Manufacturing method of semiconductor laser device

A technology of laser devices and manufacturing methods, which is applied in the direction of semiconductor laser devices, semiconductor lasers, and structural details of semiconductor lasers, and can solve problems such as reducing printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

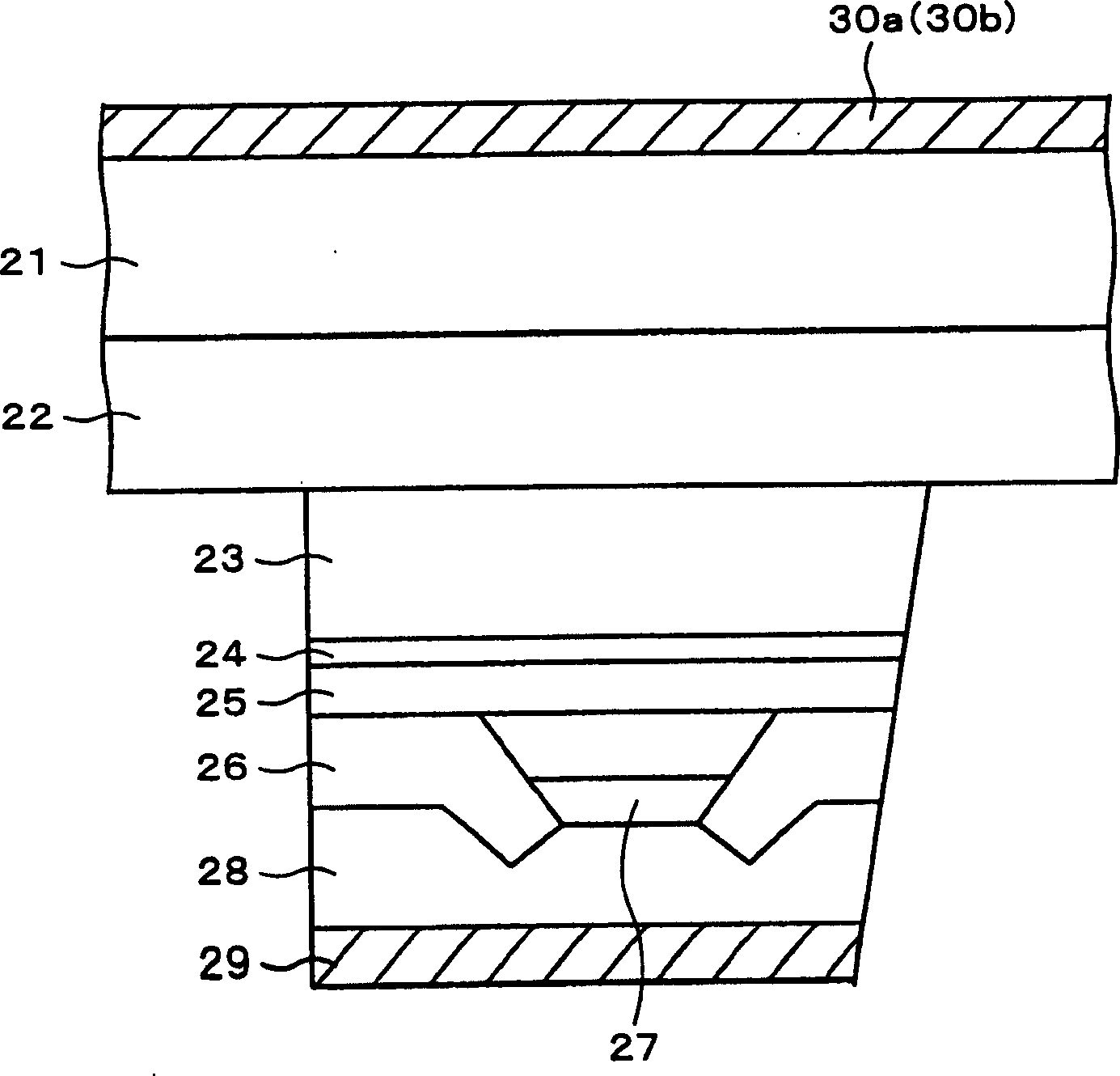

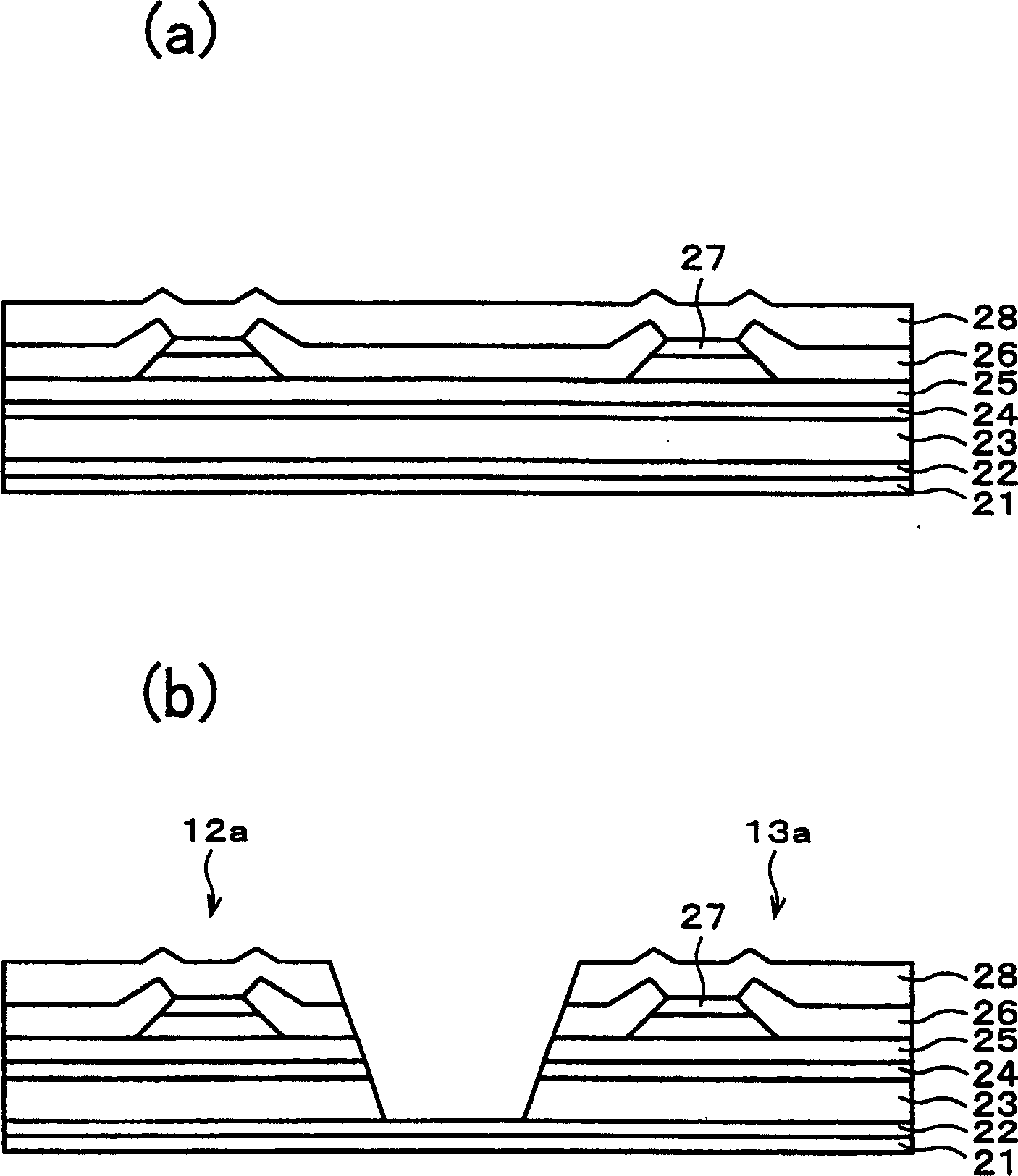

[0059] One embodiment of the present invention will be described below.

[0060] The semiconductor laser device (this laser device) according to this embodiment is a multi-beam laser device capable of simultaneously emitting two laser beams.

[0061] Moreover, this device can be used in electronic equipment such as a player capable of reproducing both CD (compact disc) and DVD (digital versatile disc), and a laser beam printer (digital copier, etc.) that exposes a photoreceptor by two types of laser light.

[0062] First, the configuration of this laser device will be described.

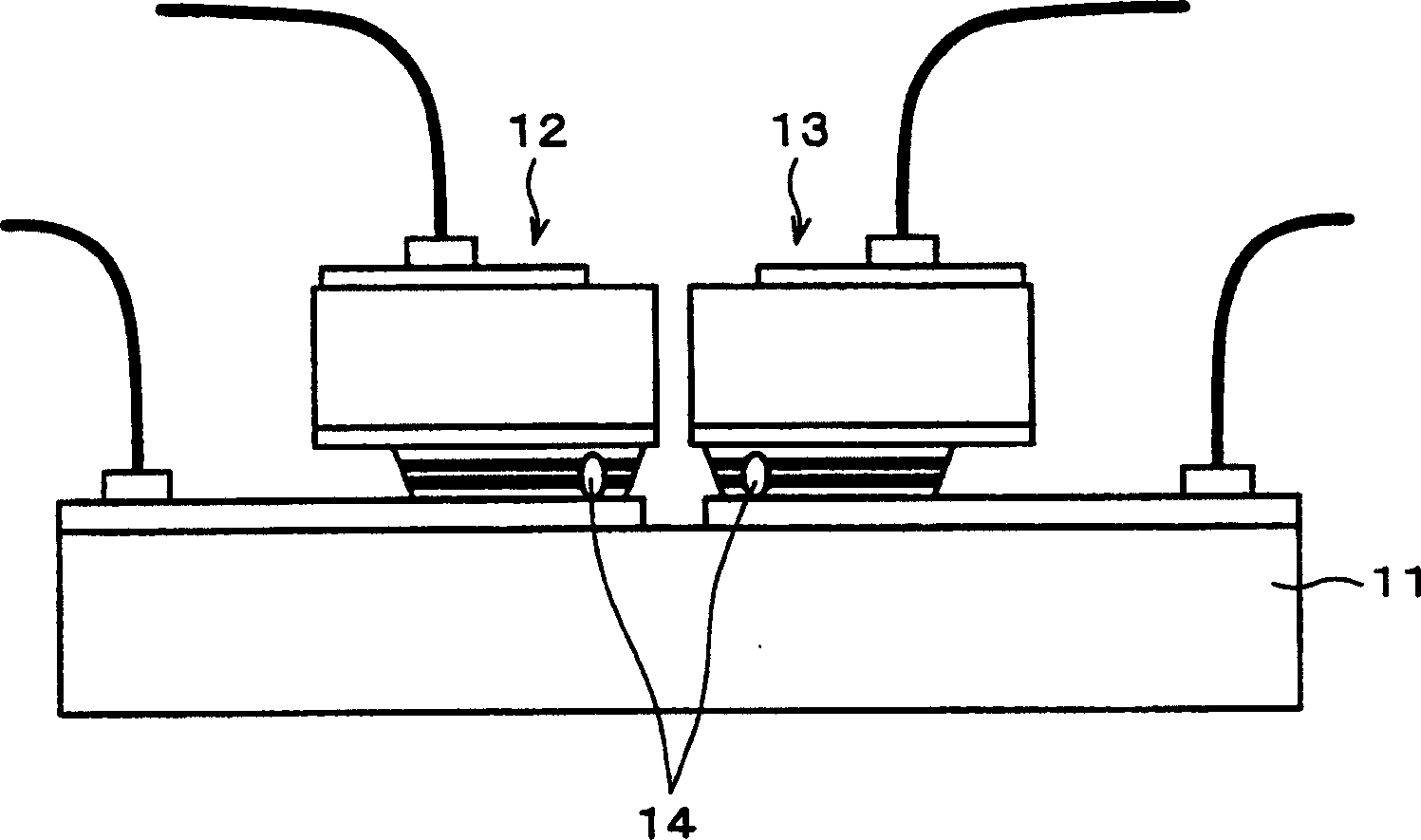

[0063] figure 1 It is an explanatory diagram of the structure of this laser device.

[0064] As shown in the figure, the first semiconductor laser element 12 and the second semiconductor laser element 13 are mounted on a submount (submount substrate) 11 formed of insulating SiC.

[0065] In addition, the present laser device outputs laser light from respective light-emitting points (oscillating r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| luminous point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com