A kind of walnut selection processing technology

A processing technology, walnut technology, applied in the field of walnut selection processing technology, can solve the problems of inability to process high-quality high value-added products, inability to process, and inability to guarantee the quality of walnut kernels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

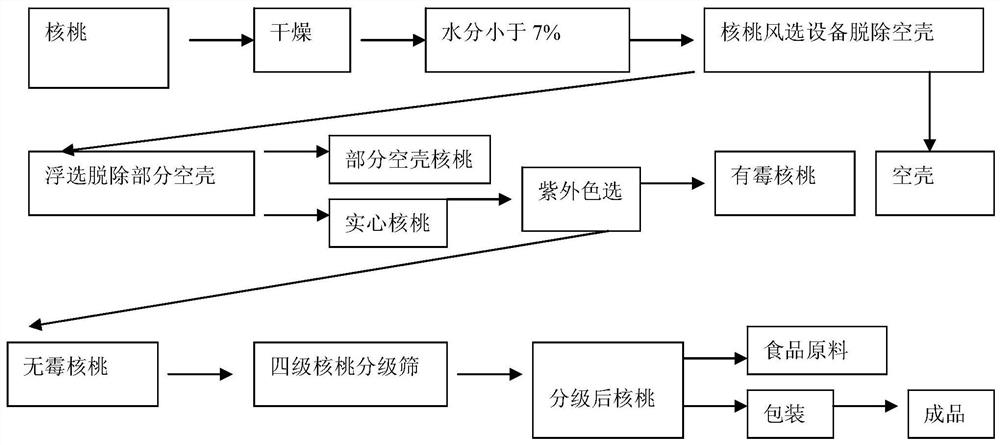

Image

Examples

Embodiment 1

[0020] Embodiment 1: After drying, walnuts with a moisture content of 6% after testing are put into the walnut winnowing equipment, the air volume of the blower is adjusted, the walnuts fall nearly vertically, and the empty shells are blown out close to the horizontal, so as to basically completely remove the empty shells. Remove the shelled walnuts and enter the clear water flotation equipment to separate some hollow walnuts; the upper layer of the flotation machine produces some empty shelled walnuts, and the lower layer produces solid walnuts; the separated walnuts are quickly air-dried by an air dryer to remove surface moisture , the walnut after removing the surface moisture, the moisture content is 6.8% after testing. Part of the hollow walnuts are removed, put into the ultraviolet color sorter, and after removing the moldy walnuts, enter the next process. Remove the moldy walnuts and put them into the rotary walnut grading and separation equipment. The inclination of th...

Embodiment 2

[0021] Embodiment 2: After drying, walnuts with a moisture content of 4% after testing are entered into the walnut winnowing equipment, the air volume of the blower is adjusted, the walnuts fall nearly vertically, and the empty shells are blown out close to the horizontal, so as to basically completely remove the empty shells. Remove the shelled walnuts and enter the clear water flotation equipment to separate some hollow walnuts; the upper layer of the flotation machine produces some empty shelled walnuts, and the lower layer produces solid walnuts; the separated walnuts are quickly air-dried by an air dryer to remove surface moisture , the walnut after removing the surface moisture, the moisture content is 5.6% after testing. Part of the hollow walnuts are removed, put into the ultraviolet color sorter, and after removing the moldy walnuts, enter the next process. Remove the moldy walnuts and put them into the rotary walnut grading and separation equipment. The inclination o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com