Impact forming method for hydraulic valve end shield

A stamping and valve technology, applied in the field of metal stamping processing, can solve the problems of easy wrinkling and cracking, low yield and other problems, and achieve the effects of small internal structure deformation, high production efficiency and accurate size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

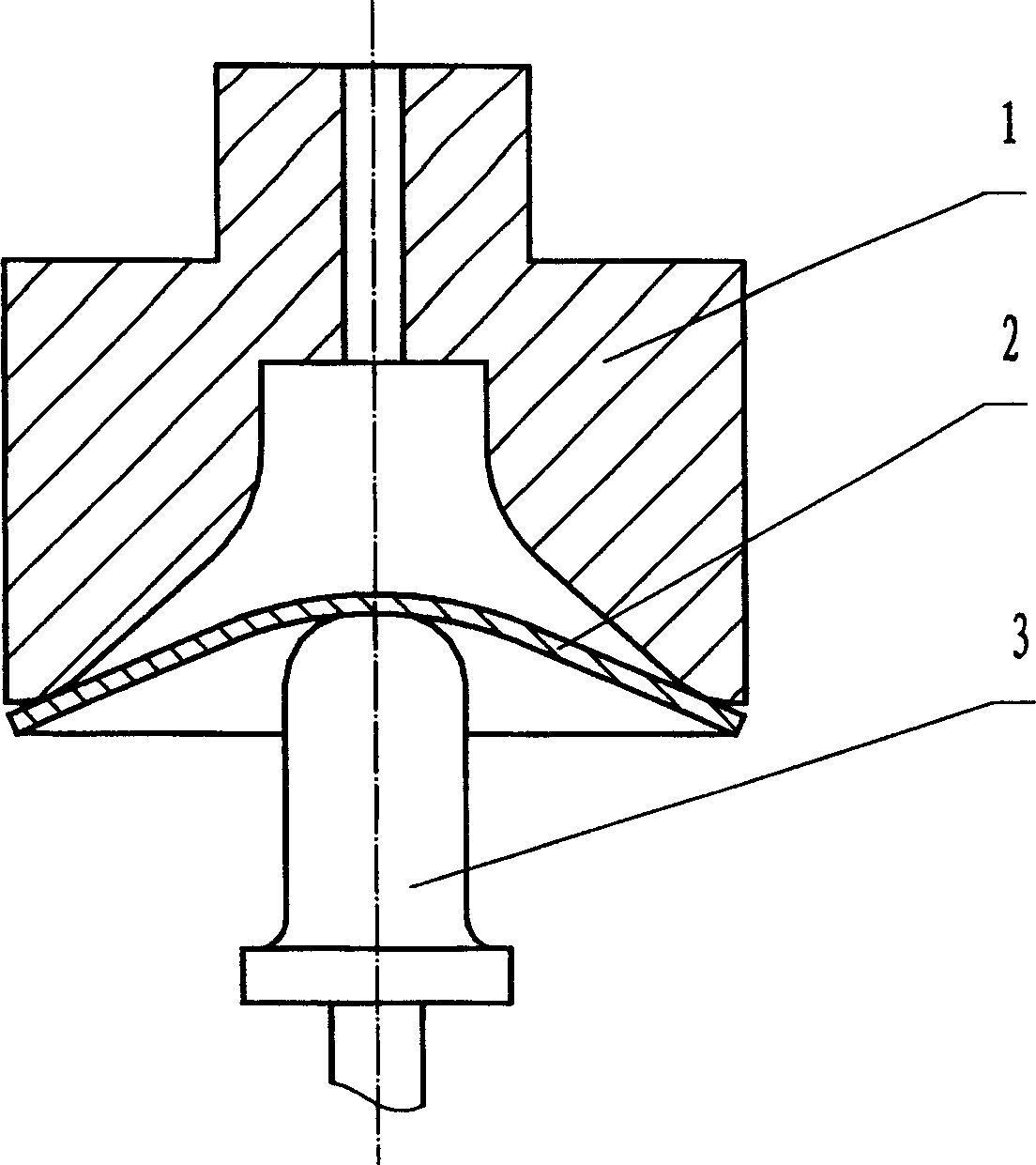

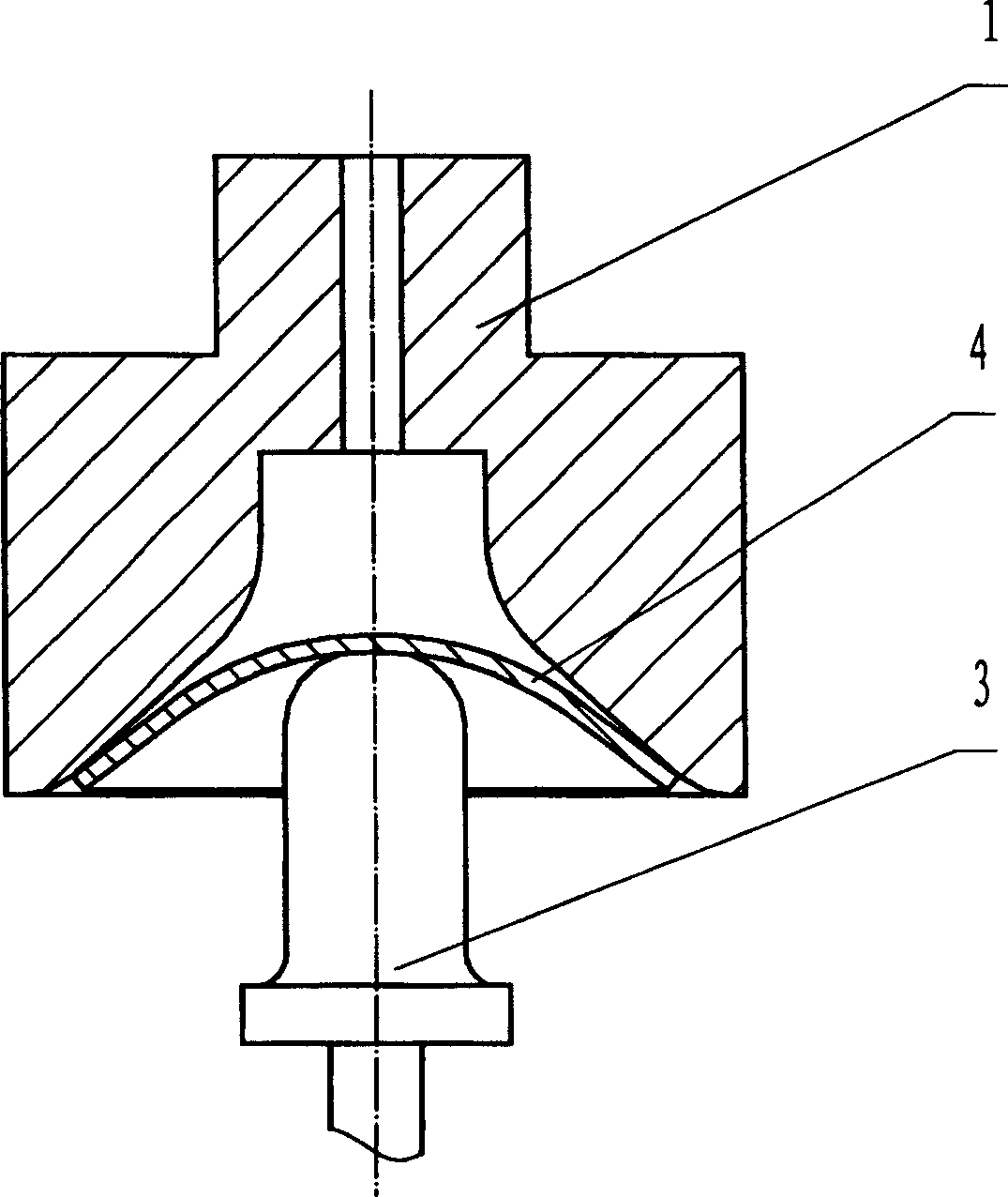

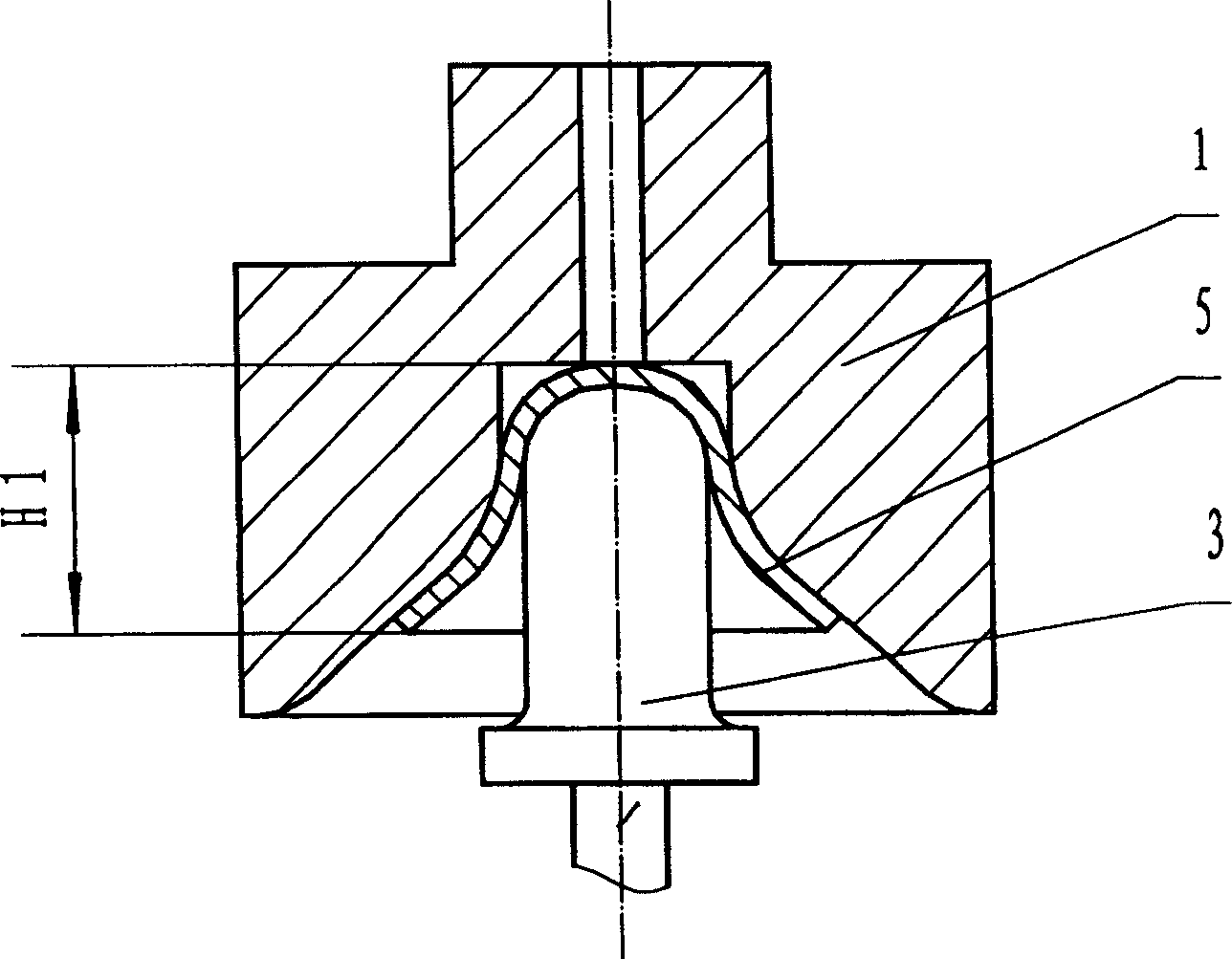

[0016] 1. Preliminary molding: Install the punch 3 on the workbench of the punching machine, install the conical die 1 on the punch of the punching machine, start the punching machine, and punch the sheet material into a spherical round cap blank 5. The spherical round cap blank 5 is completed through several times of punching, and the present invention uses three times of punching to complete, so as to avoid wrinkles on the surface of the workpiece blank. When the first punching and the second punching, the stroke of the punching machine should not be too large , the stroke of the stamping machine is too large, the sheet is easy to wrinkle, the first stamping will punch the sheet into a shallow spherical panel 2, such as figure 1 As shown, the second stamping presses the shallower spherical panel 2 into a deeper spherical panel 4, such as figure 2 As shown, the third stamping can stamp the deeper spherical face plate 4 into a spherical round cap blank 5, as image 3 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com