Orthopedic casting articles containing backings having water soluble binders

A water-soluble adhesive and backing technology, applied in bandages, absorbent pads, medical science, etc., can solve the problems of expensive manufacturing costs, and achieve the effects of excellent specific strength, excellent tactility, and low tensile elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

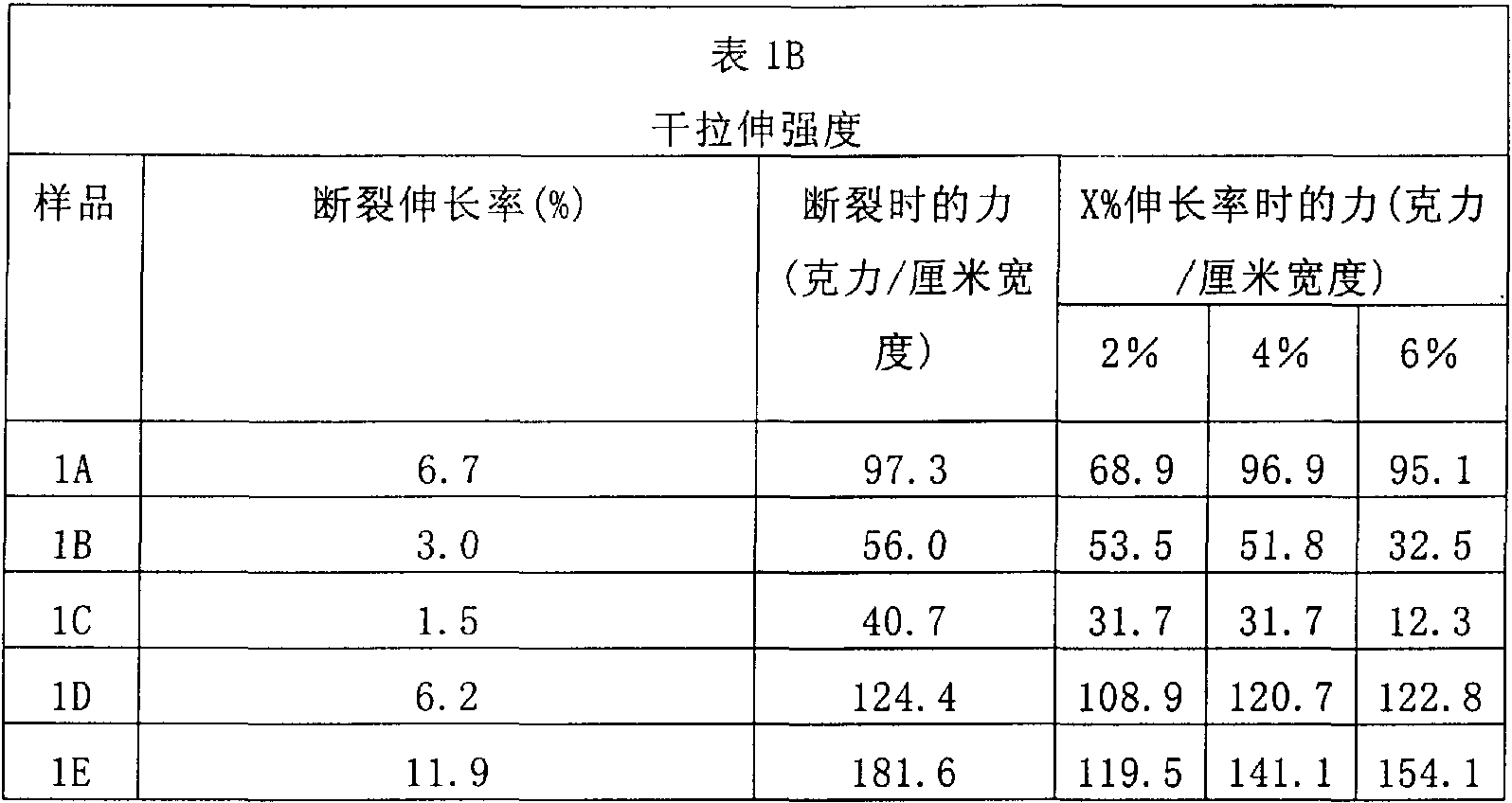

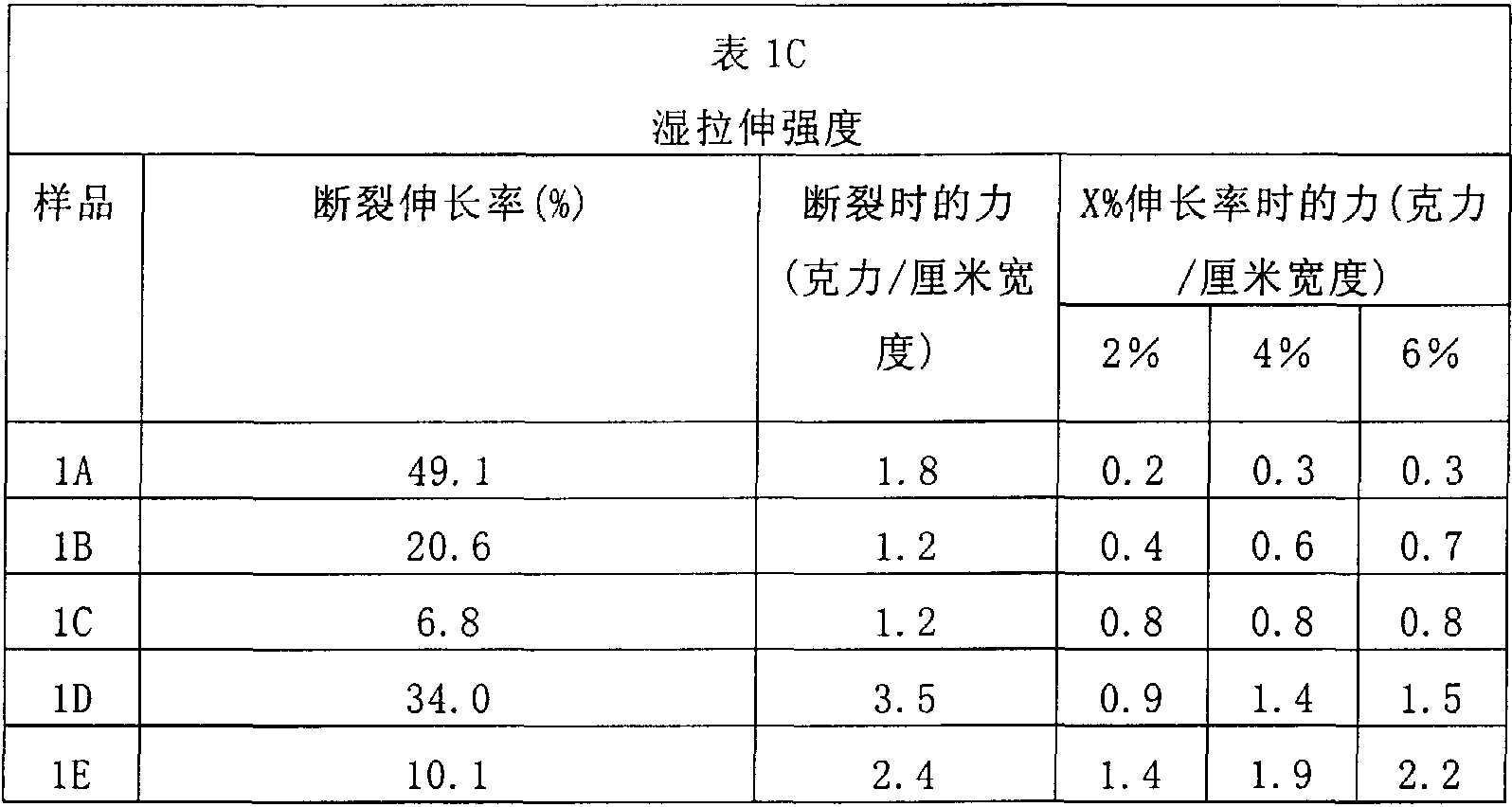

[0042] Carded nonwoven fibrous backing containing water-soluble binder

[0043] A non-oriented double doffer card (Dulmen, Germany, Hergeth Hollingsworth, model WZM / K5-d2-R2) was used to convert different types of fiber materials into various fiber fabric backings of non-woven fabric structure. The fibers were weighed in batches and mixed by hand before being placed in the fiber opening unit located ahead of the Hergeth card. The resulting backing consists of a uniform mat of loose fibers highly oriented in the machine direction with little or no dimensional stability or tensile strength. The fiber materials used, varying in composition, structure, denier, fiber length and basis weight, are listed in Table 1A. High tenacity (HT) straight Minifiber polyester (PET) was passed through a Cadette 500 fiber opener (Laroche Co., France) before being fed into the fiber opening unit.

[0044] Following the carding step, the aqueous binder solution was applied to the nonwoven fabric b...

Embodiment 2

[0050] Microcreped nonwoven and knitted backings with water soluble binder

[0051] Table 2A

[0052]As shown in the results in Tables 2B and 2C, all microcreped nonwoven and knitted fabric backing samples (with and without PVP binder) imparted high dry tensile strength to the material (force at break greater than about 4200 gf / cm width) and high wet tensile strength (force at break greater than about 2900 gf / cm). Additionally, the addition of PVP to the backing samples greatly increased the force required to stretch the fabric, based on the dry tensile strength results. For example, it was measured that the micro-creped SONTARA 8043 backing without PVP adhesive required a force of 17.2 grams per centimeter width when the extensibility was 4%, while that with PVP adhesive increased to 172. 3 gf / cm. Thus, in subsequent processing, such as winding and unwinding of rolls of the backing during resin application, it is expected that the elongation of the fabric backin...

Embodiment 3

[0054] Fabric backing with adhesive and hardenable resin

[0055] (Orthopedic casts and casts)

[0056] table 3

Polyurethane prepolymer resin composition

components

Element

Parts (weight)

Component A

ISONATE 2134L Polyisocyanate (Dow Chemical)

58.91

Benzoyl chloride (stabilizer)

0.05

Subtotal

58.96

Component B

NIAX PPG 725 Polypropylene Oxide Polyol (Pennsylvania,

Newton Square, Arco Chemical Co. ,)

24.99

NIAX PPG 425 Polypropylene Oxide Polyol (Pennsylvania,

Newton Square, Arco Chemical Co. ,)

9.90

DB-100 defoamer (Dow Chemical)

0.18

Arno Antioxidant (Shell Chemical Co.)

0.48

Pluronic F-108(BASF)

3.99

2,2'-Dimorpholinodiethyl ether catalyst (Texas,

Austin, Huntsman Chemical)

1.50

Subtotal

41.04

total

100.0

[0057] A dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com