Conic spiral sprayer for desulfurizing and dusting and its making methd and mould

A technology for desulfurization, dust removal, and spiral nozzles is applied in separation methods, chemical instruments and methods, and injection devices. Excellent fogging performance and good fogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

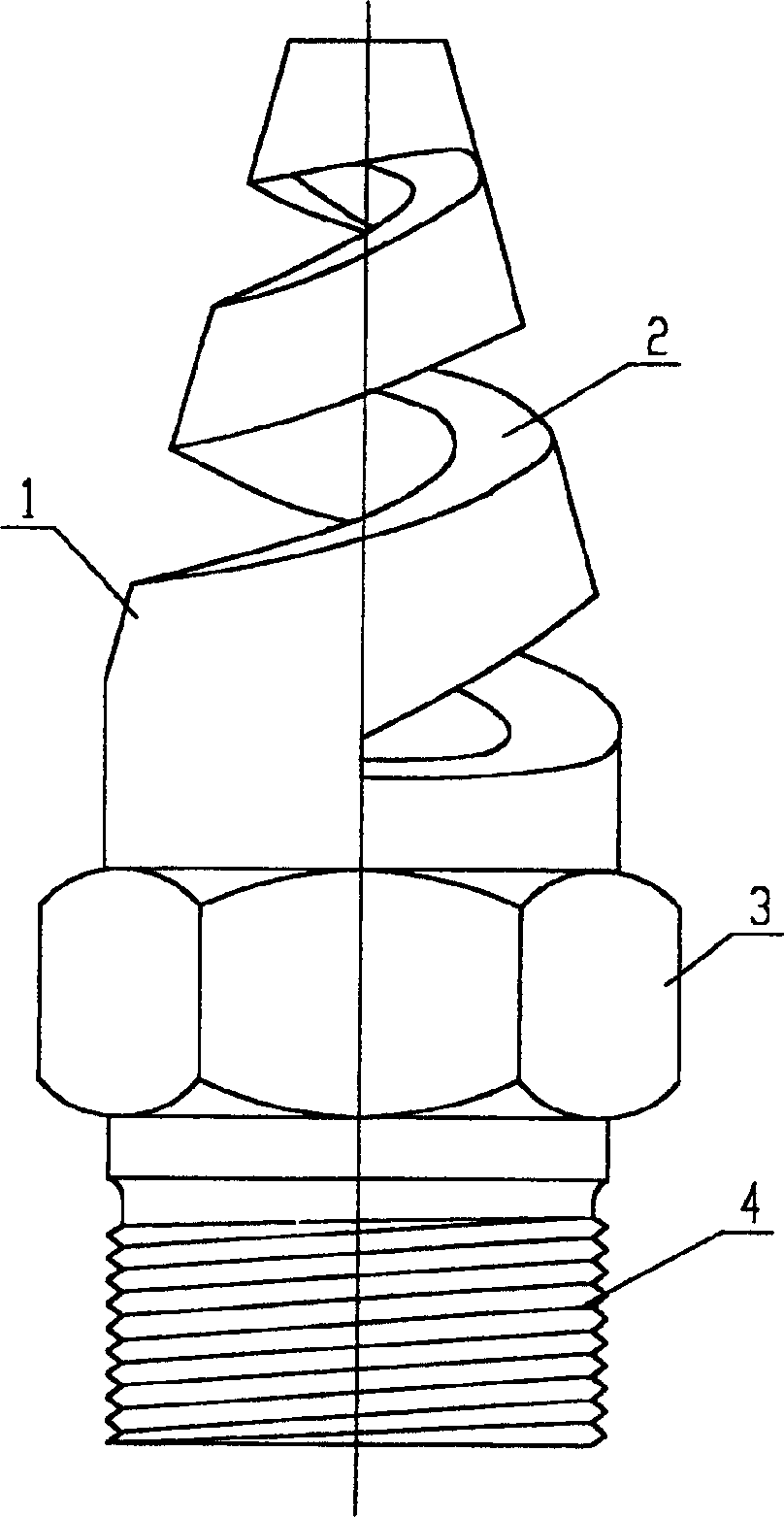

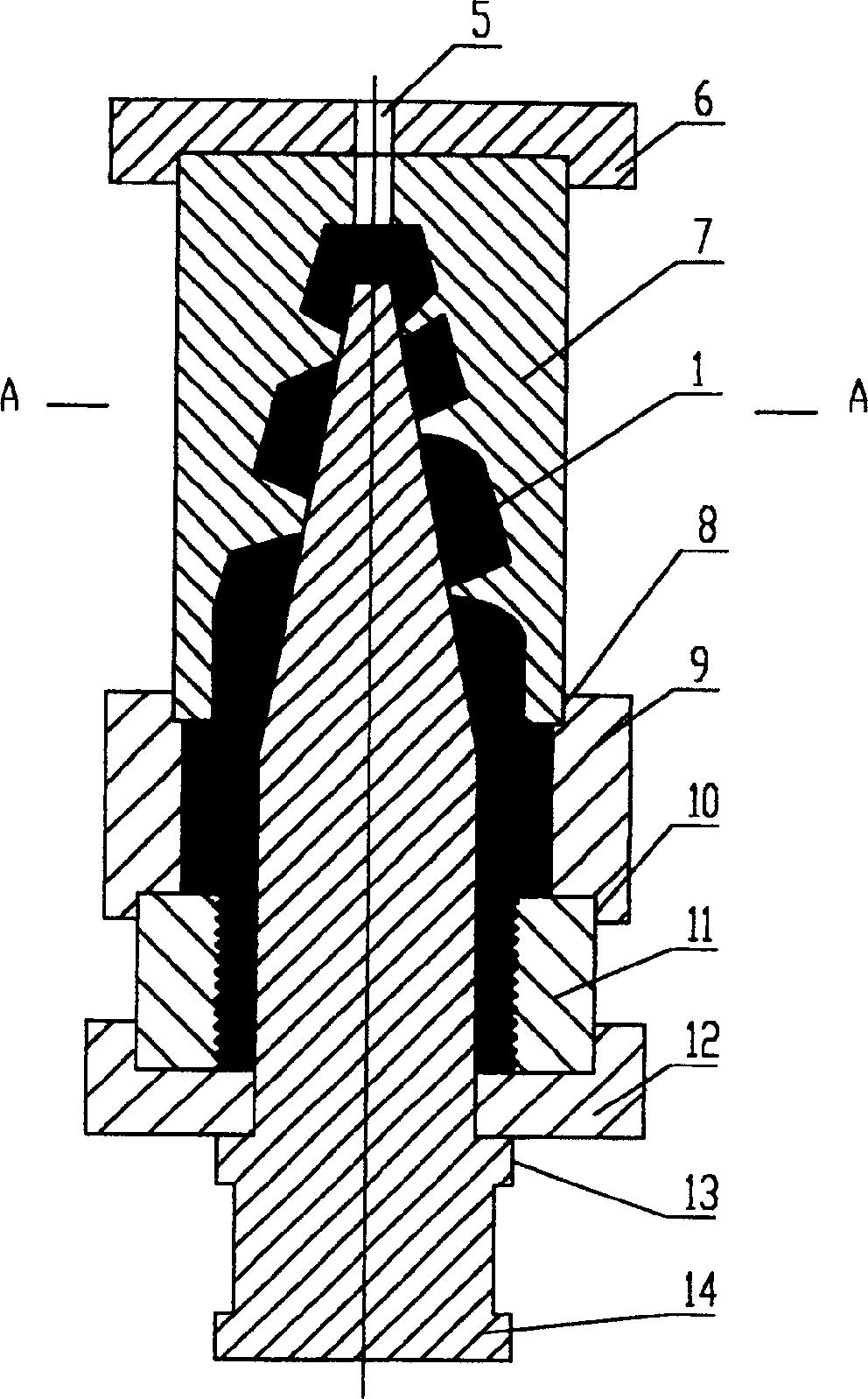

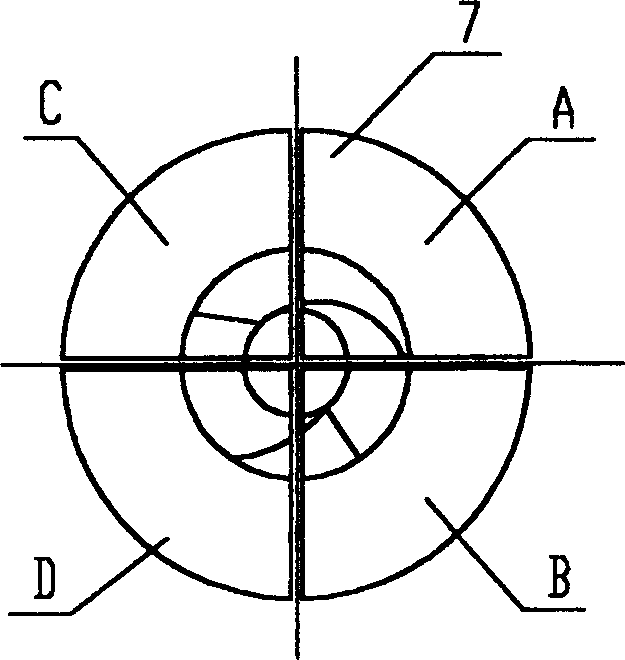

[0015] Embodiment 1: See the accompanying drawings, the conical spiral nozzle 1 is formed by grouting and sintering of alumina ceramics, the front section is composed of spiral spray grooves 2 rotating alternately to form a conical structure, and the rear part of the nozzle has a tightening nut 3 and a connecting external thread 4 . The combined disassembly mold of the grouting molding is composed of a tapered mandrel 14 and a combined outer mold with a positioning shoulder 13 integrally matched with the inner hole of the nozzle. Combined external mold (such as figure 2 ) from bottom to top in turn by the lower positioning locking ring cover 12, the thread forming ring 11 with internal threads, the nut forming ring 9 with positioning locking concaves 8, 10 at the upper and lower ends, and the four-lobe combination ( image 3 , 4 ) has a spiral groove forming block 7, and the upper positioning locking ring cover 6 sets are inserted. The upper positioning locking ring cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com