Two-stroke internal combustion engine

A technology for two-stroke internal combustion engines and scavenging passages, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of exhaust gas pollution, entry, and engine operation problems, so as to improve fuel economy and scavenging efficiency , the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

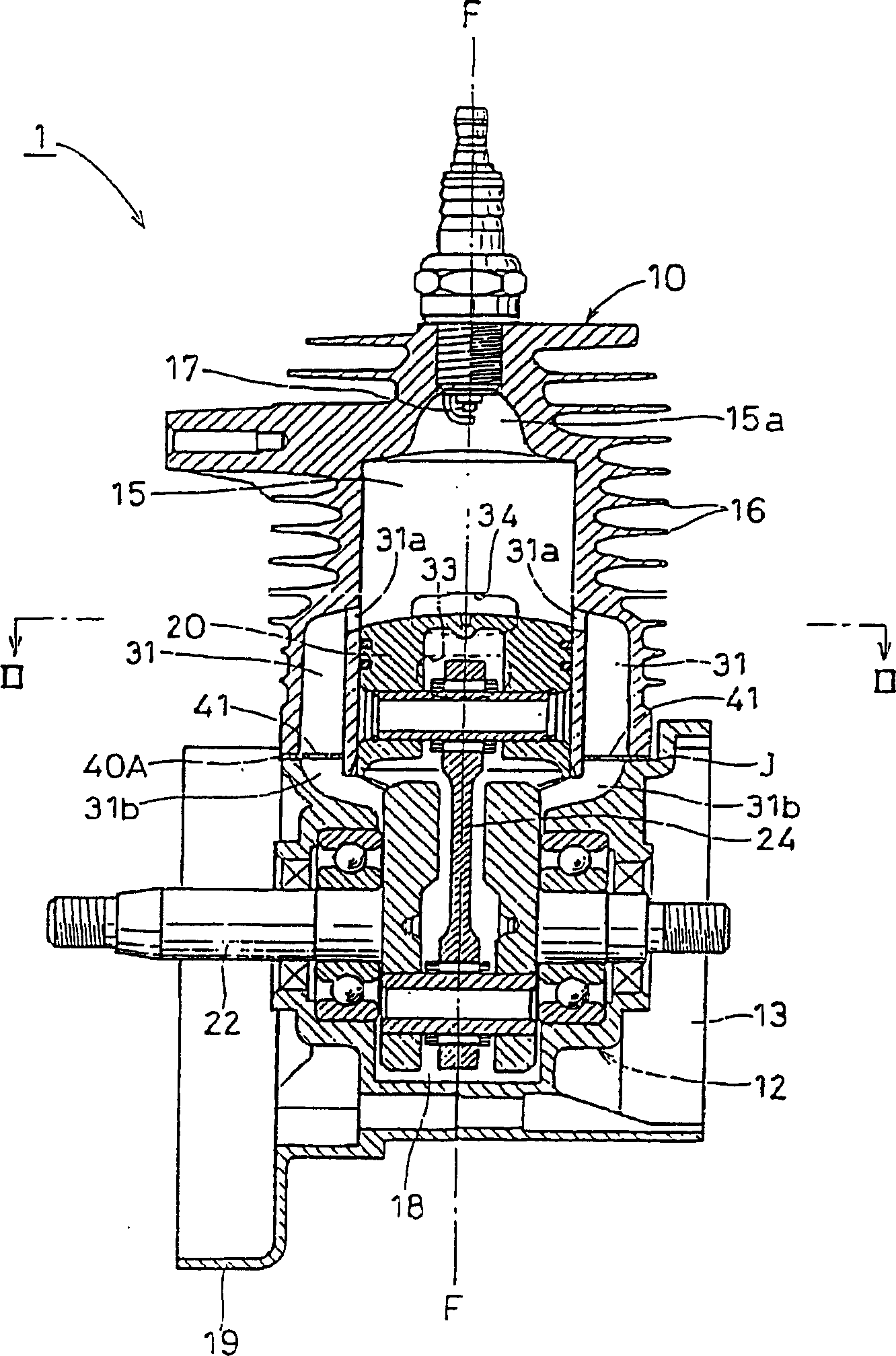

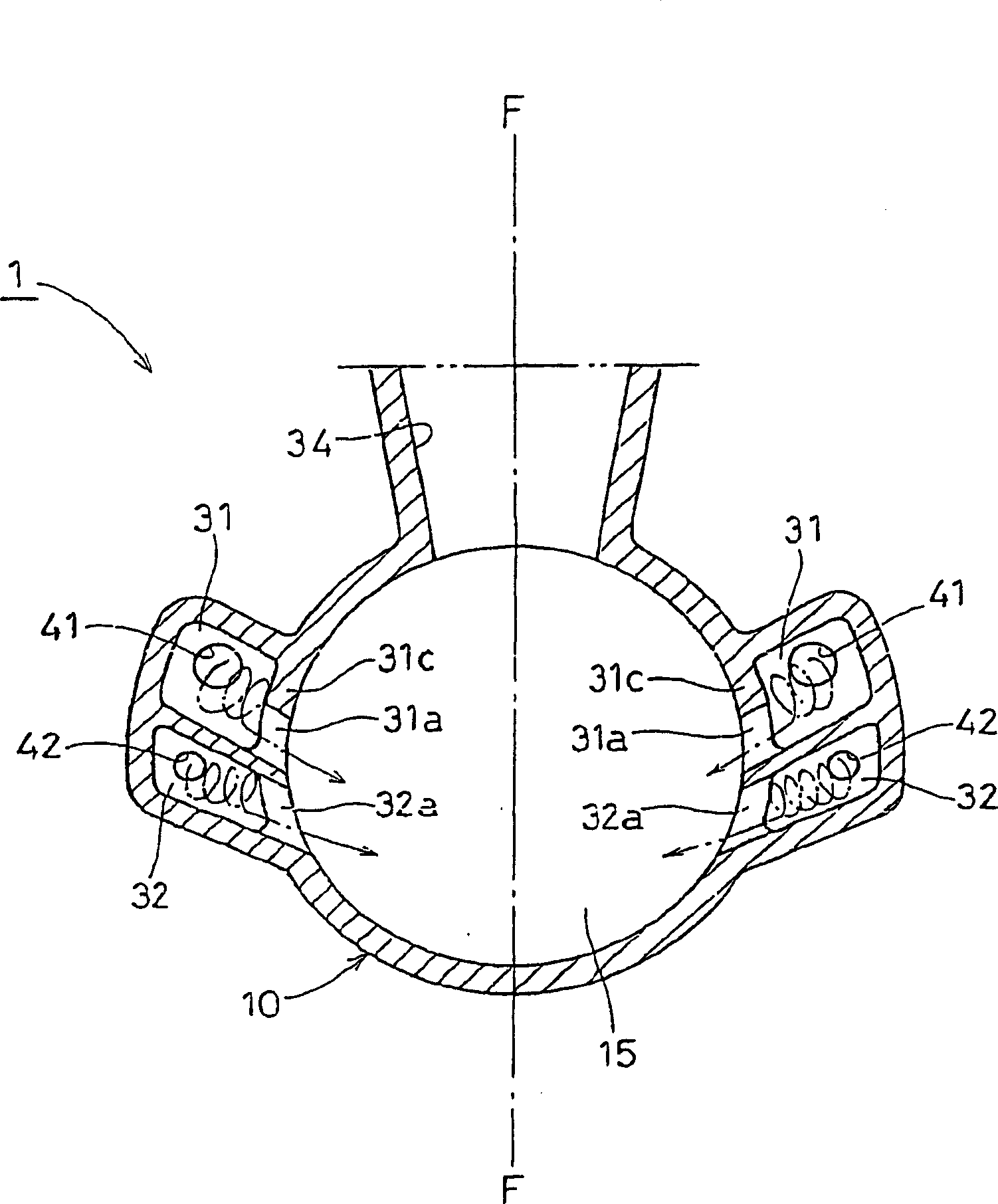

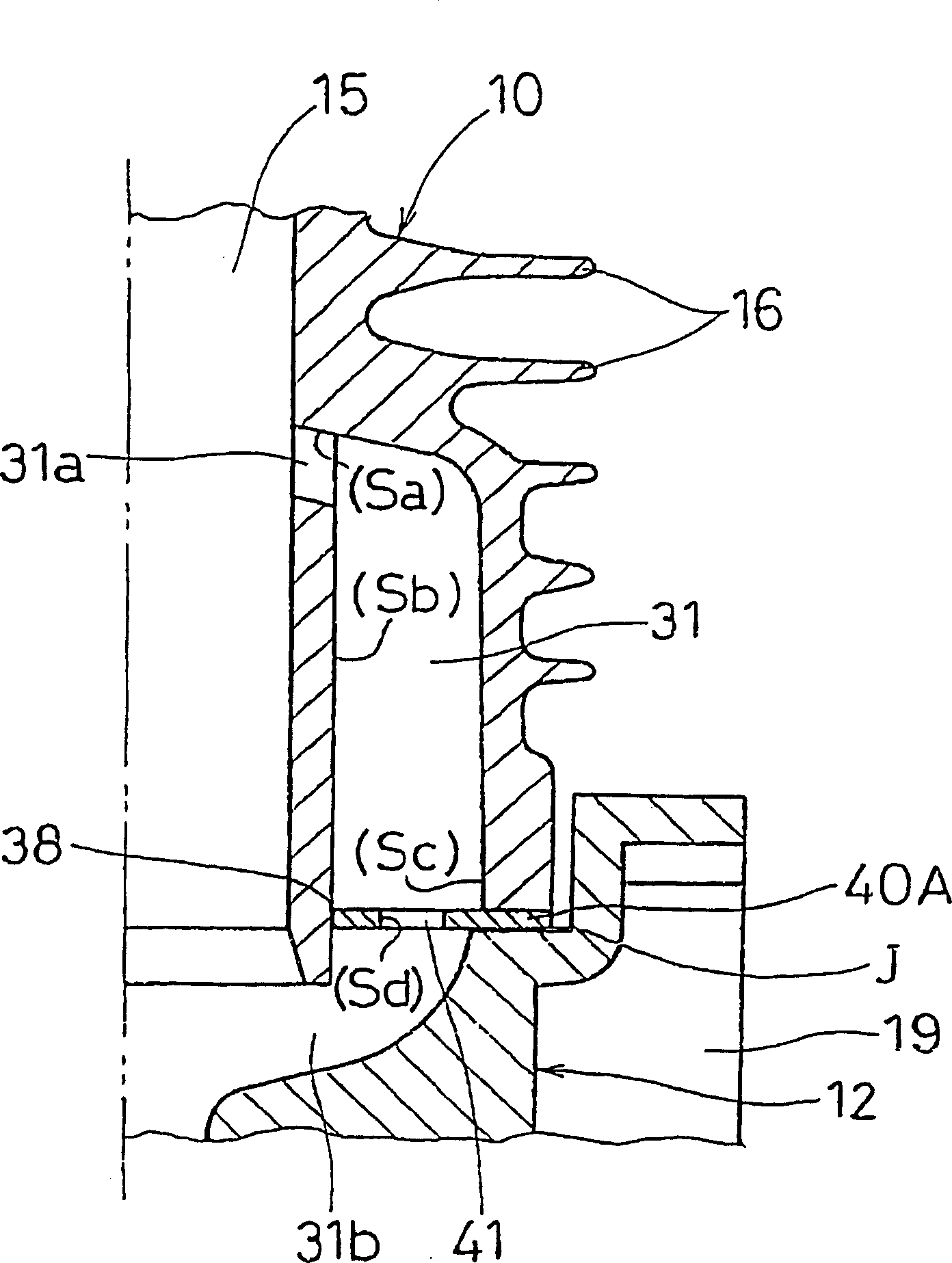

[0032] Such as figure 1 and figure 2As shown, the two-stroke internal combustion engine 1 according to the first embodiment is a small air-cooled two-stroke gasoline internal combustion engine with a four-way scavenging system, which is suitable for use in portable work tools. The engine 1 has a cylinder 10 and a two-piece crankcase 12, in which a piston 20 is accommodated in the cylinder 10, and the crankcase 12 is lined with a cylinder by four through-hole bolts (not shown). Pads 40A (to be described later) are fastened to the lower bottom surface of the cylinder 10, and four bolts are respectively inserted into four diagonal portions of these elements. Below the cylinder 10 , the crankcase 12 encloses a crank chamber 18 . The crankcase 12 rotatably supports a crankshaft 22 for reciprocating the piston 20 up and down through a connecting rod 24 .

[0033] A base part 13 of a recoil starter housing and a base part 19 of a fan housing are integrally connected to the left an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com