Technical method for producing P type zeolite utilized in bath by using alkali solution to activate bentonite under high temperature and high pressure

An alkaline solution activation, high temperature and high pressure technology, applied in chemical instruments and methods, inorganic/elemental cleaning compositions, inorganic chemistry, etc., can solve the problems of long activation time, high energy consumption, complex process flow, etc., and improve the deep processing technology. , the effect of improving resource utilization and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

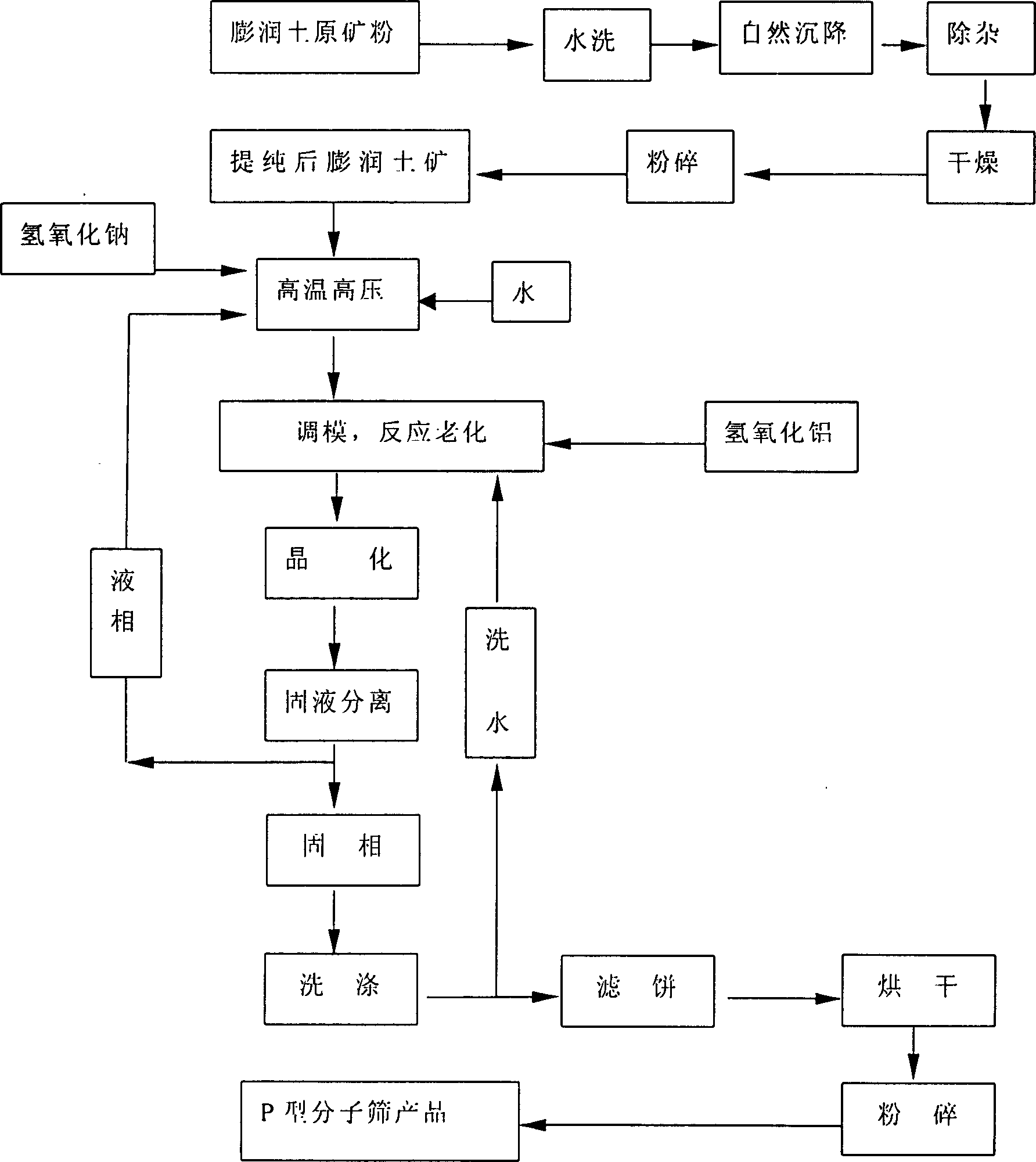

[0018] The process steps of activating bentonite with high-temperature and high-pressure alkali solution to produce P-type zeolite for washing are as follows:

[0019] 1. Purification: The above-mentioned bentonite mineral powder is prepared into a dilute slurry, which is naturally settled to remove the impurities in the lower layer, dried, and then crushed until the particle size is less than 180 mesh, that is, the purified bentonite mineral powder is obtained;

[0020] 2. Activation: After mixing 40g of purified bentonite mineral powder with 40g of caustic soda (sodium hydroxide) and 180ml of water, react in an autoclave at 100°C for 1 hour to obtain the activated feed solution;

[0021] 3. Mold adjustment-reaction aging: Add aluminum hydroxide to the activated material liquid to adjust Al 2 o 3 : SiO 2 :Na 2 O:H 2 The molar ratio of O is 1: 2: 3: 180, aged at a temperature of 45° C. for 8 hours to obtain the raw material liquid of P-type zeolite for washing;

[0022] 4...

Embodiment 2

[0026] The process steps of activating bentonite with high-temperature and high-pressure alkali solution to produce P-type zeolite for washing are as follows:

[0027] 1. Purification: The above-mentioned bentonite mineral powder is prepared into a dilute slurry, which is naturally settled to remove the impurities in the lower layer, then dried, and then crushed to a particle size of less than 180 mesh to obtain the purified bentonite mineral powder;

[0028] 2. Activation: After mixing 40g of purified bentonite mineral powder with 44g of caustic soda (sodium hydroxide) and 185ml of water, react in an autoclave at 120°C for 6 hours to obtain the activated feed solution;

[0029] 3. Mold adjustment-reaction aging: Add aluminum hydroxide to the activated material liquid to adjust Al 2 o 3 : SiO 2 :Na 2 O:H 2 The molar ratio of O is 1: 2.1: 3: 200, aged at a temperature of 40° C. for 5 hours to obtain the raw material liquid of P-type zeolite for washing;

[0030] 4. Crystal...

Embodiment 3

[0034] The process steps of activating bentonite with high-temperature and high-pressure alkali solution to produce P-type zeolite for washing are as follows:

[0035] 1. Purification: The above-mentioned bentonite mineral powder is prepared into a dilute slurry, which is naturally settled to remove the impurities in the lower layer, dried, and then crushed until the particle size is less than 180 mesh, that is, the purified bentonite mineral powder is obtained;

[0036] 2. Activation: After mixing 40g of purified bentonite mineral powder with 50g of caustic soda (sodium hydroxide) and 170ml of water, react in an autoclave at 180°C for 3 hours to obtain the activated feed solution;

[0037] 3. Mold adjustment-reaction aging: Add aluminum hydroxide to the activated material liquid to adjust Al 2 o 3 : SiO 2 :Na 2 O:H 2 The molar ratio of O is 1: 2.3: 3.2: 220, aged at a temperature of 40° C. for 8 hours to obtain the raw material liquid of P-type zeolite for washing;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com