Soft multi-ply tissue paper having surface deposited strengthening agent

A surface-enhanced, tissue paper technology, applied in the directions of reinforcing agent addition, papermaking, adhesives, etc., can solve the problems of reinforcing multi-sheet products, not significantly increasing dry tensile strength, and not teaching sheet adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

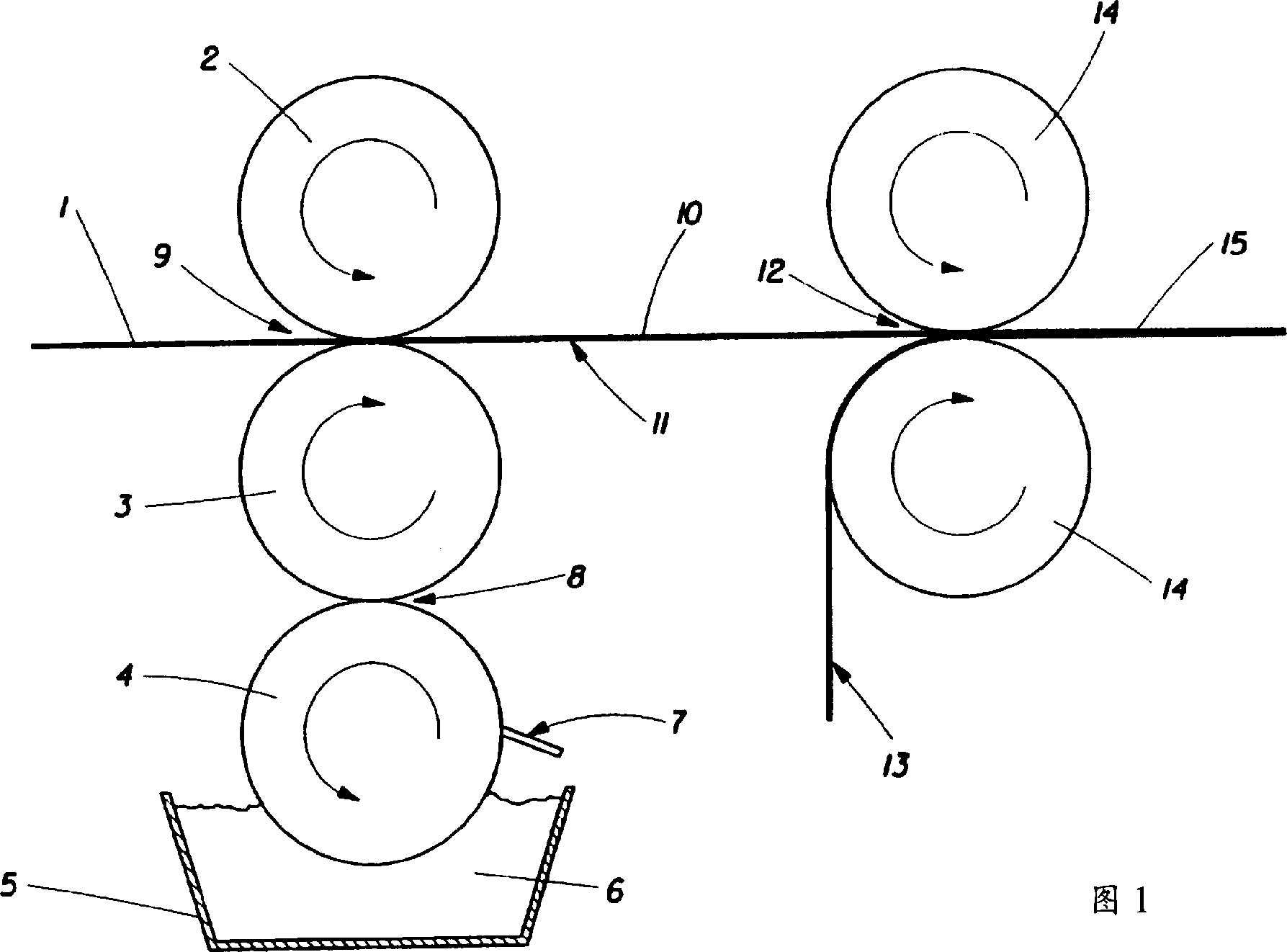

[0180] This example illustrates the use of a direct offset rotogravure press to prepare a two-ply bath tissue with a strengthening agent on the inner surface of one ply.

[0181] The reagent used to prepare the fluidization enhancer was a 45% solids acrylic latex (Rhoplex NW-2744F emulsion) obtained from Rohm & Hass, Philadelphia, Pennsylvania.

[0182] A fluidization enhancer was prepared by mixing 50% acrylic latex with 50% tap water to give a latex with a solids content of 23%. The fluidizing agent is then loaded into the gravure groove so that the fluidizing agent fills the recessed areas of the rotogravure cylinder.

[0183] The surface of the gravure cylinder is coated with alumina ceramics, and the concave area is carved in the alumina ceramics by laser technology. The recesses are hemispherical, each with a diameter of 55μ and a depth of about 228μ. The pattern of recessed areas was hexagonal with an occurrence rate of 350 per linear inch, resulting in approximately ...

Embodiment 2

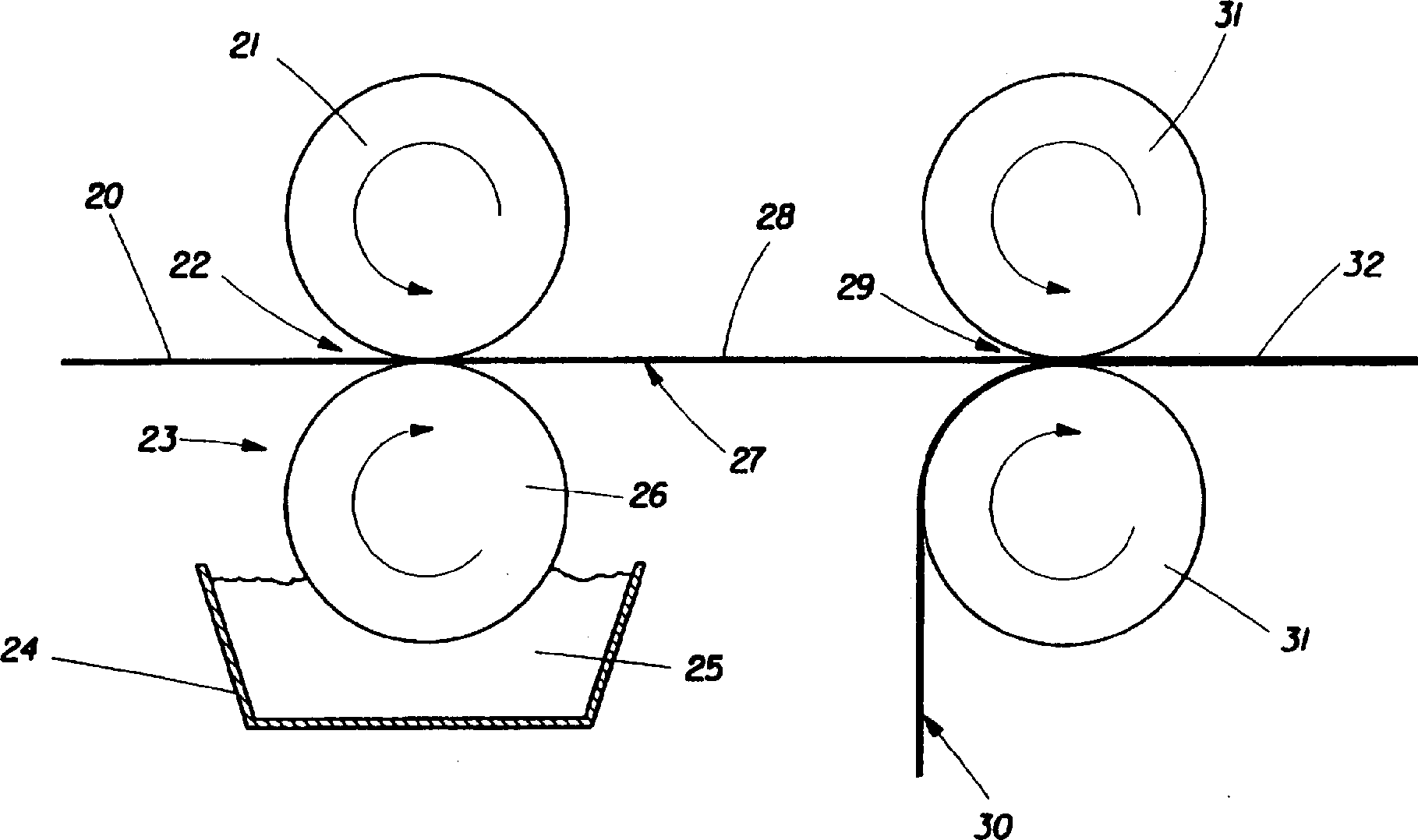

[0192] This example illustrates the use of a direct offset rotogravure press to prepare a two-ply bath tissue with reinforcing agent on the inner surfaces of both plies.

[0193] The reagent used to prepare the fluidization enhancer was a 44% solids acrylic latex (Rhoplex NW-1845 emulsion) obtained from Rohm & Hass, Philadelphia, Pennsylvania.

[0194] A fluidization enhancer was prepared by mixing 50% acrylic latex with 50% tap water to give a latex with a solids content of 22%. The fluidization enhancer is then charged into the gravure groove so that the fluidization enhancer fills the recessed areas of the rotogravure cylinder.

[0195] The surface of the gravure cylinder is coated with alumina ceramics, and the concave area is carved in the alumina ceramics by laser technology. The recesses are hemispherical, each with a diameter of 55μ and a depth of about 228μ. The pattern of recessed areas was hexagonal with an occurrence rate of 350 per linear inch, resulting in 140,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com