Germanium chloride and siloxane feedstock for forming silica glass and method

A kind of technology of germanium chloride and siloxane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

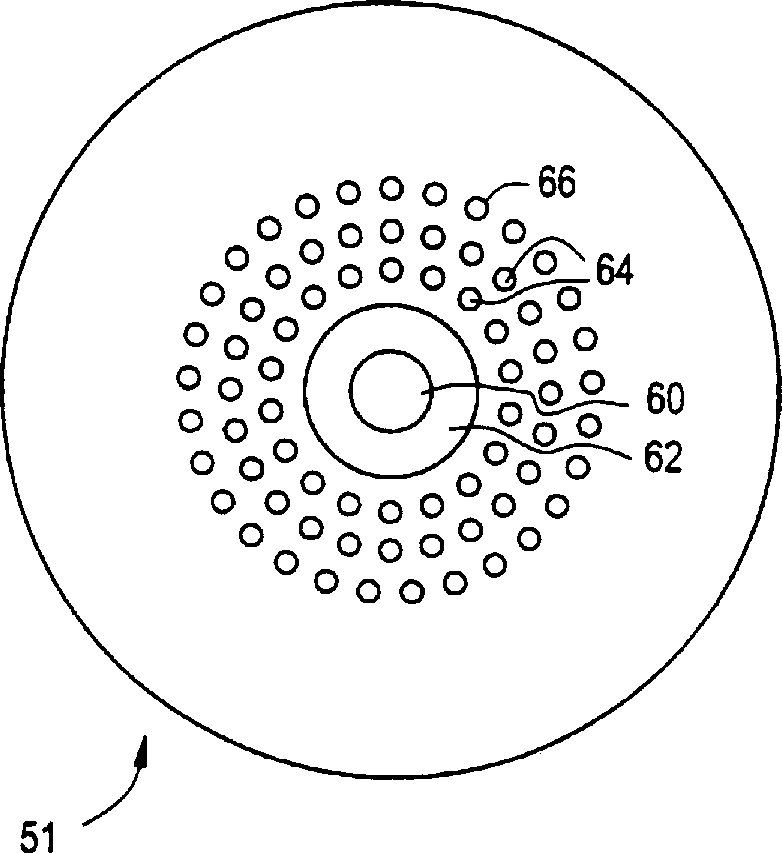

[0040] use the following table figure 1 with 2 The system and apparatus shown for the preparation of GeO-doped 2 SiO 2 soot. High-purity liquid octamethylcyclotetrasiloxane containing at least 95% by weight octamethylcyclotetrasiloxane is pumped from vessel 20 into a ramped flash tank heated to a temperature above the boiling point of octamethylcyclotetrasiloxane. Steamer 26. Octamethylcyclotetrasiloxane vapor is delivered to conversion site 30 by nitrogen carrier gas from nitrogen source 28 . Feed pipes 32, 50 and 40 and pipe fittings 38 and 42 are made of stainless steel pipe. These pipes are heated to 190°C. Oxygen heated to about 200° C. is delivered by oxygen source 34 and heated tubing 36 to connection 38 . High-purity GeCl 4 The steam is mixed with octamethylcyclotetrasiloxane at feed connection 42 . GeCl 4 Steam from GeCl 4 Evaporator 44 supply. GeCl 4 The evaporator 44 consists of a GeCl 4 Bubbler. Will be packed in container 48 containing at least 99% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com