Digestion tolerant starch and its preparation method and uses

A technology of anti-digestible starch and starch, which is applied in the direction of fermentation, etc., can solve the problems that have not been reported, and achieve the effects of facilitating industrial production, increasing added value, and controlling the biodegradation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

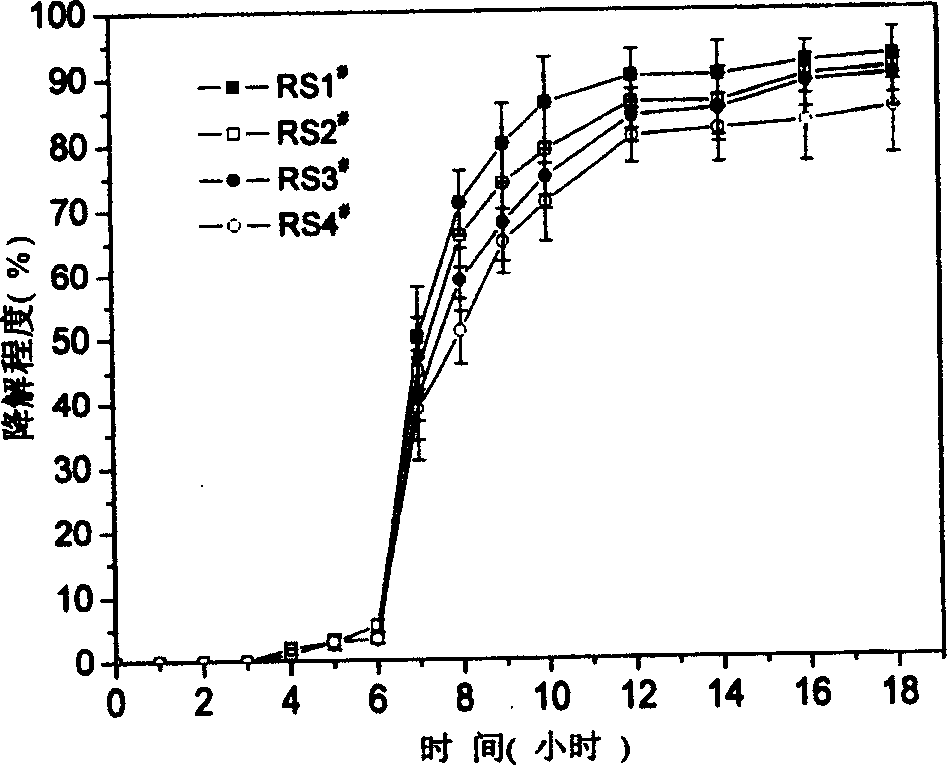

Image

Examples

Embodiment 1

[0027] Add 185 grams of water to 815 grams of cornstarch (moisture content is 14.2%) in the mixer, make the material moisture content reach 30%, fully mix; Heat to 90 ℃ in airtight state, constantly stir and keep 30min, the material After cooling down to room temperature in the mixer, take it out, use 5000U / g starch heat-resistant α-amylase at pH 6.0, temperature 100°C for 0.5h, then use 300U / g starch at pH 4.0, temperature 50°C The glucoamylase was fully enzymatically hydrolyzed for 1h; the enzymolyzed product was centrifuged, washed, filtered, dried, and crushed to obtain resistant starch RS1 # .

Embodiment 2

[0029] Add 26.3 grams of water to 500 grams of high-chain corn starch (moisture content is 15.8%) in the mixer to make the material moisture content reach 20%, fully mix and seal for 24 hours, put into 4520PST high-temperature pressure reaction kettle (PARR company in the United States) During the process, adjust the temperature to 120°C, control the pressure at 0.7MPa, and keep the reaction conditions stable for 2 hours. After the material is cooled to room temperature in the mixer, it is taken out and dried in an electric constant temperature blast drying oven at 50°C to obtain anti-digestion Starch RS2 # .

Embodiment 3

[0031] Add 89.6 grams of water to 600 grams of mung bean starch (moisture content is 16.1%) in mixer, make material moisture content reach 27%, fully mix and seal and place 24h, put into 4520PST high-temperature pressure reaction kettle (U.S. PARR company), Adjust the temperature to 110°C, control the pressure at 1MPa, and keep the reaction conditions stable for 1 hour. After the material is cooled to room temperature in the mixer, take it out, and use 8000U / g starch heat-resistant α-amylase at pH 6.0 and temperature 100°C Under the action of 0.5h, then fully enzymolyzed with 300U / g starch glucoamylase at pH 4.5 and temperature 60°C for 1h; the enzymolyzed product was centrifuged, washed, dried and pulverized in an electric heating constant temperature blast drying oven at 50°C Resistant starch RS3 # .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com