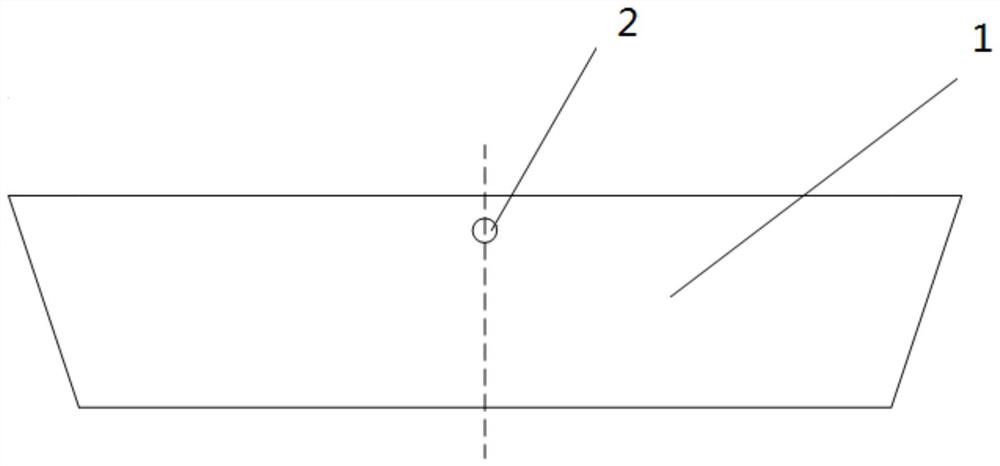

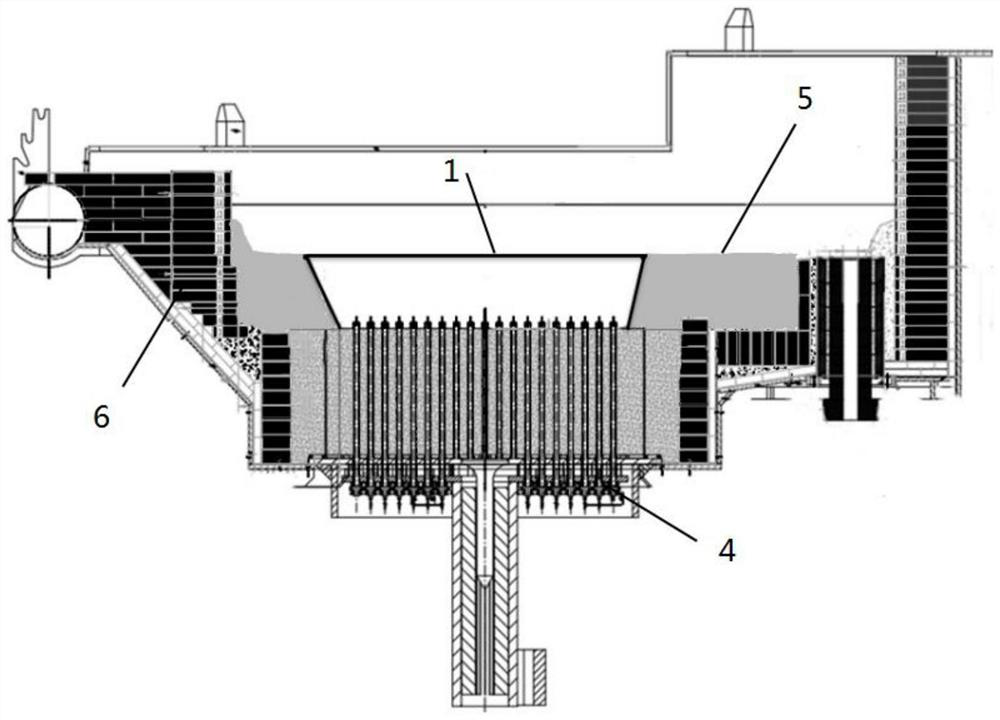

Furnace slope blank die and furnace slope building method of needle-type bottom electrode electric arc furnace

A bottom electrode and electric arc furnace technology, which is applied in the field of furnace manufacturing, can solve the problems of high manufacturing cost, long time consumption, and difficulty in forming the furnace slope of an electrode electric arc furnace, and achieves the effects of ensuring structural strength, avoiding rollover and facilitating processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

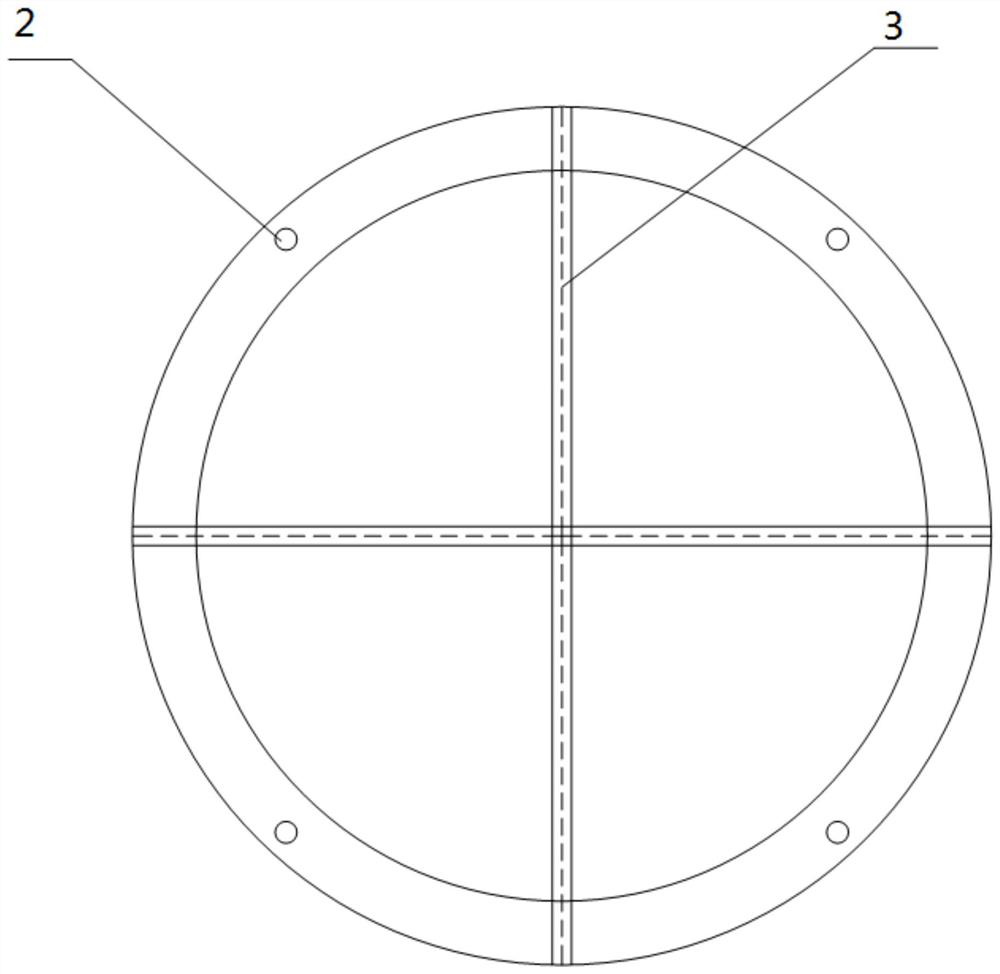

[0043] The specific embodiment 2 of the furnace slope membrane of the needle-type bottom electrode electric arc furnace of the present invention, the difference between this embodiment and the specific embodiment 1 is that in the specific embodiment 1, the hoisting and matching structure is set on the reducing tube the lifting hole. In this embodiment, lifting lugs are provided on the top of the reducing cylinder, and the lifting lugs cooperate with the lifting device to realize the hoisting of the tire membrane on the furnace slope, and the lifting lugs constitute a lifting matching structure.

specific Embodiment 3

[0044] The specific embodiment 3 of the furnace slope membrane of the needle-type bottom electrode electric arc furnace of the present invention, the difference of this embodiment with respect to the specific embodiment 1 is that in the specific embodiment 1, there are 4 hoisting holes, each hoisting hole along the The circumference of the reducer is uniformly arranged. In this embodiment, there are three hoisting holes, and each hoisting hole is evenly arranged along the circumferential direction of the reducing cylinder.

specific Embodiment 4

[0045] Specific embodiment 4 of the furnace slope membrane of the needle-type bottom electrode electric arc furnace of the present invention, the difference of this embodiment with respect to specific embodiment 1 is that in specific embodiment 1, there are 4 hoisting holes, and each hoisting hole is The circumference of the reducer is uniformly arranged. In this embodiment, there are five hoisting holes, and each hoisting hole is evenly arranged along the circumferential direction of the reducing cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com