Making process of intrauterine medicine releasing device

A technology for releasing medicine and medicine palace, which is applied in the field of preparation of medicine-containing intrauterine medicine releaser, can solve the problems such as difficulty for enterprises to achieve, high requirements for production environment, high price of injection molding vulcanizing machine, etc., and achieves low cost and scope of application. Wide and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

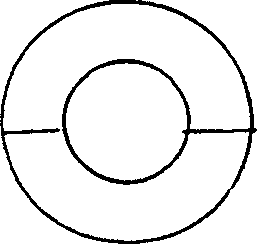

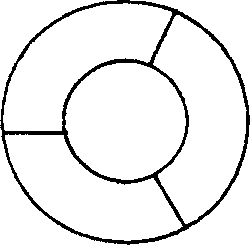

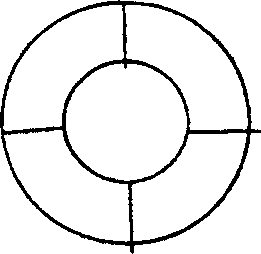

Image

Examples

Embodiment 1

[0062] Embodiment 1, containing LNG-IUD

[0063] (1) Weigh 20g of LTV (liquid addition forming) silicone rubber, 20g of levonorgestrel, appropriate amount of platinum catalyst and active hydrogen cross-linking agent, put them into a mold and hot press to form a semicircular drug-containing layer valve , hot-pressed and vulcanized into drug-containing layer petals, trimmed, cut to a length of 1.9cm, and a weight of 45-47mg per petal.

[0064] (2) Take the polyethylene IUD plastic bracket and soak it in absolute ethanol for two hours, drain it and set it aside.

[0065] (3) Adhere the drug layer valve that meets the requirements with the IUD stent after slight friction, put the outer silicon rubber controlled release tube into a glass vessel, swell it with chloroform to more than double the original volume, and then Put it into the outer layer of the valve containing the cylindrical drug layer, and after it volatilizes naturally, the outer layer of silicon rubber controlled rel...

Embodiment 2

[0066] Example 2 Gestodene-containing -IUD

[0067] (1) Mix gestodene and medical grade LS-4100 addition type silicone rubber 1:1 uniformly on the rubber mixer, put it into a 1 / 3 semicircular mold, hot press and vulcanize to form a drug-containing layer flap, trim the edge , the interception length is 1.9cm and the weight is 17mg / per petal.

[0068] (2) Gently rubbing and covering the two semicircular drug-containing layer flaps on the longitudinal arm of the IUD stent, and then continuously dipping in 10% EVAC: chloroform controlled-release dipping membrane solution, Volatile, film 4 times. Then put the outer silicone rubber controlled-release tube into a glass container, swell it with chloroform to more than double its original volume, and then put it into the outer layer containing the cylindrical drug layer flap, and wait for it to volatilize naturally , combined into a complex reservoir type and a rate-controlled release membrane multiple controlled drug release system....

Embodiment 3

[0069] Example 3: IUDs containing mifepristone

[0070] (1) Mix mifepristone and medical grade LS-4100 addition type silicone rubber 1:1 uniformly on the rubber mixer, press it into a cylindrical shape through a mold, and vulcanize it by hot pressing to form a drug-containing layer. The drug-containing layer is thick 0.75mm, inner diameter 1.5mm, outer diameter 3mm, then trimmed, and cut out a cylindrical drug-containing layer with a length of 1.9cm and a weight of 92mg.

[0071] (2) Put the cylindrical drug-containing layer on the longitudinal arm of the IUD stent, and then continuously dip in 10% EVAC: chloroform controlled-release impregnation membrane solution for dipping, volatilization, and film formation twice. After the solvent is completely volatilized naturally, it is combined into a dual controlled drug release system of composite storage type and rate controlled release membrane. This embodiment is also applicable to the preparation of some difficult-to-dissolve p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com