A kind of processing technology of Camellia oleifera seed selection

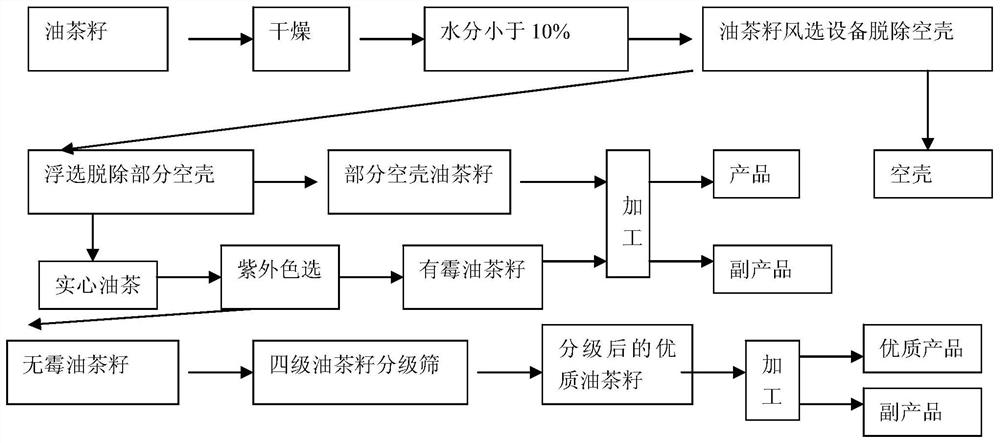

A processing technology, the technology of camellia oleifera seed, which is applied in the field of selected processing technology of camellia oleifera seed, can solve the problems of reducing economic benefits, waste of high-quality products, and inability to differentiate processing, etc., and achieves promotion value, deep processing technology improvement, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020]Example 1: After the drying, the detected water is divided into 9% oil tea seed, enter the oil tea seed product, mediate the air air supply, the oil tea seed is close to vertical, the empty shell is close to the horizontal blowing to basically remove the empty shell. The oil tea seeds that remove the empty shell, enter the specific gravity sorting equipment, separate some hollow oil tea seeds, while removing the proportion of impurities. Removal of partially hollow oil tea seeds, enters the ultraviolet colors, removes the mold of molds, and enters the next process.

[0021]Removal of mildew oil tea seeds, into the rotation oil tea seed classification equipment, the equipment is inclined 75 °, graded the oil tea seeds into four level; the upper sieve plate is 30, the intermediate sieve plate aperture 20-30, lower screen plate aperture 10-20; the upper layer of oil is more than 30 oil tea seeds, and the intermediate sieve plate is 20-30 oil tea seeds, the lower screen plate is 10-2...

Embodiment 2

[0022]Example 2: After the drying, the detection of water is divided into 8% oil tea seeds, enter the oil tea seed product, mediate the air air, and the oil tea seed is close to vertical, the empty shell is close to the horizontal blowing to basically remove the empty shell. The oil tea seeds that remove the empty shell, enter the specific gravity sorting equipment, separate some hollow oil tea seeds, while removing the proportion of impurities. Removal of partially hollow oil tea seeds, enters the ultraviolet colors, removes the mold of molds, and enters the next process.

[0023]Removal of mildew oil tea seeds, into the rotation oil tea seed classification equipment, the equipment is inclined 75 °, graded the oil tea seeds into four level; the upper sieve plate is 30, the intermediate sieve plate aperture 20-30, lower screen plate aperture 10-20; the upper layer of oil is more than 30 oil tea seeds, and the intermediate sieve plate is 20-30 oil tea seeds, the lower screen plate is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com