Process for preparing mesoporous Si-Al material and its preparing process

A silicon-alumina material and pore size technology, applied in the field of mesoporous silicon-alumina materials and their preparation, can solve the problems of different hydrolysis rates of alkoxides, expensive metal alkoxides, complicated preparation process, etc., and achieve enhanced accessibility and strong molecules. Cracking ability, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This example illustrates the preparation of the mesoporous silica-alumina material provided by the present invention.

[0032] Take 100ml concentration as 90gAl 2 o 3 / L Al 2 (SO 4 ) 3 Put the solution in a beaker, add ammonia water drop by drop under stirring conditions until the system pH = 8, and the neutralization and gelling temperature is 55°C; add 50ml of SiO with a content of 60g under stirring conditions 2 / L of water glass, heated to 80°C for 4 hours; use NH 4 Cl solution according to precipitate (dry basis): ammonium salt: H 2 The weight ratio of O=1:0.8:15, carry out ion-exchange to silicon-aluminum precipitate at 60 ℃ to remove the sodium ion therein, exchange repeats twice, carry out 0.5 hour each time, wash and filter after each exchange, Then dry at 120° C. for 15 hours, and bake at 600° C. for 3 hours to obtain the mesoporous silica-alumina material provided by the present invention. Abbreviated as SA-1.

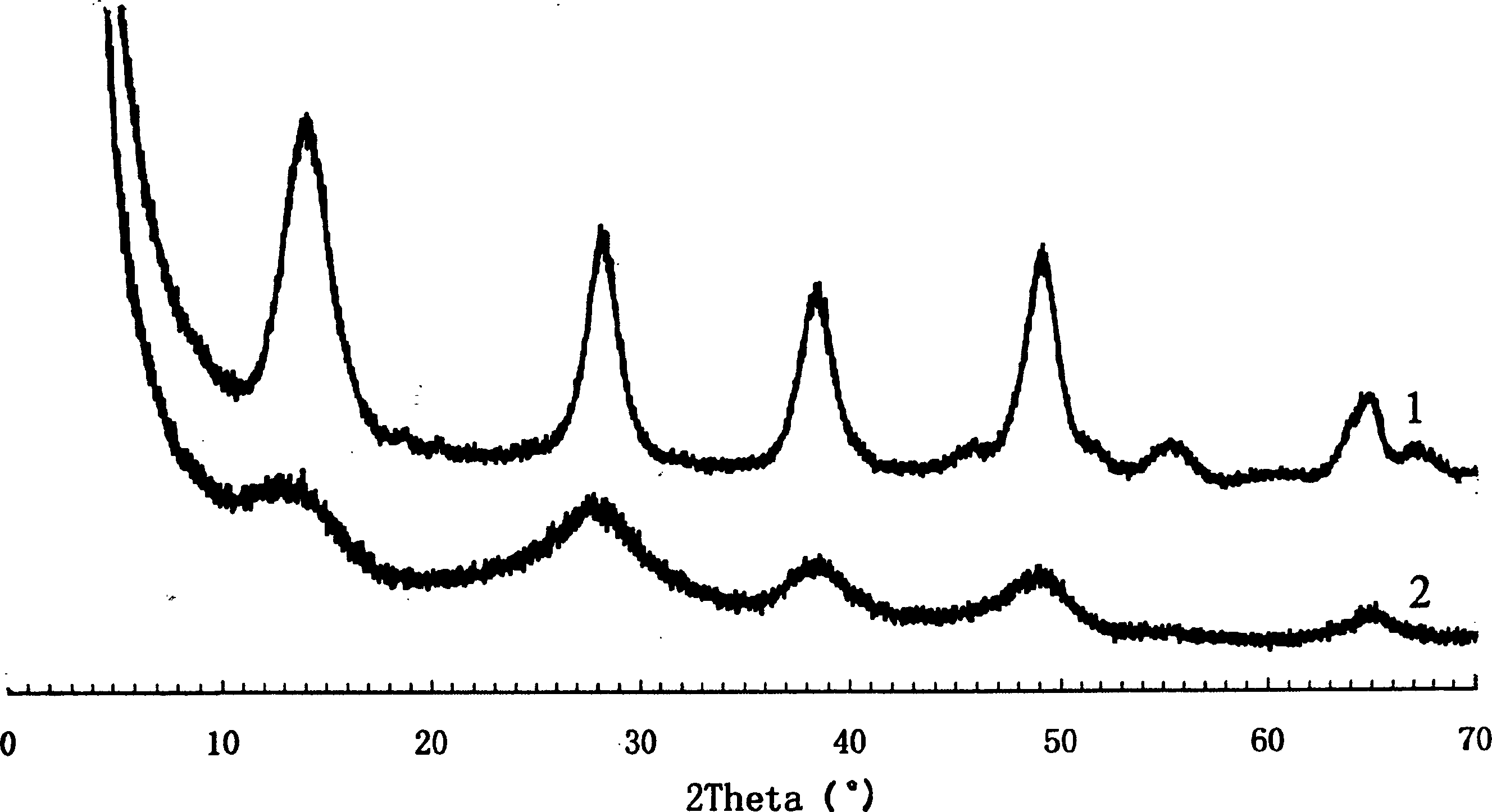

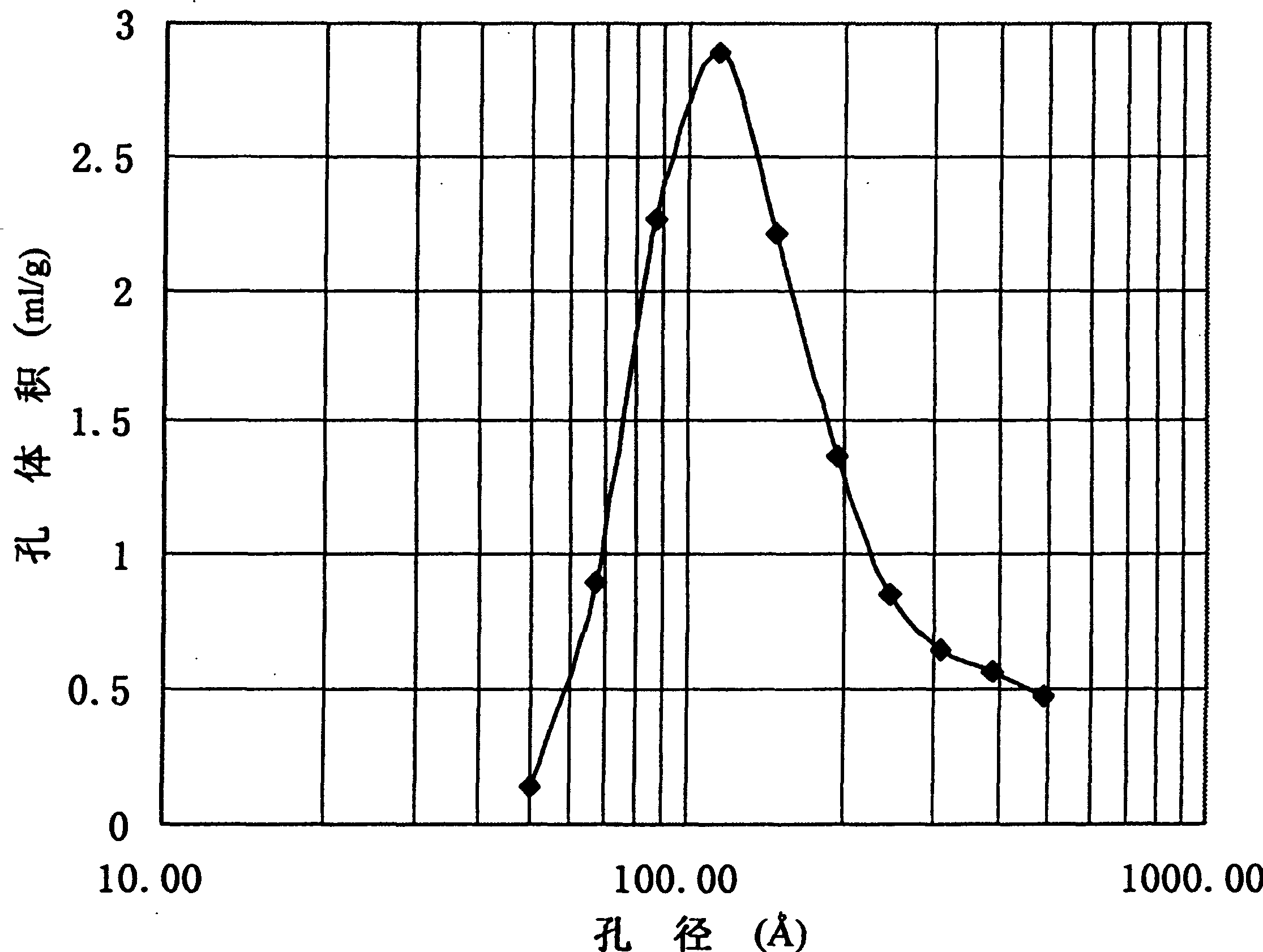

[0033] This sample has figure 1 The X-...

Embodiment 2

[0035] This example illustrates the preparation of the mesoporous silica-alumina material provided by the present invention.

[0036] Take 100ml concentration as 90gAl 2 o 3 / L Al 2 (SO 4 ) 3 Put the solution in a beaker, add ammonia water drop by drop under stirring conditions until the system pH = 8, and the neutralization and gelling temperature is 55°C; add 100ml of SiO with a content of 60g under stirring conditions 2 / L of water glass, heated to 80°C for 4 hours; use NH 4 Cl solution according to precipitate (dry basis): ammonium salt: H 2 The weight ratio of O=1:0.8:15, carry out ion-exchange to silicon-aluminum precipitate at 60 ℃ to remove the sodium ion therein, exchange repeats twice, carry out 0.5 hour each time, wash and filter after each exchange, Then dry at 120° C. for 15 hours, and bake at 600° C. for 3 hours to obtain the mesoporous silica-alumina material provided by the present invention. Abbreviated as SA-2.

[0037] This sample has figure 1 The X...

Embodiment 3

[0039] This example illustrates the preparation of the mesoporous silica-alumina material provided by the present invention.

[0040] Add a small amount of water to the beaker in advance to make the concentration 90gAl 2 o 3 / L Al 2 (SO 4 ) 3 The solution and ammonia water (10%) co-flow into a gel in a beaker, and the gelation temperature is 55°C, Al 2 (SO 4 ) 3 The flow rate of the solution is 20ml / min, and the gelation time is 5 minutes. Adjust the flow rate of ammonia water to keep the pH=7.5; after the gelation is completed, add 50ml of SiO with a content of 60g under stirring conditions. 2 / L of water glass, heated to 80°C for aging for 4 hours; use (NH 4 ) 2 CO 3 Solution according to precipitate (dry basis): ammonium salt: H 2 The weight ratio of O=1:0.8:15, carry out ion-exchange to silicon-aluminum precipitate at 60 ℃ to remove the sodium ion therein, exchange repeats twice, carry out 0.5 hour each time, wash and filter after each exchange, Then dry at 120°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com