Method for cracking organic debris reinforced by plasma and plasma furnace

An organic waste and plasma technology, applied in the field of ion pyrolysis, can solve the problems of unsuitable treatment of medical waste, high power consumption, difficult industrialization, etc., and achieve the effect of saving energy and time, low operating cost, and uniform thermal cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

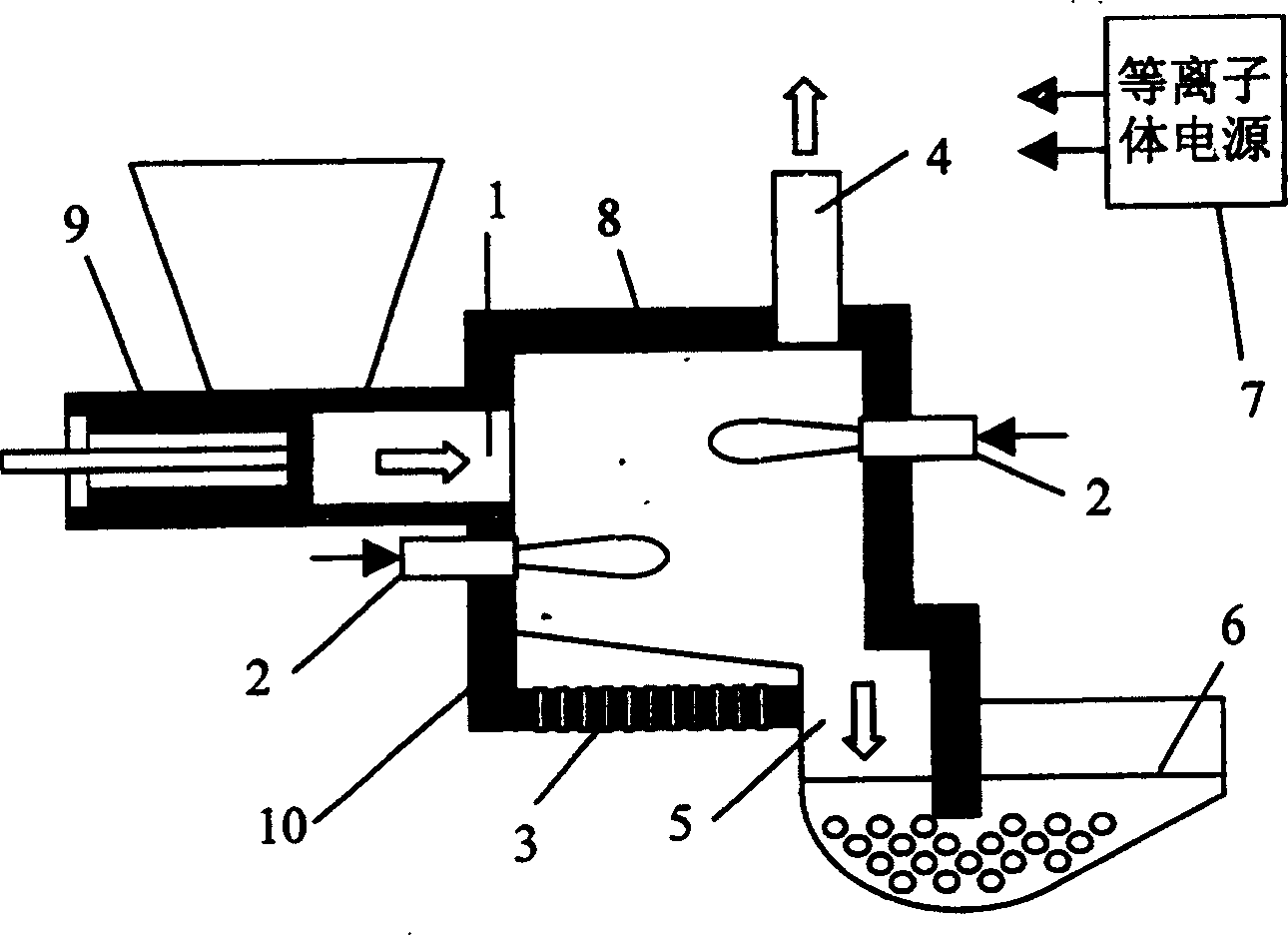

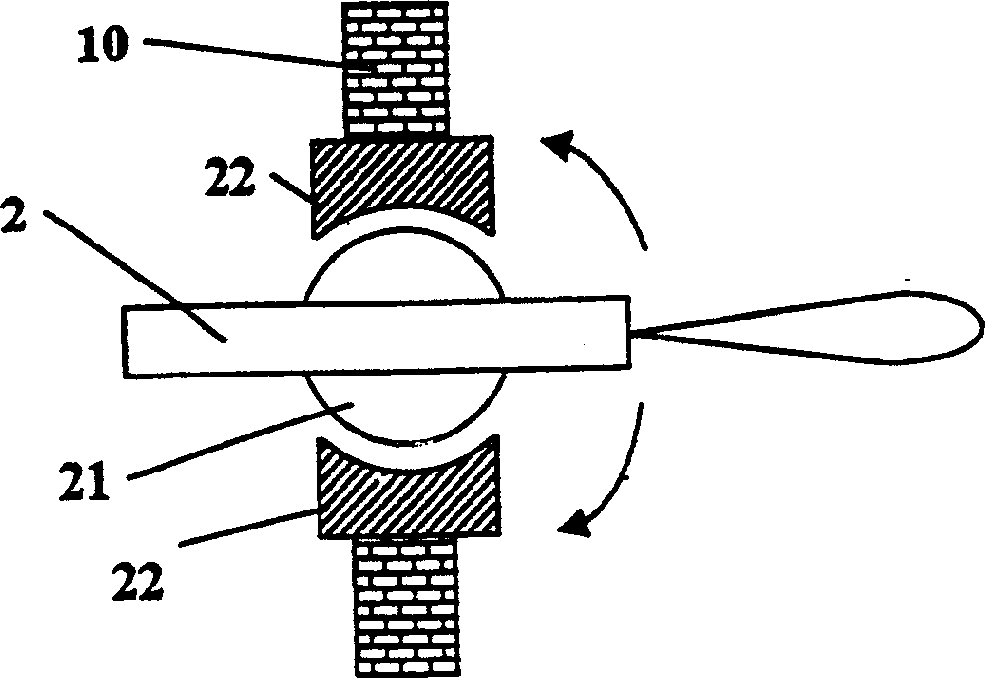

[0055] refer to Figure 1a , is a schematic diagram of a plasma furnace with a rectangular cross-section layout for plasma-enhanced pyrolysis of organic waste. The plasma furnace includes a furnace body 10, the inner side of the furnace body is provided with a furnace lining made of alumina refractory material and a thermal insulation layer, the furnace wall is provided with a feed inlet 1, and two Plasma torch 2, plasma torch is installed on the rotating device, and this rotating device is that plasma torch 2 is installed on a metal water-cooled sphere 21, and water-cooled sphere 21 is positioned on the water-cooled base 22 that two hemispherical metals are made, installs plasma The base 22 of the torch is mounted on the plasma furnace body 10 . The water-cooled sphere 21 can rotate and rotate on the spherical base 22, the sphere's rotation angle ranges from 0 to 40 degrees, and the rotation angle around the center line of the plasma torch is 0 to 20 degrees to match the rot...

Embodiment 2

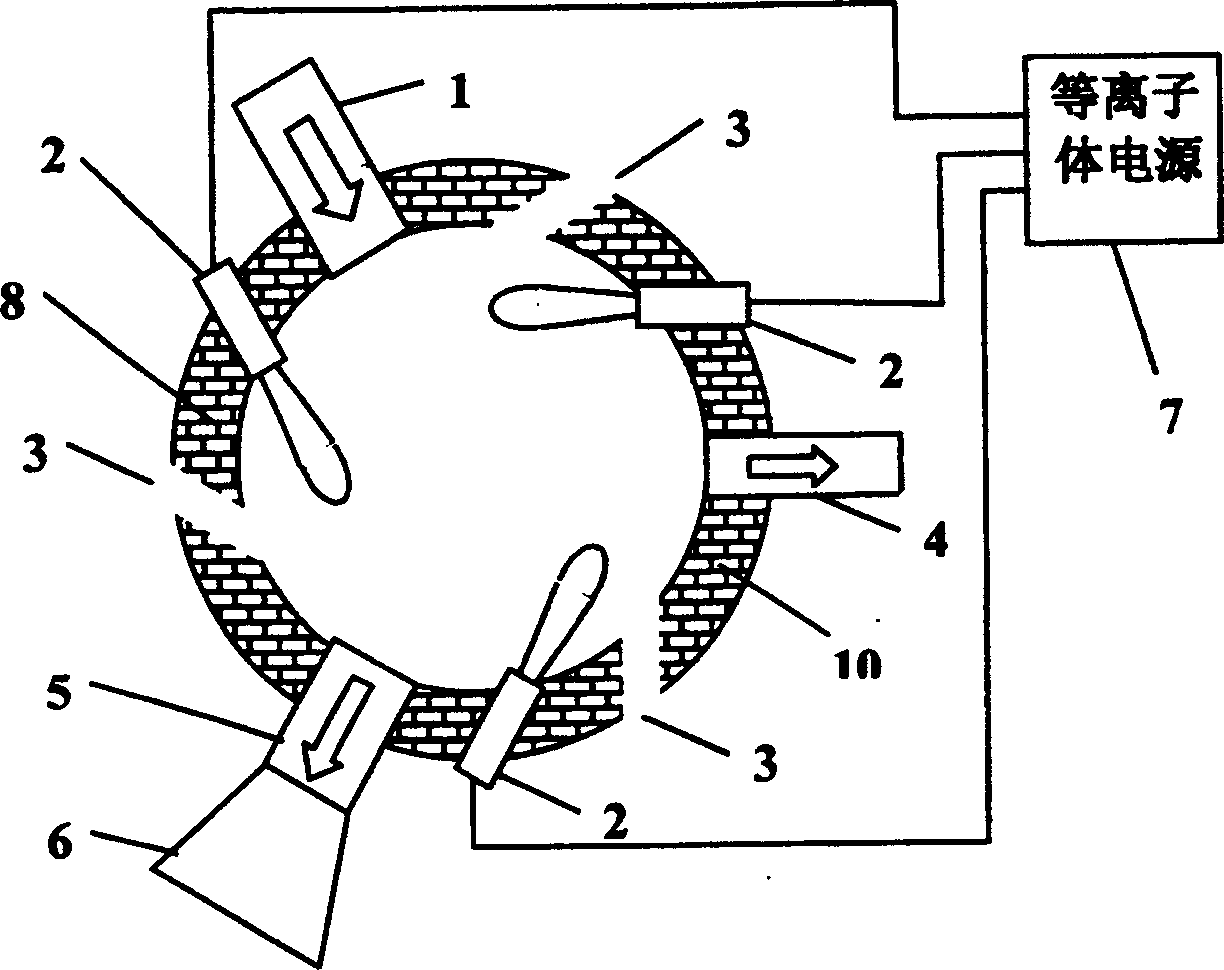

[0057] refer to Figure 1b , is a furnace type with a circular cross-section arrangement for plasma-enhanced cracking of organic waste, the plasma furnace includes a furnace body 10, and the inner side of the furnace wall of the furnace body is provided with a magnesia refractory lining and a thermal insulation layer, A cooling water jacket can be arranged outside the thermal insulation material. The furnace wall is provided with a feed inlet 1, and three plasma torches 2 are installed alternately on the furnace wall, and the three plasma torches are evenly distributed along the furnace circumference, and the axis of the plasma torch is at 80° to the normal direction of the circle. The angle of degree is 60 degrees with the furnace axis; to promote the flow of gas in the furnace and make the temperature distribution in the furnace even; the bottom of the furnace body is provided with a slag outlet 5, and the top of the furnace wall is provided with an exhaust port 4. There ar...

Embodiment 3

[0058] Embodiment 3, using the plasma furnace provided by the present invention to treat medical waste

[0059] The present invention used provides as Figure 1b The plasma furnace shown. The meat containing plastic, cotton yarn and other medical waste and simulated limbs is crushed to a size of 1-50 mm under the condition of being isolated from the outside world and maintaining a slight negative pressure of 0-50 mm water column, and then continuously and stably fed into the plasma through the feeder In the body furnace, the broken organic waste is pyrolyzed in the above-mentioned plasma furnace. The working gas of the plasma torch in the furnace is oxygen, and the total amount of oxygen is controlled so that the amount of oxygen in the furnace is equivalent to the complete combustion of organic waste. 5% of the required theoretical oxygen amount; add oxygen to control the cracking temperature at 1200-1500K, and increase the cracking temperature by increasing the oxygen suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com