Carbon system aluminium spinel air permeable brick

A technology of aluminum spinel and breathable brick, which is applied in the field of iron and steel smelting, can solve problems such as airway blockage, and achieve the effects of reducing infiltration, good slag resistance and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

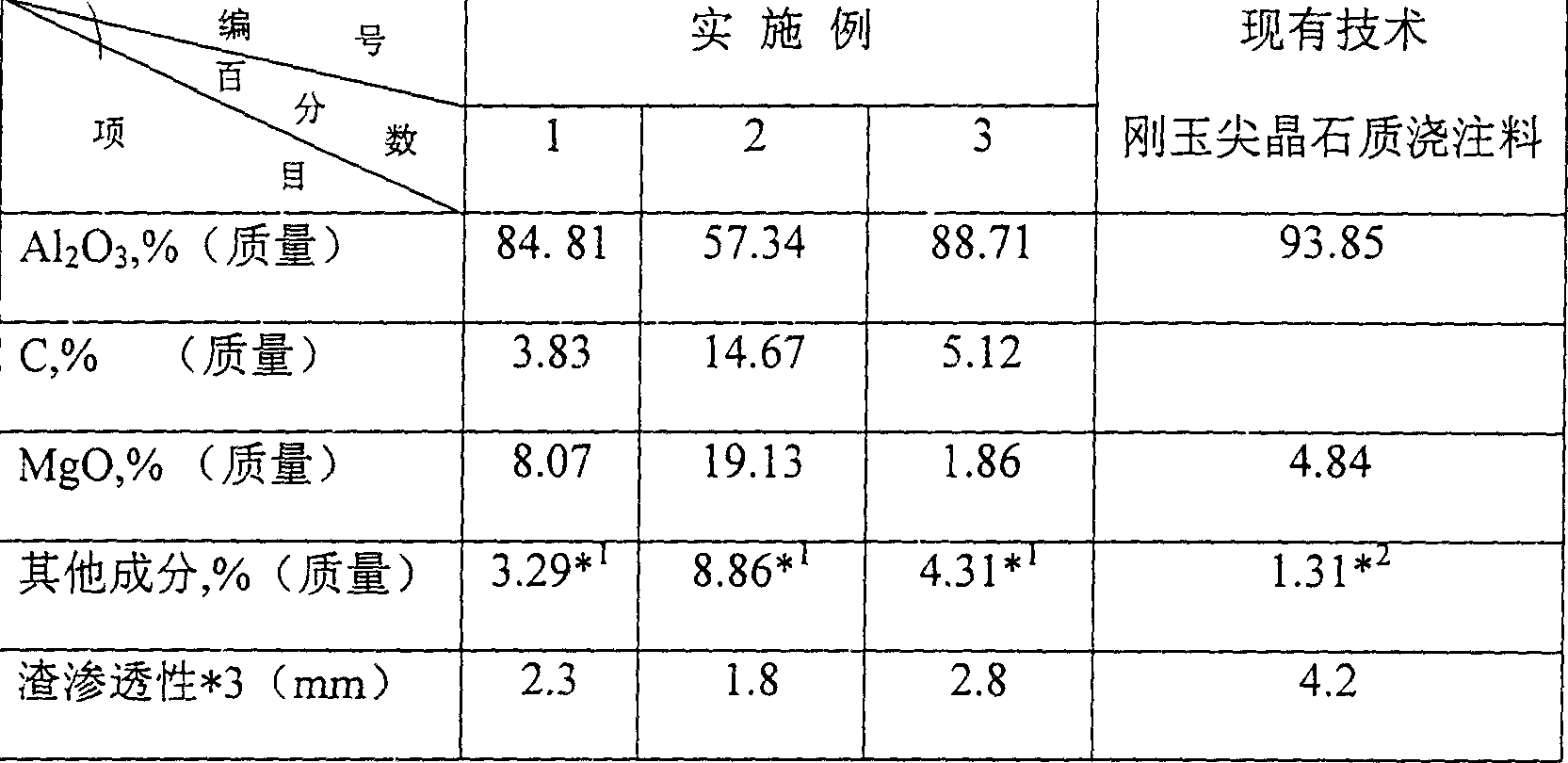

[0012] In order to illustrate this patent in detail, an example is given to illustrate. Specific examples are as follows:

[0013]

[0014] Marked in the table: the symbol *1 is SiC, SiO 2 , Fe 2 O 3 Sum. Symbol *2 is SiO 2 , CaO, Fe 2 O 3 The sum; 5% of pure aluminate cement 75 was added to the sample, and 20% of MA76 (Al 2 O 3 76% sintered magnesia-aluminum spinel). *3 is the result of the slag leaching experiment at 1600℃×6h, in which the steel slag composition (mass percentage, %) is: CaO: 51.64, SiO 2 : 25.9, Al 2 O 3 : 10.62, Fe 2 O 3 : 2.67, MgO: 5.74.

[0015] For breathable bricks, one of the main factors affecting its service life is the resistance to slag penetration. If the slag penetrates deeply, the infiltrated slag will degenerate the material and form a metamorphic layer, which will block the air passage and must be treated by "burning oxygen", which will lead to excessive erosion. If the slag penetration depth is shallow, less airway blockag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com