Production method of Mocha tea and special equipment thereof

A production method and technology of fresh tea leaves, which are applied in the field of production of natural steamed green tea edible ultrafine powder matcha, can solve the problems that the powder size and particle size cannot be strictly controlled, the aroma is not high, and the aroma type is unstable, etc. Sustained development, improvement of safety level, and the effect of ensuring food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Tea Garden: Nanjing Zheluoshan Tea Farm, time: May 10, raw material: 4.5 kg single fresh leaf of a clone of improved variety - "Nongkangzao".

[0053] The specific production method and process are as follows:

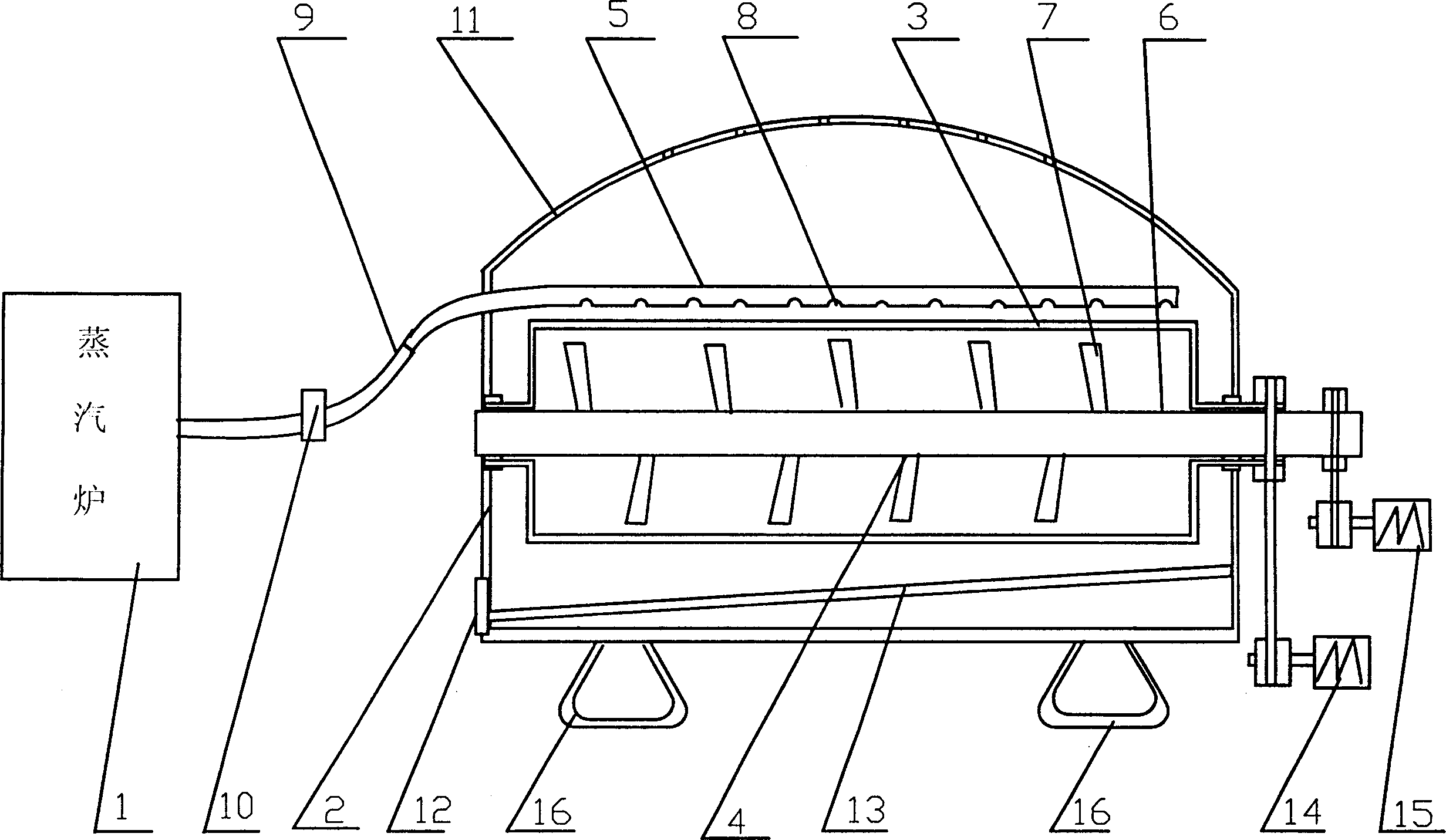

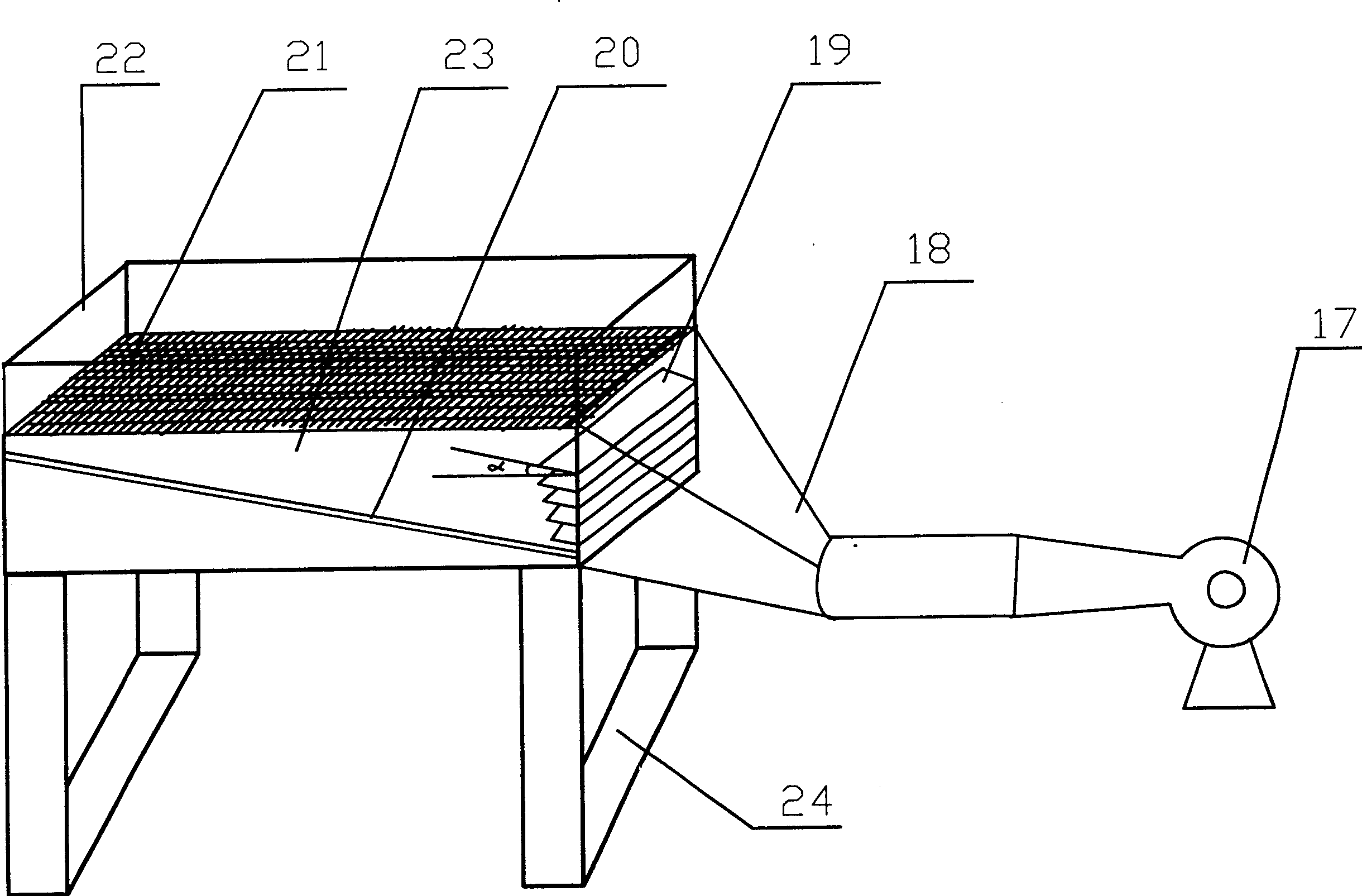

[0054] First cool wind blows fresh leaf 5~10 minutes, then enters the two-speed drum type fixing machine of the present invention (such as figure 1 ) for 45 seconds, and when the steam pressure is 3.5 kg, the steam temperature is about 125°C; then cool with ice water for 15 seconds, and enter the dehydrator (TS15 food dehydrator produced by Guangzhou Panyu Food Machinery Co., Ltd.) for dehydration for 1~ 2 minutes; Adopt air drier of the present invention again (as figure 2 ) with natural wind for air-drying, while gently kneading with hands for 5 minutes, and cool air for 15 minutes.

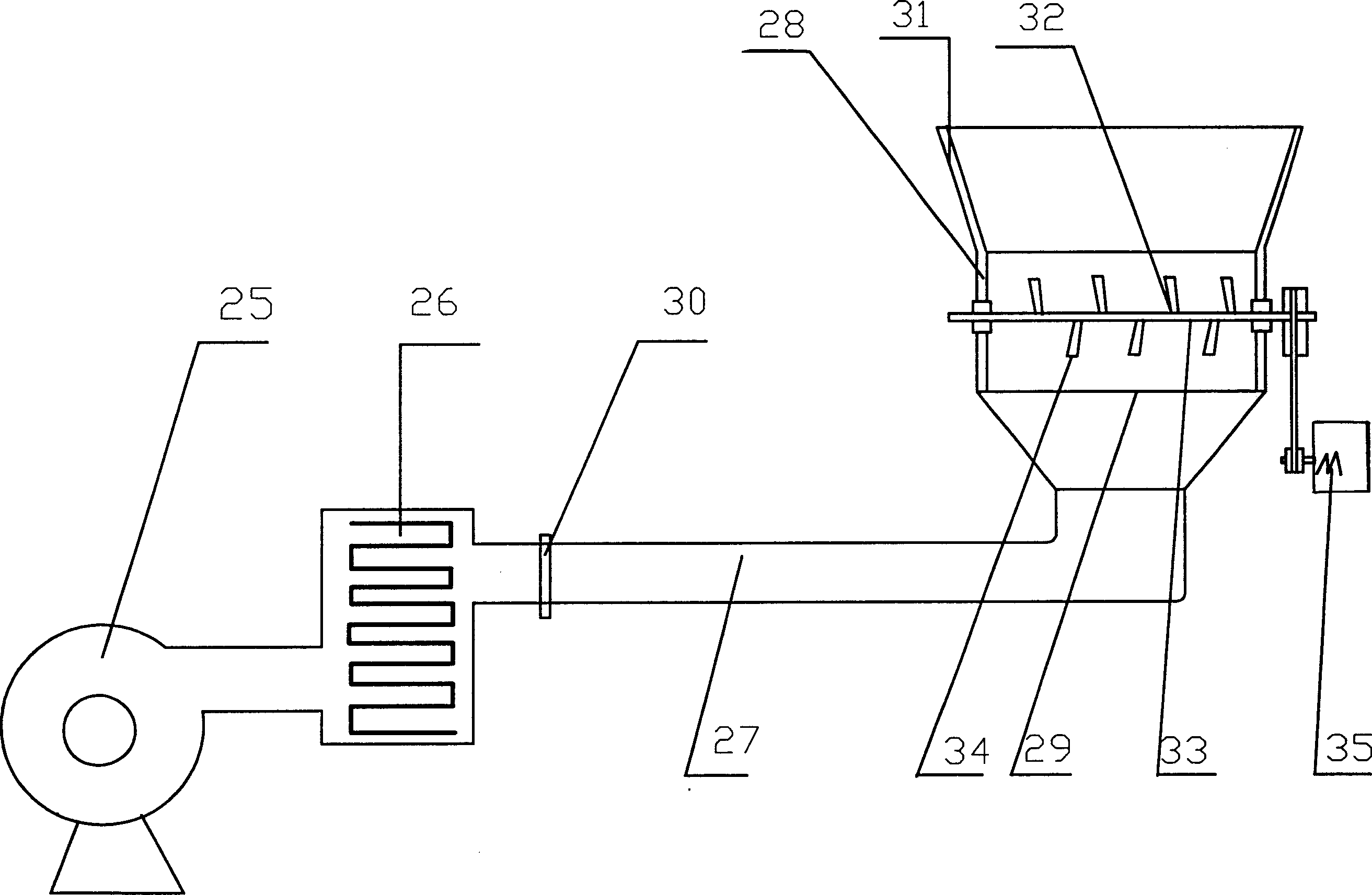

[0055] Adopt fluidized dryer of the present invention (as image 3 ) drying for 13 to 15 minutes, the temperature is controlled at about 95°C, and the moisture content is con...

Embodiment 2

[0059] like figure 1 As shown, the two-speed drum type steam degreening machine of the present invention is the degreening equipment used in the process of producing matcha, and it includes a steam oven 1, a cabinet 2, a drum 3, a rolling rake 4 and a steam pipe 5, and the rolling rake 4 includes a rotating shaft 6 and The blade 7, the roller 3 and the roller rake 4 are all set in the cabinet 2, and the roller shaft is set on the roller rake shaft, and the two realize differential rotation through the transmission mechanism, and the two can be realized by a set of motors and differential transmission mechanism. Transmission, also can realize differential rotation by motor 14, motor 15 among two groups of motors, the rotating speed of cylinder 3 can be 45 rev / mins, and the rotation of roller rake 4 can be 90 revs / mins. The surrounding wall of the drum 3 is a grid or has a number of air hole structures and is provided with a door body; the steam pipe 5 is installed above the dru...

Embodiment 3

[0062] like figure 2 As shown, the air dryer of the present invention is the equipment used for air-drying in the matcha production process. It includes a fan 17, an air guide pipe 18, an air guide plate 19 and a bellows 23. The top surface 21 of the bellows 23 is a grid structure. There is a baffle 22, and the air inlet positioned on the side of the bellows 23 communicates with the blower fan 17 through the air guide pipe 18, and a row of air guide plates 19 are arranged at the air inlet of the bellows 23, and the bottom of the side with the air inlet is opposite to it. A dividing plate 20 compatible with the bellows 23 is connected between the tops of the tops. The wind deflectors 19 located at the air inlet of the air box 23 of the air dryer are parallel to each other and inclined upwards, and the inclination angle α between them and the horizontal plane is preferably 45°.

[0063] Left and right, the bottom surface of air dryer is provided with support frame 24.

[0064...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com