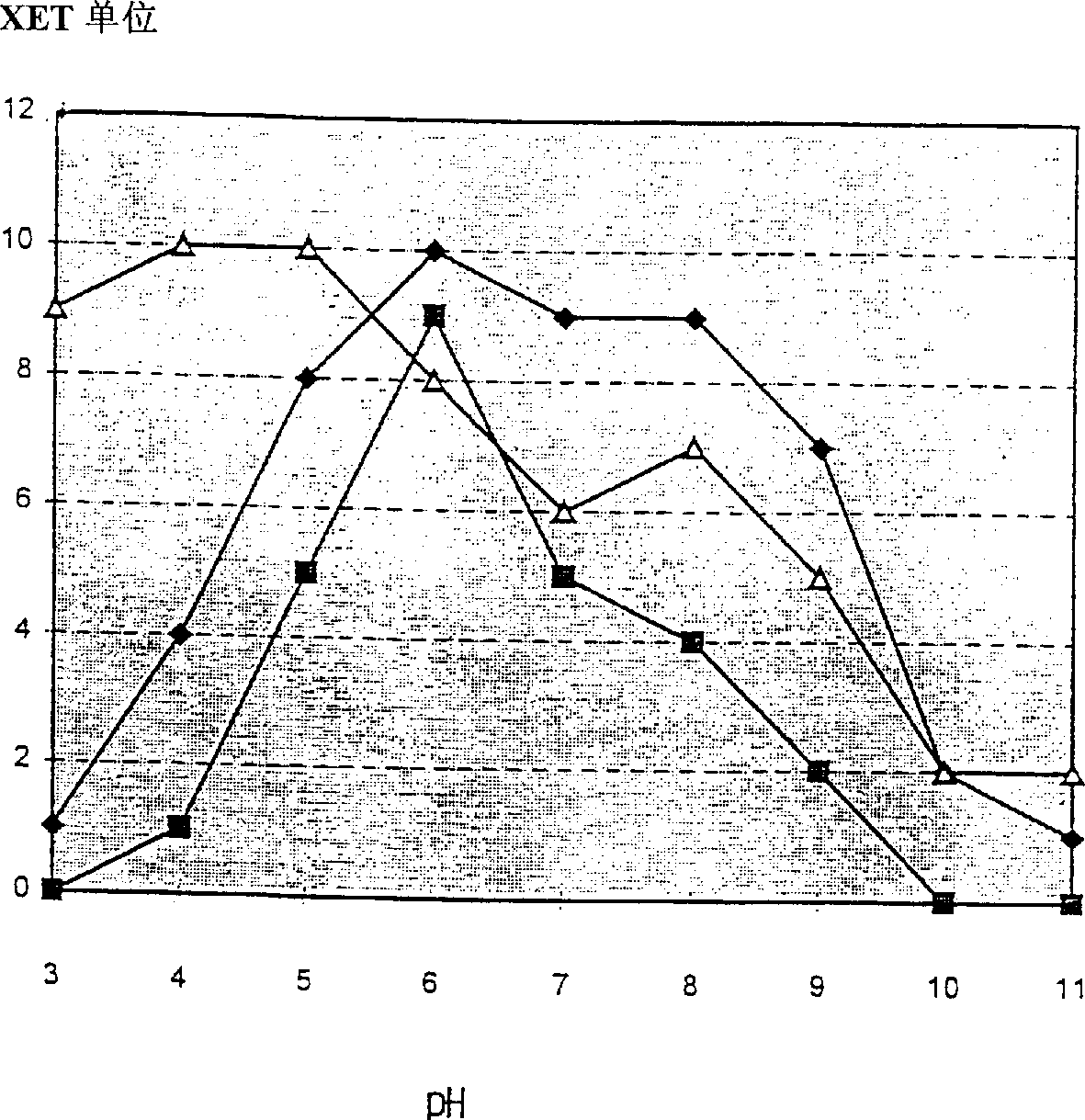

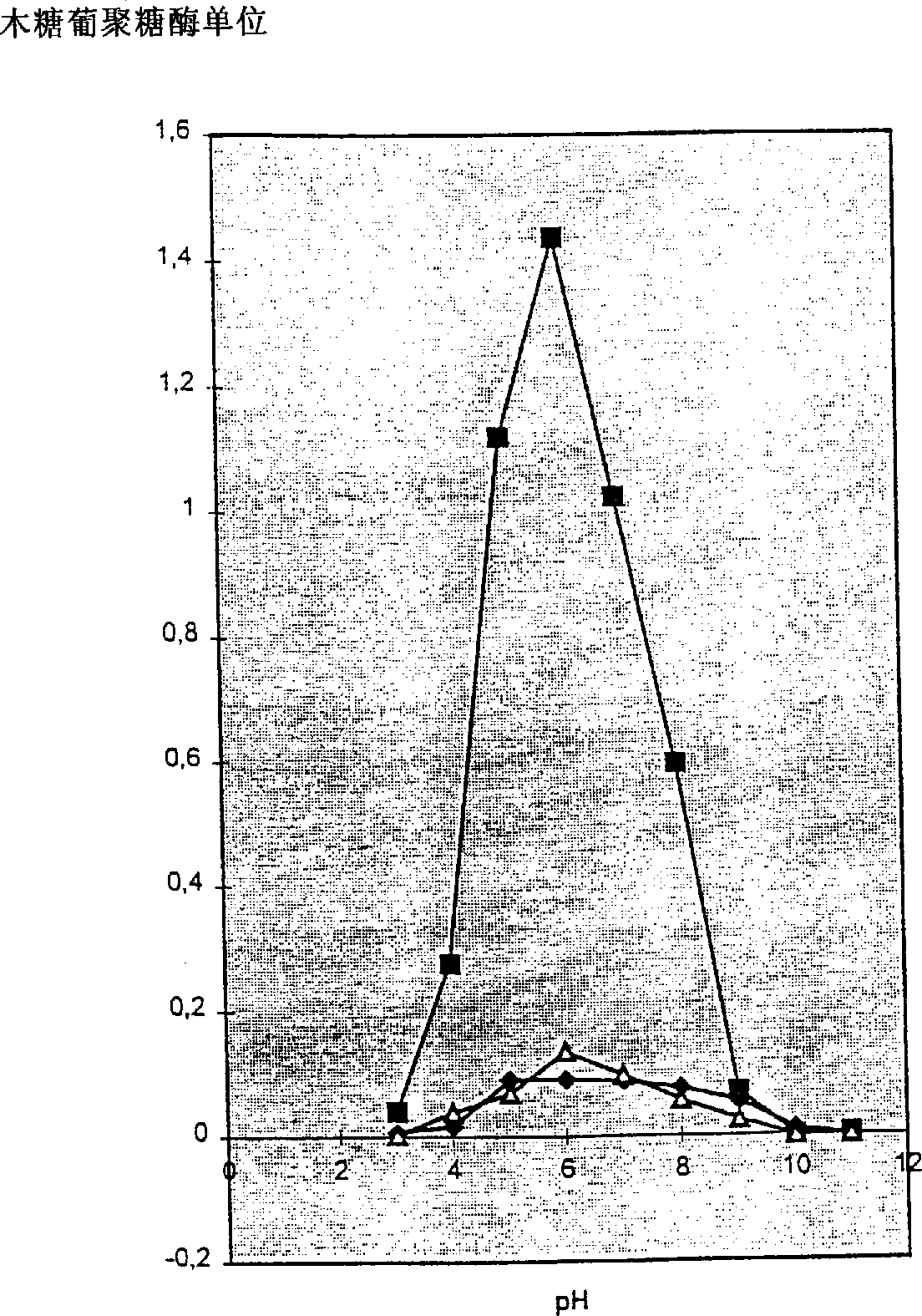

Microbial xyloglucan Endotransglycosylase (XET)

A technology of xyloglucan and glycosylase, applied in the directions of microorganisms, microorganism-based methods, transferases, etc., can solve problems such as XET that have not been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0177] Embodiment 1: screening XET positive bacterial strain

[0178] culture medium

[0179] PD agar: 39g potato dextrose agar, DIFCO 0013; add deionized water to 1000ml, autoclave at 121°C for 15-20 minutes.

[0180] YPG agar: 4g yeast extract (DIFCO 0127), 1g KH 2 PO 4 (Merck4873), 0.5g MgSO 4 ·7H 2 O (Merck5886), 15g glucose (Roquette 101-0441), 20g agar (Merck1614), make up to 1000ml with deionized water, and sterilize by high pressure steam at 121°C for 15-20 minutes.

[0181] MEA: 20g malt extract powder (DIFC00186), 1g peptone (DIFC00118), 20g glucose (Roquette France 1010441), 20g agar (Merck1614), make up to 1000ml with deionized water, and autoclave at 121°C for 15 minutes.

[0182] Medium A (per bottle): 30g wheat bran, 45ml of the following solution: 10g rofec (Roquette 101-0441), 10g NH 4 NO 3 (Merck1187), 10g KH 2 PO 4 (Merck 4873), 40g Solcafloc (Dicacel, purchased from Dicalite-Europe-Nord, 9000 Gent, Belgium), 0.75g MgSO 4 .7H 2 O (Merck 5886), 15g...

Embodiment 2

[0208] Example 2: Purification and identification of Dichotomocladium hesseltinei XET

[0209] Dichotomocladium hesseltinei (CBS164.61) was inoculated on 15 PDA agar slants, and cultured at 26° C. for 7 days. The bacterial cells were washed with about 250 ml of sterile distilled water containing 0.1% Tween80, and used to inoculate 80 shake flasks containing medium B (2-3 ml / bottle). The shake flask was cultured at 26° C. with shaking at 200 rpm for 5 days, and after that time, the culture solution was centrifuged at 4000 rpm for 15 minutes.

[0210] Purify the supernatant containing xyloglucan endotransglycosylase (XET) as follows:

[0211]A filter aid was added to the culture solution filtered through the filter cloth, and the solution was further filtered with a Chua depth filter disc to obtain a clear solution. The pH of the filtrate was adjusted to pH 8.0, and the filtrate was diluted with deionized water to achieve the same conductivity as 20 mM Tris / HCl (pH 8.0).

[0...

Embodiment 3

[0217] Example 3: Purification and identification of Tiarosporella phaseolina XET

[0218] Tiarosporella phaseolina (CBS446.97) was inoculated on 15 PDA agar slants and cultured at 26°C for 7 days. The slant was washed with approximately 250 ml sterile distilled water containing 0.1% Tween80 and used to inoculate 80 shake flasks containing medium B (2-3 ml / flask). The shake flask was cultured at 26° C. with shaking at 200 rpm for 7 days, and after the time was up, the culture solution was centrifuged at 4000 rpm for 15 minutes.

[0219] Purify the supernatant containing xyloglucan endotransglycosylase (XET) as follows:

[0220] A filter aid was added to the culture solution filtered through the filter cloth, and the solution was further filtered with a Chua depth filter disc to obtain a clear solution. The filtrate was concentrated by ultrafiltration on a polyethersulfone membrane with a molecular weight cut-off of 3 Kda, followed by dialysis against distilled water to reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com