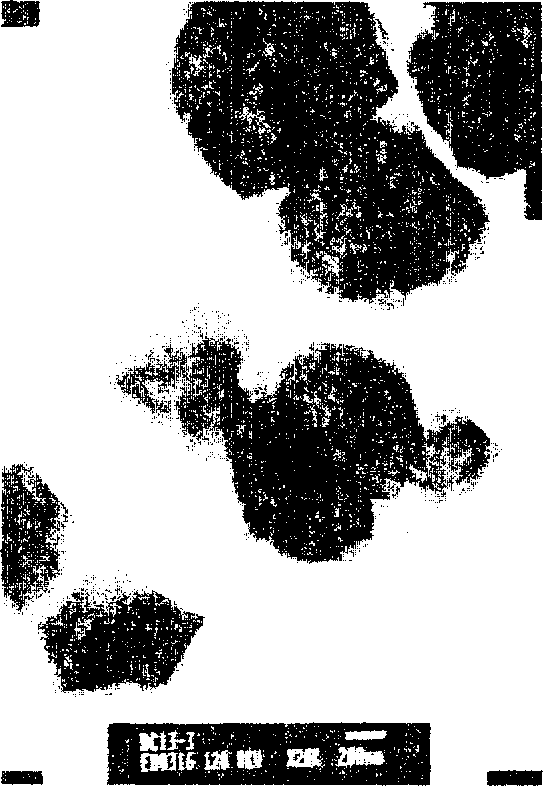

Image

Examples

Embodiment 1

[0040] This example is the preparation of the directing agent.

[0041] Get water glass 126ml (specific gravity 1.278kg / L, SiO 2 content 287 g / L, modulus 3.3) into a beaker, slowly add 105ml of sodium metaaluminate solution (Al 2 o 3 Content 38.7 g / L, Na 2 O content 291 g / L, specific gravity 1233 g / L), mix uniformly at room temperature, age at 35°C for 6 hours, and make a molar ratio of 16.85Na 2 O:Al 2 o 3 : 15.1SiO2 2 : 320.8H 2 O's directing agent.

Embodiment 2

[0043] This embodiment is the preparation of silica-alumina glue.

[0044] Get industrial NaY mother liquor 1500ml (Qilu Catalyst Factory, specific gravity 1.110, SiO 2 Content 53.3 g / L, Na 2 O content 26.6 grams / liter), while stirring mother liquor with the rotating speed of 700r / min, slowly add aluminum sulfate solution 154ml (Al 2 o 3 Content 98 g / L, specific gravity 1.291), forming silica-alumina glue slurry. After stirring evenly, put the silica-alumina glue slurry into a water bath at 95°C for heating and aging for 2 hours. Take out the aged silica-alumina glue slurry and filter it on a φ200 Buchner funnel with a vacuum of 0.05Mpa. Obtain silica-alumina gel filter cake.

Embodiment 3

[0046] This example is the preparation of NaY molecular sieves with large grains and large particles.

[0047] Pre-crystallization step: get water glass 210ml (specific gravity 1.278kg / L, SiO 2 Content 287 grams per liter, modulus 3.3) put into 2L enamel cup, add the silica-alumina gel filter cake 1087g in the embodiment 2 when stirring water glass, the directing agent 88ml in the embodiment 1, aluminum sulfate solution 33ml (Al 2 o 3 Content 98 g / L, specific gravity 1.291), sodium metaaluminate solution 77ml (Al 2 o 3 Content 102 g / L, Na 2 O content is 159 g / L, specific gravity is 1.240), mixed evenly, and pre-crystallized at 95° C. for 2 hours. Among them, the SiO provided by the silica-alumina gel filter cake 2 SiO in the precrystallization reaction mixture 2 The mass percentage is 55%, the Al in the directing agent 2 o 3 accounted for the total Al in the precrystallization reaction mixture 2 o 3 5% of the amount.

[0048] Crystallization step: take out 800g of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com