Gullet two stage shaping device of high pressure flexible pipe fixing sleeve

A technology for forming molds and high-pressure hoses, which is applied in the direction of hose connection devices, pipes/pipe joints/pipe fittings, mechanical equipment, etc., and can solve the problem of difficult extension of the extrusion flow direction, reduce the bite of the tooth groove 71, and the vertical extension of the tooth groove 71 Too much and other problems, to achieve good forming strength and increase the effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

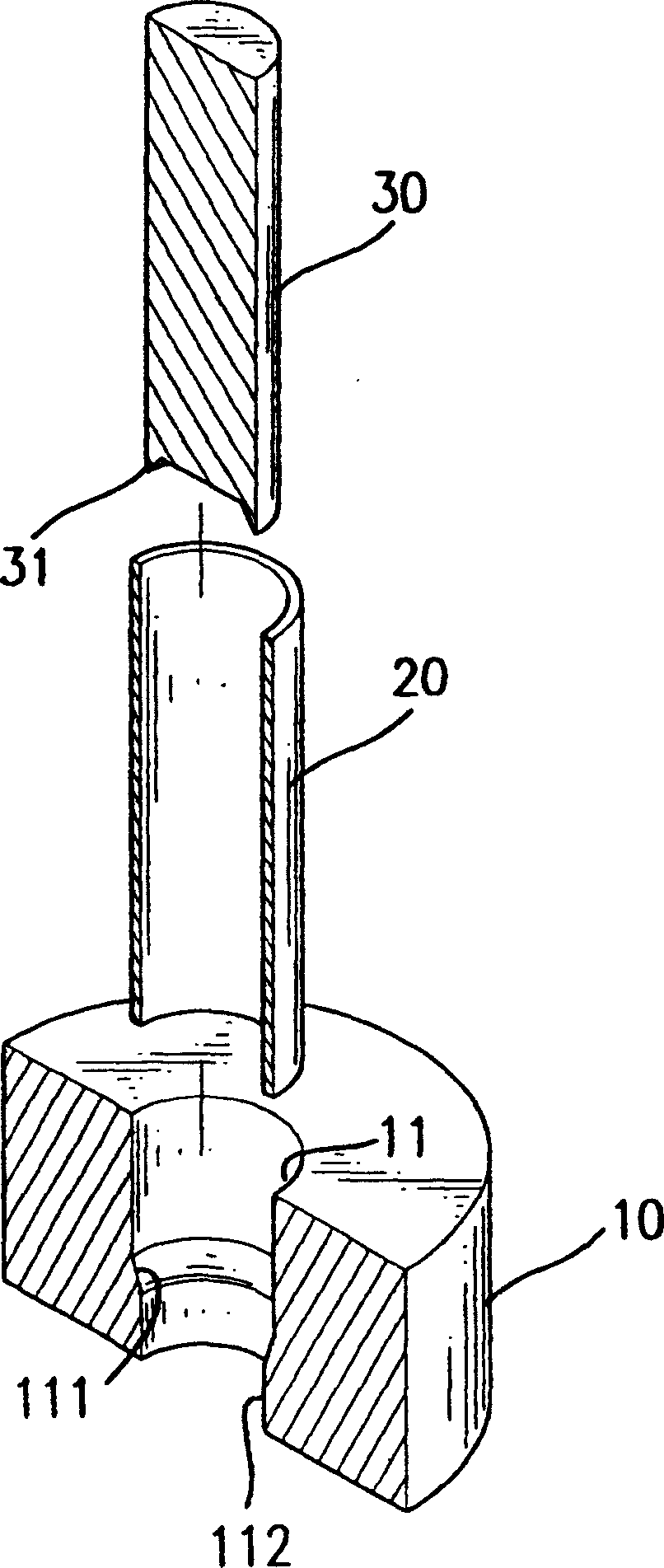

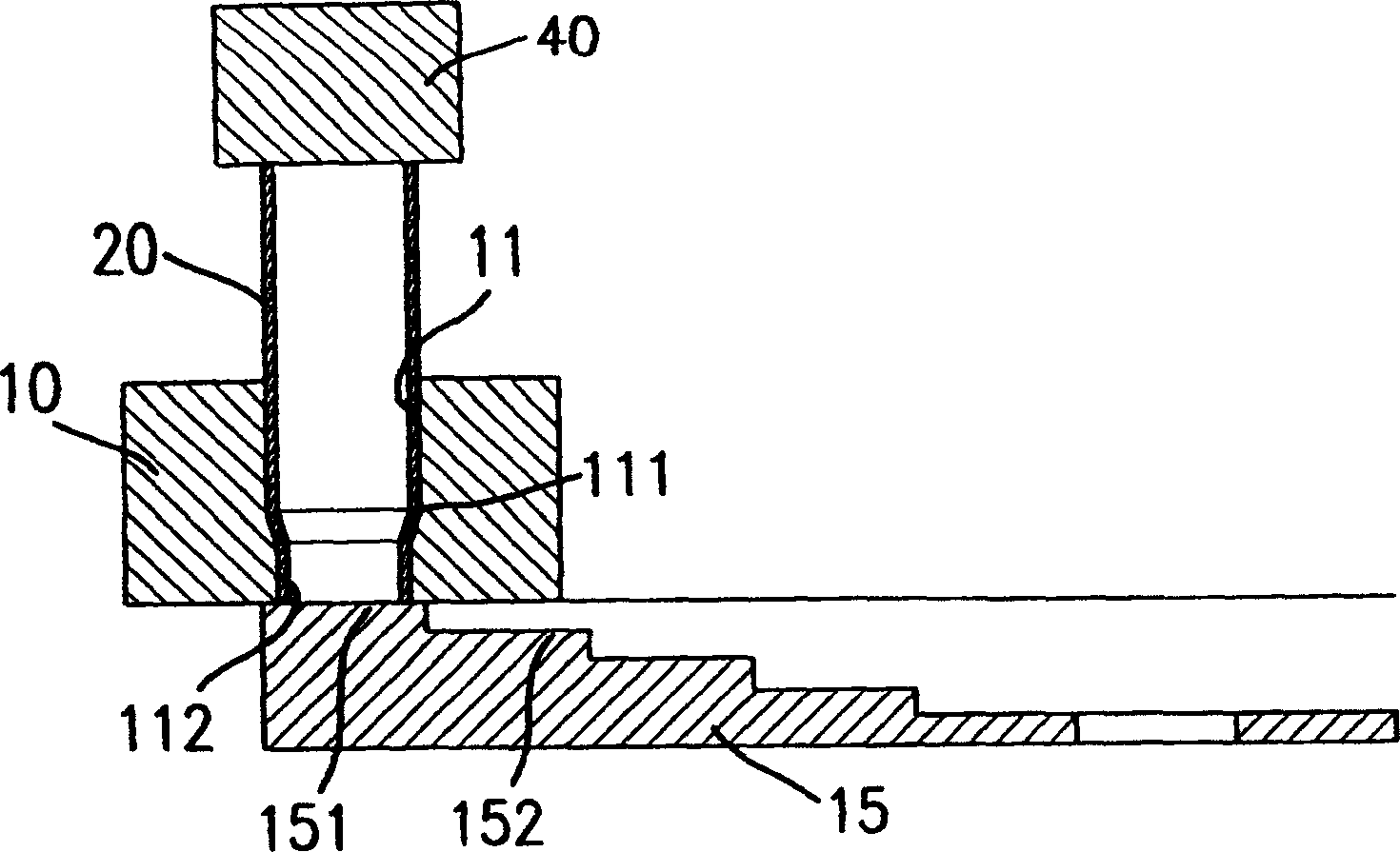

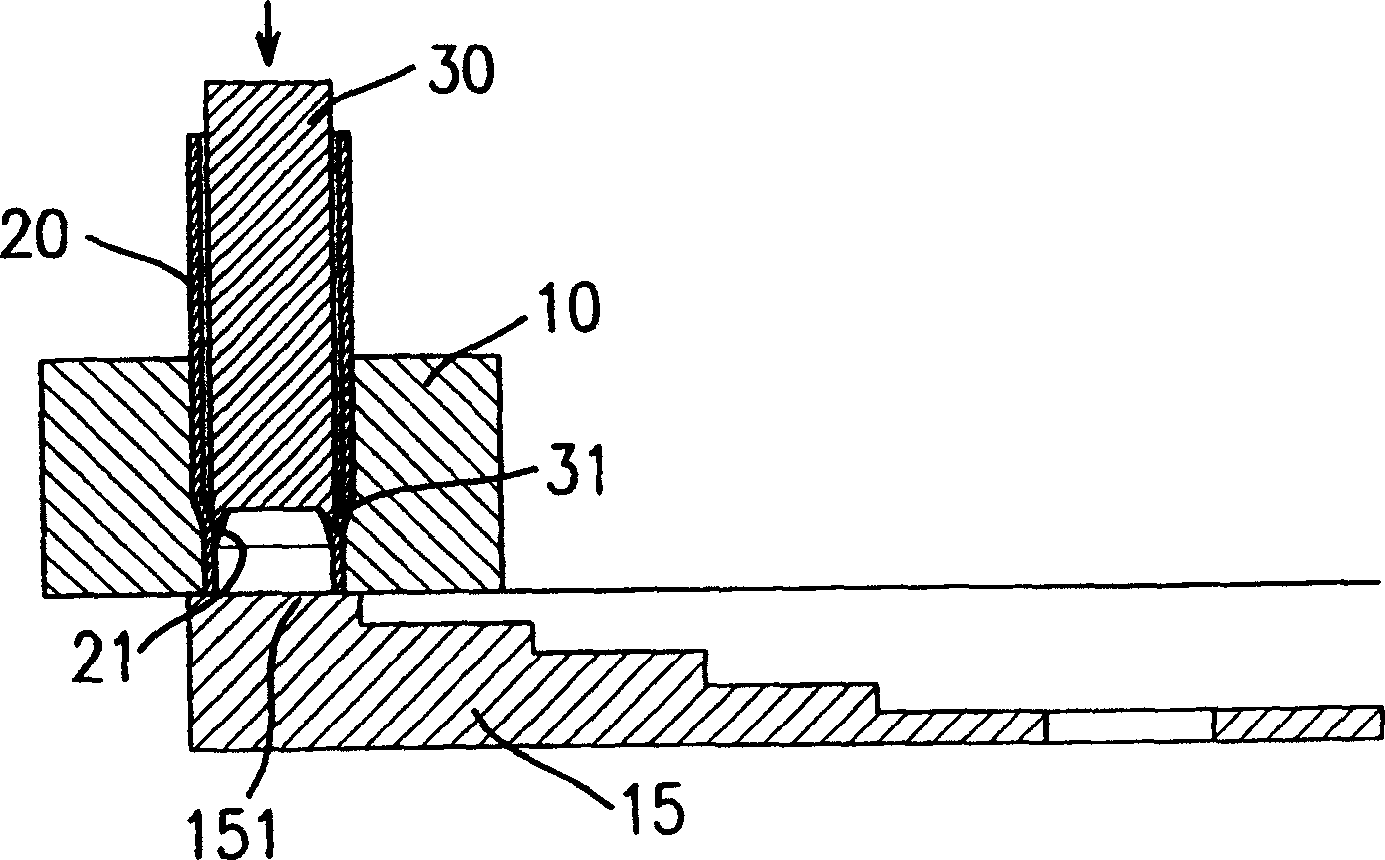

[0035] The present invention is a two-stage forming die device for a high-pressure hose fixed sleeve. Please refer to Figure 1 to Figure 8 , the present invention mainly includes a forming die 30 and a shaping die 50 to carry out a two-stage stamping process on the tooth groove of the fixed sleeve, so that the tooth groove 23 has good strength. The components are described in detail below.

[0036] The forming die 30 such as figure 1 As shown, the forming die 30 is a cylinder, and the axial section protruding downwards at one end peripheral edge has a shearing end 31 like a tiger's tooth; Figure 4 , the shaping die 50 is a cylinder, and an outer diameter is formed at one end than the shaping die 50 column body is a small rectifying pressure end 51.

[0037] Through the two-stage mold design of the present invention, the previous problems can be completely improved in implementation, such as Figure 2 to Figure 5 , which is to illustrate the implementation of using the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com