Synthetic leather producing method for four-way stretch elastic

A manufacturing method and technology for synthetic leather, applied in the field of synthetic leather, can solve the problems of cumbersome manufacturing process, waste of time, and the inability of synthetic leather to achieve lightness, thinness and four-way elasticity, and achieve the effect of high product variability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

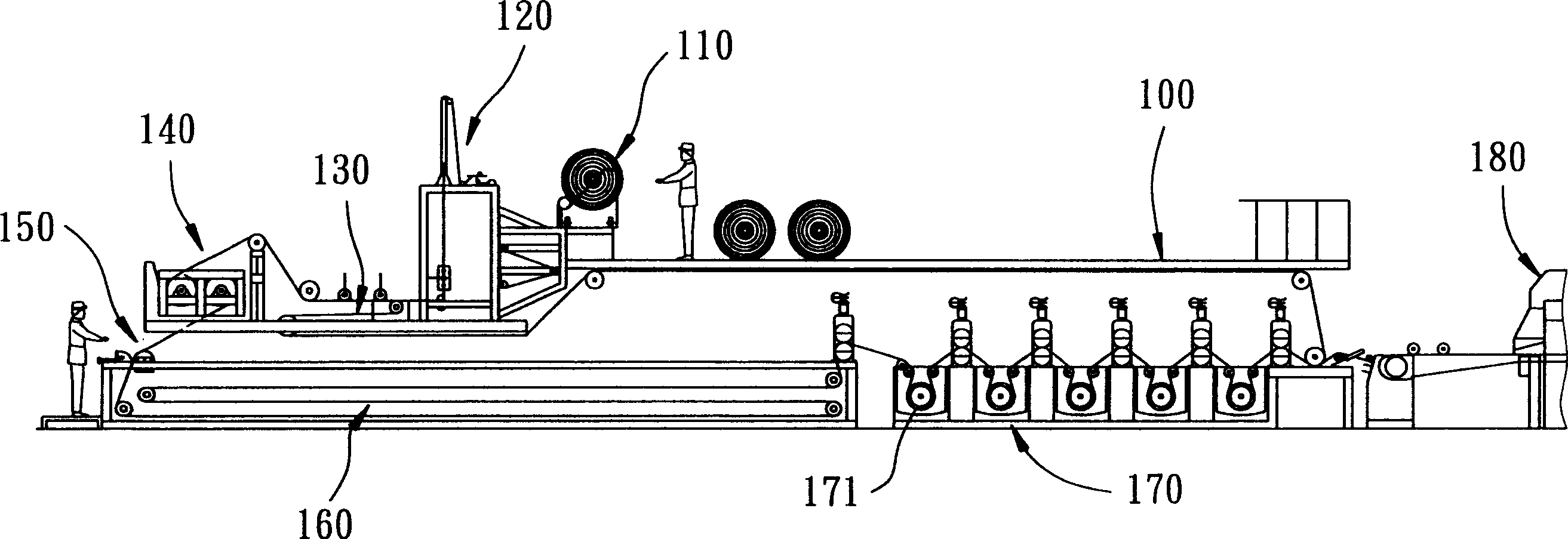

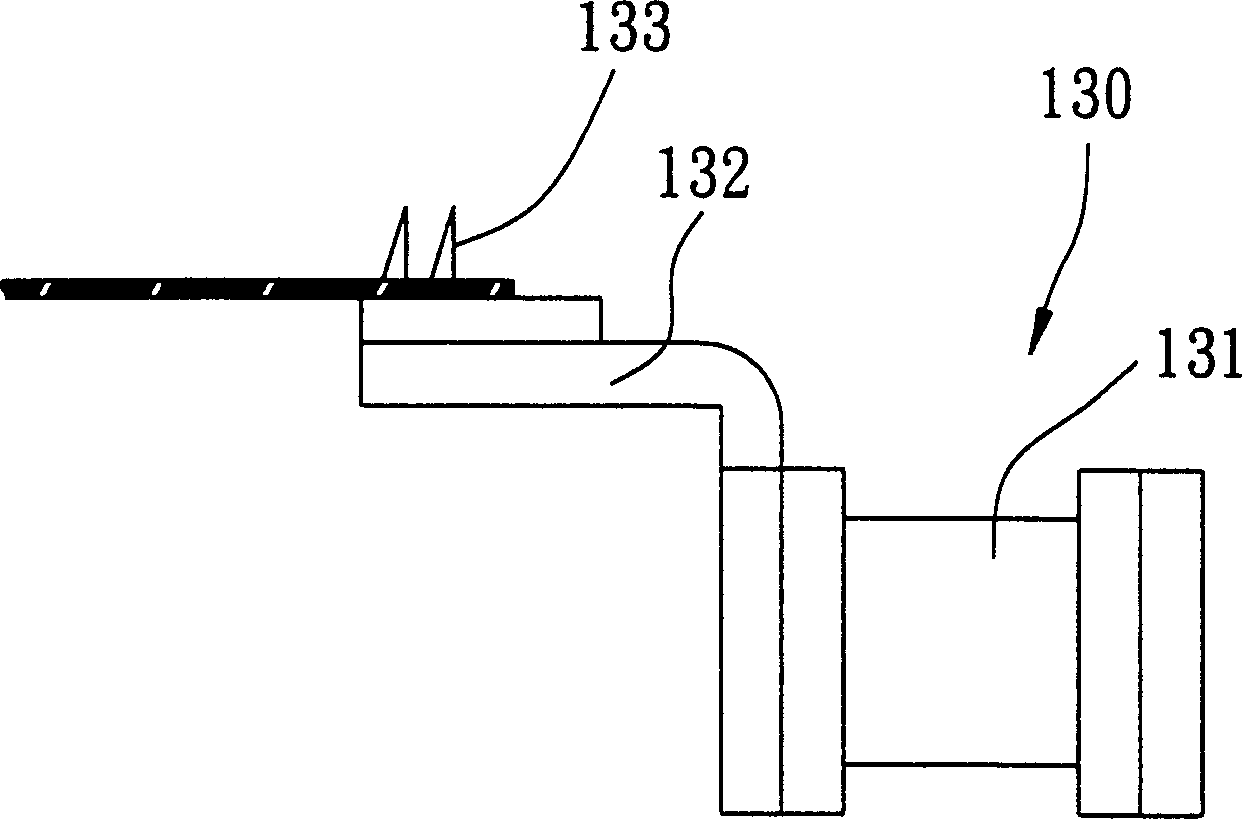

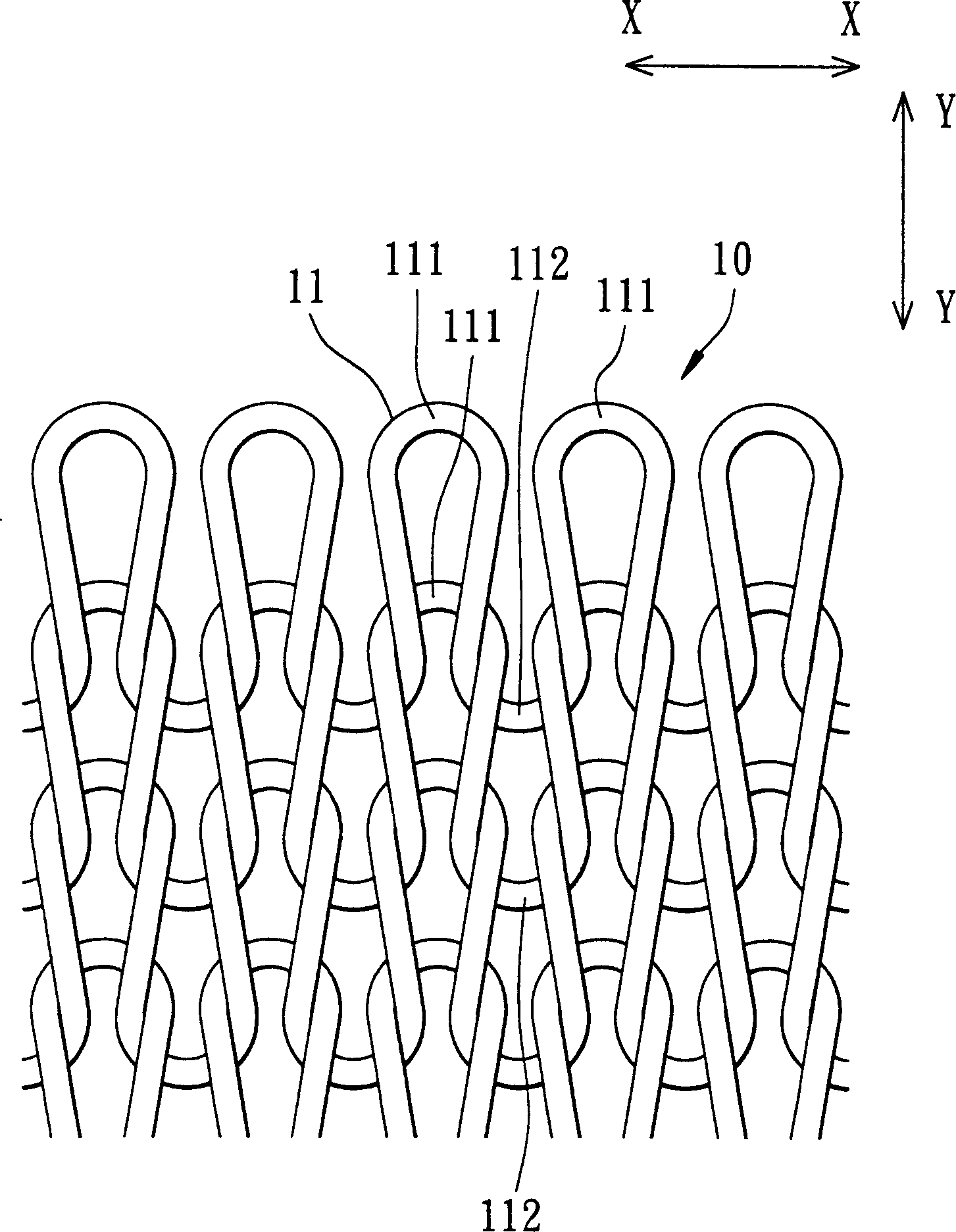

[0025] like figure 1 , figure 2 As shown, a preferred embodiment of the synthetic leather manufacturing method with four-way stretch elasticity of the present invention is to cooperate with a manufacturing equipment to carry out a predetermined manufacturing process. The roll-out device 110 at the end, a spreading device 120 located on one side of the rolling-out device 110, a conveyor chain unit 130 that is located on one side of the spreading device 120 and can run in a certain direction, and a conveyor chain unit 130 adjacent to the spreading device 120. Cloth device 120 and an ironing device 140 that can pass through the conveying chain unit 130, a coating device 150 located downstream of the ironing device 140 corresponding to the conveying direction of the conveying chain unit 130, a corresponding conveying chain unit 130 conveying direction and located The coagulation tank 160 downstream of the coating device 150 , a water washing device 170 downstream of the coagulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com