Weld repair of directionally solidified articles

A technology of directional crystallization and parts, applied in the direction of welding equipment, welding medium, welding equipment, etc., can solve problems such as insufficient repair, low toughness, uneven microstructure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

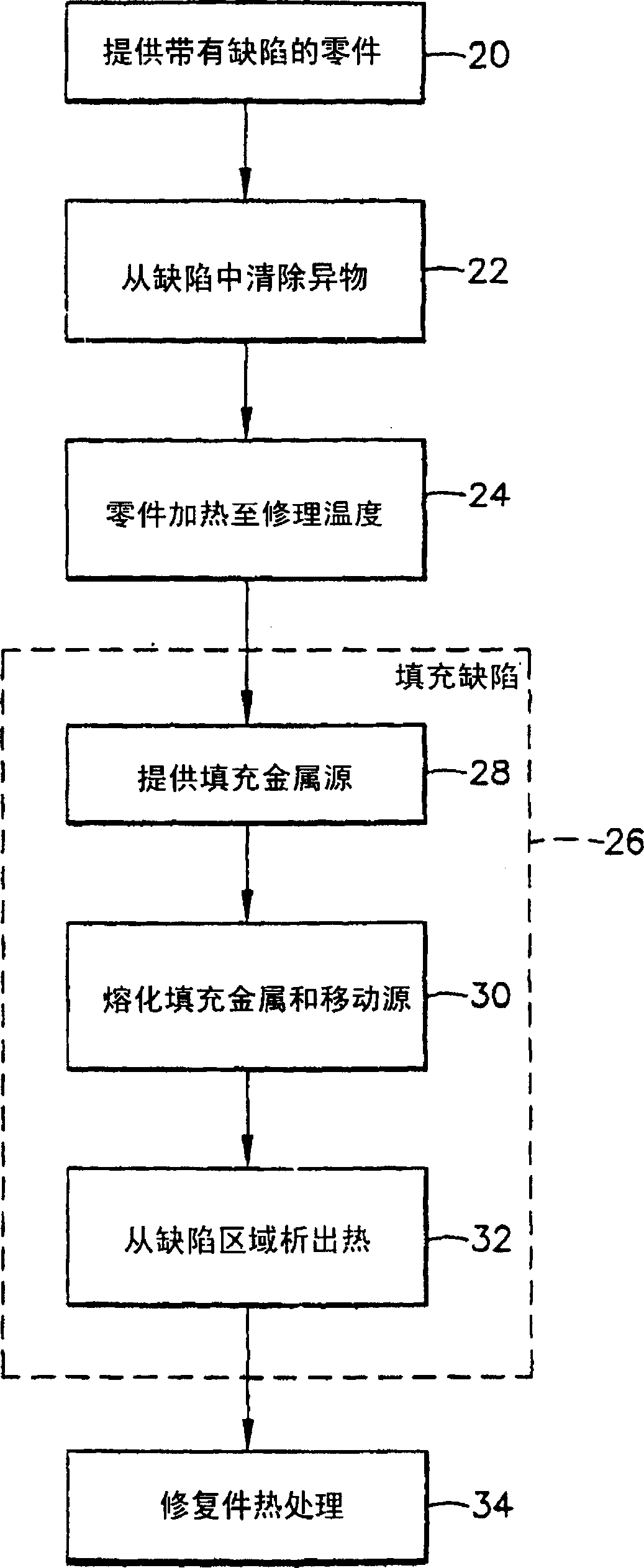

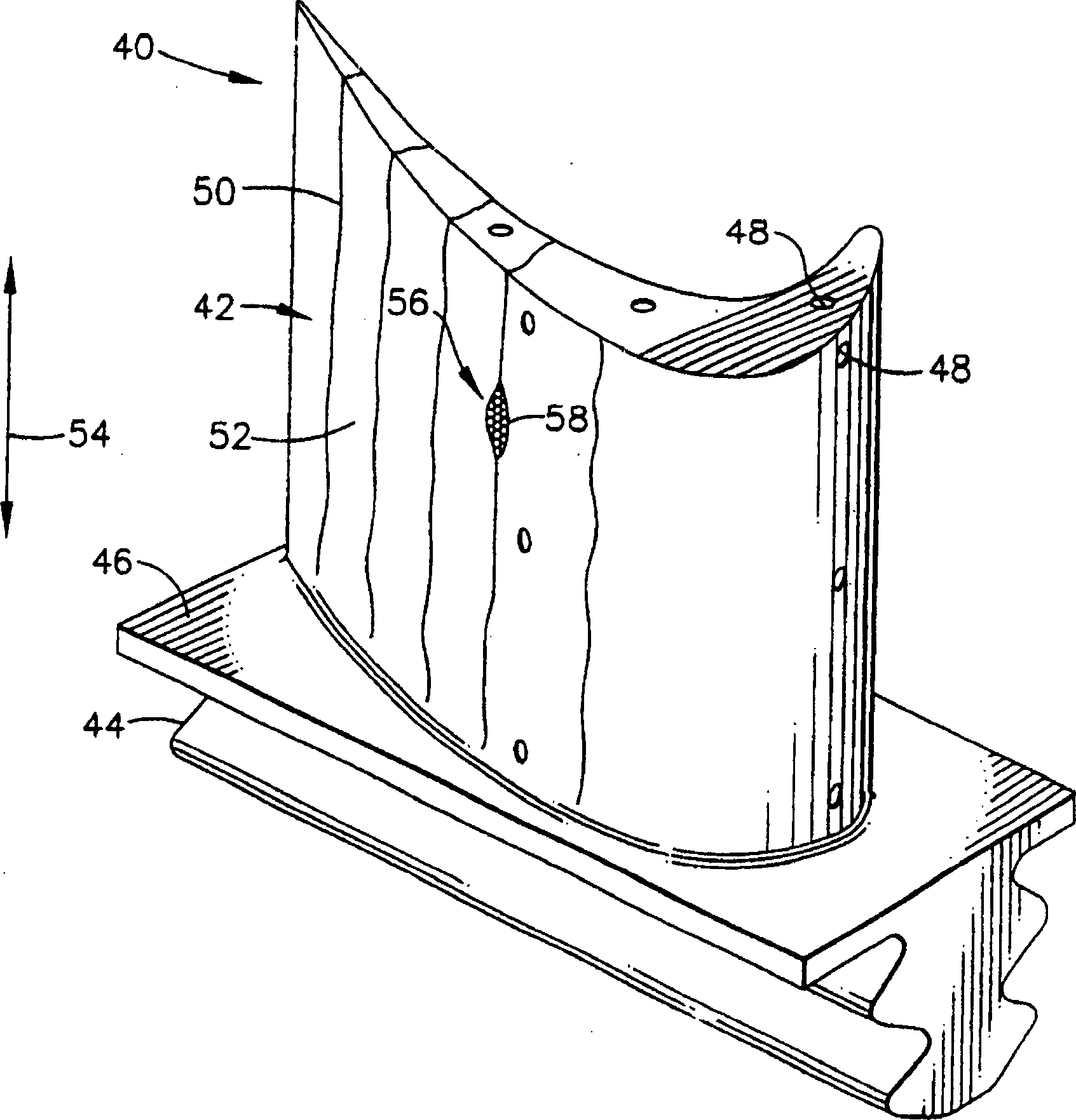

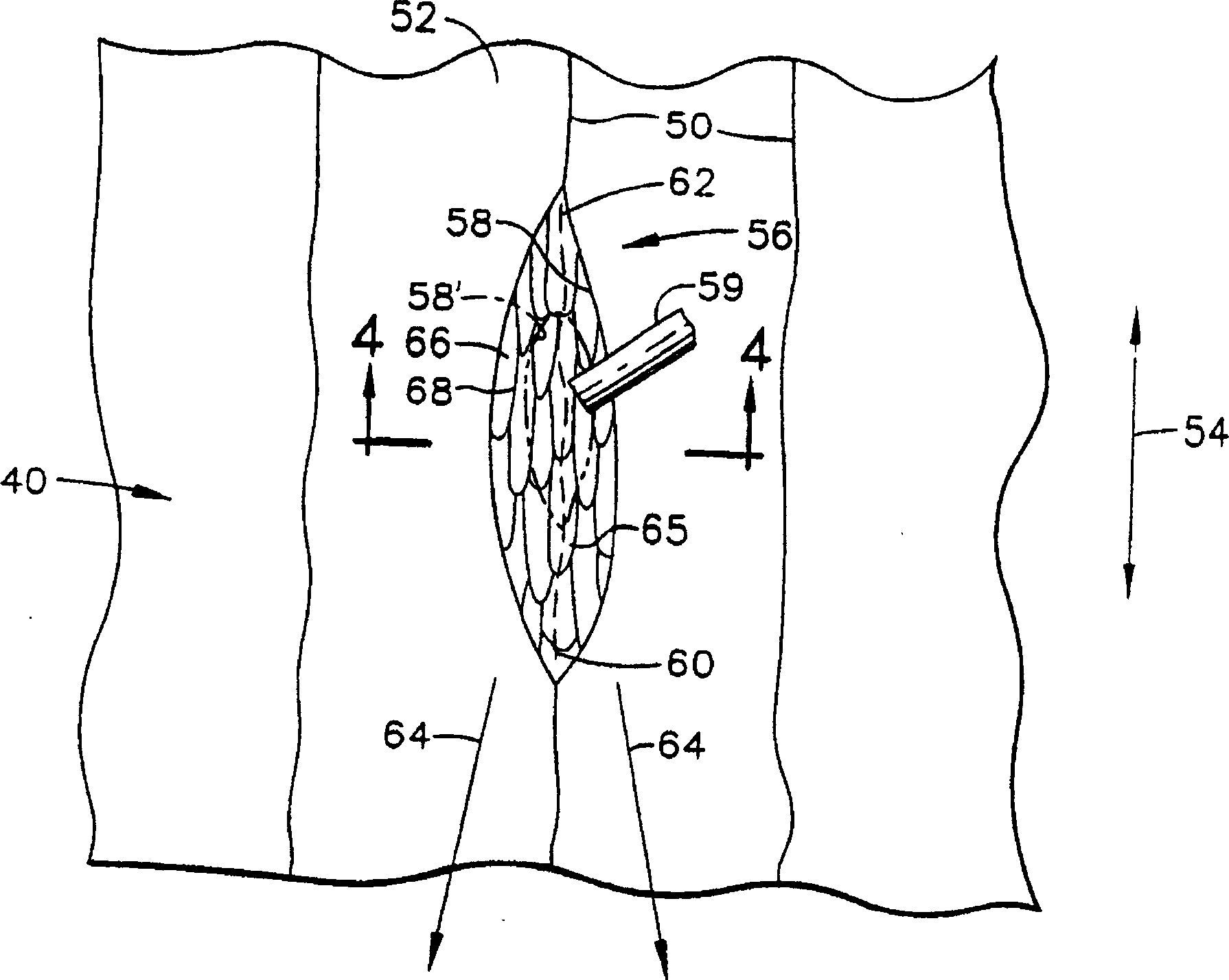

[0020] figure 1 It is a block flow diagram of the preferred method for implementing the present invention. Supplied with a directional crystal part, No. 20. figure 2 Such an orientated crystallization member 40 is shown, in this case a turbine blade of a gas turbine engine. The turbine blade 40 includes an airfoil 42 . When the turbine blade is operating in a gas turbine engine, the hot exhaust flow is impinging on the airfoil 42 . The turbine blade 40 is mounted to a turbine disk (not shown) with a dovetail 44 extending downwardly from the airfoil 42 and engaging a slot in the turbine disk. A lip 46 extends longitudinally outwardly from the region where the airfoil 42 and the dovetail 44 connect. There are internal passages which may run through the interior of the airfoil 42 , terminating in holes 48 in the face of the airfoil 42 . All or a portion of the part 40 may be covered with a protective coating. The invention is applicable to turbine blades, which is the pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com