Semiconductor laser component

A technology of laser components and semiconductors, applied in semiconductor lasers, laser parts, lasers, etc., can solve the problems of unstable film thickness, poor reproducibility, and poor effective refractive index of the refractive index control layer 9, and achieve improved film thickness control Excellent reproducibility and high manufacturing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

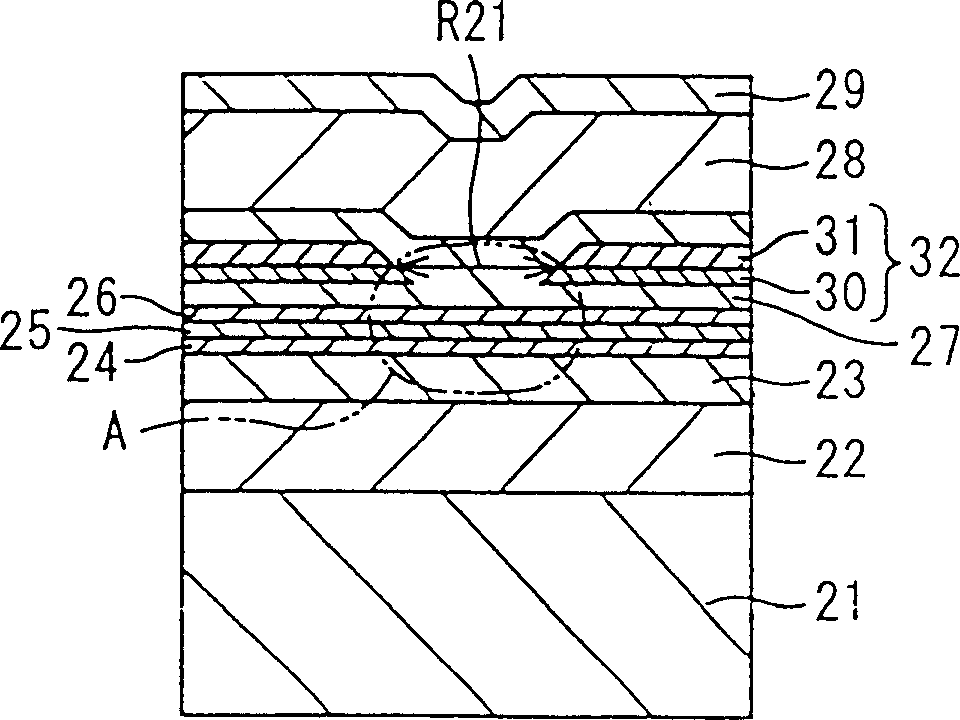

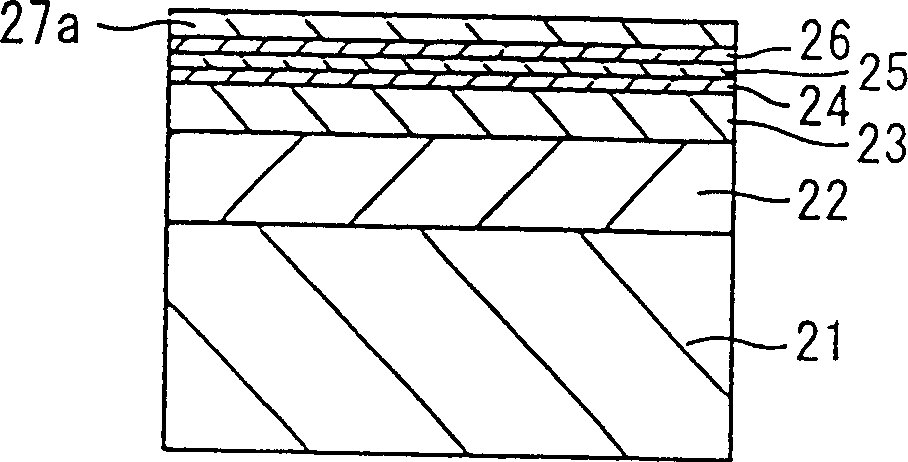

[0024] figure 1 It is a cross-sectional view showing the structure of a semiconductor laser element according to an embodiment of the present invention. In this embodiment, a DCH-SAS laser element using a semiconductor buffer layer is taken as an example for description. The semiconductor laser element is made of n-type Al on the n-type GaAs substrate 21. 0.09 Ga 0.91 As cladding layer 22, n-type GaAs optical waveguide layer 23, n-type Al 0.40 Ga 0.60 As carrier blocking layer 24, In 0.18 Ga 0.82 As / GaAs quantum well active layer 25, p-type Al 0.40 Ga 0.60 As carrier blocking layer 26, p-type GaAs optical waveguide layer 27, p-type Al 0.09 Ga 0.91 The As cladding layer 28 and the p-type GaAs contact layer 29 are stacked in this order.

[0025] In the semiconductor laser element, the light emitted from the active layer 25 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com