Washing machine

A washing machine and detergent technology, applied in the field of washing machines, can solve the problems of unautomated detergent input method, labor saving, soiling the ground, knocking down, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

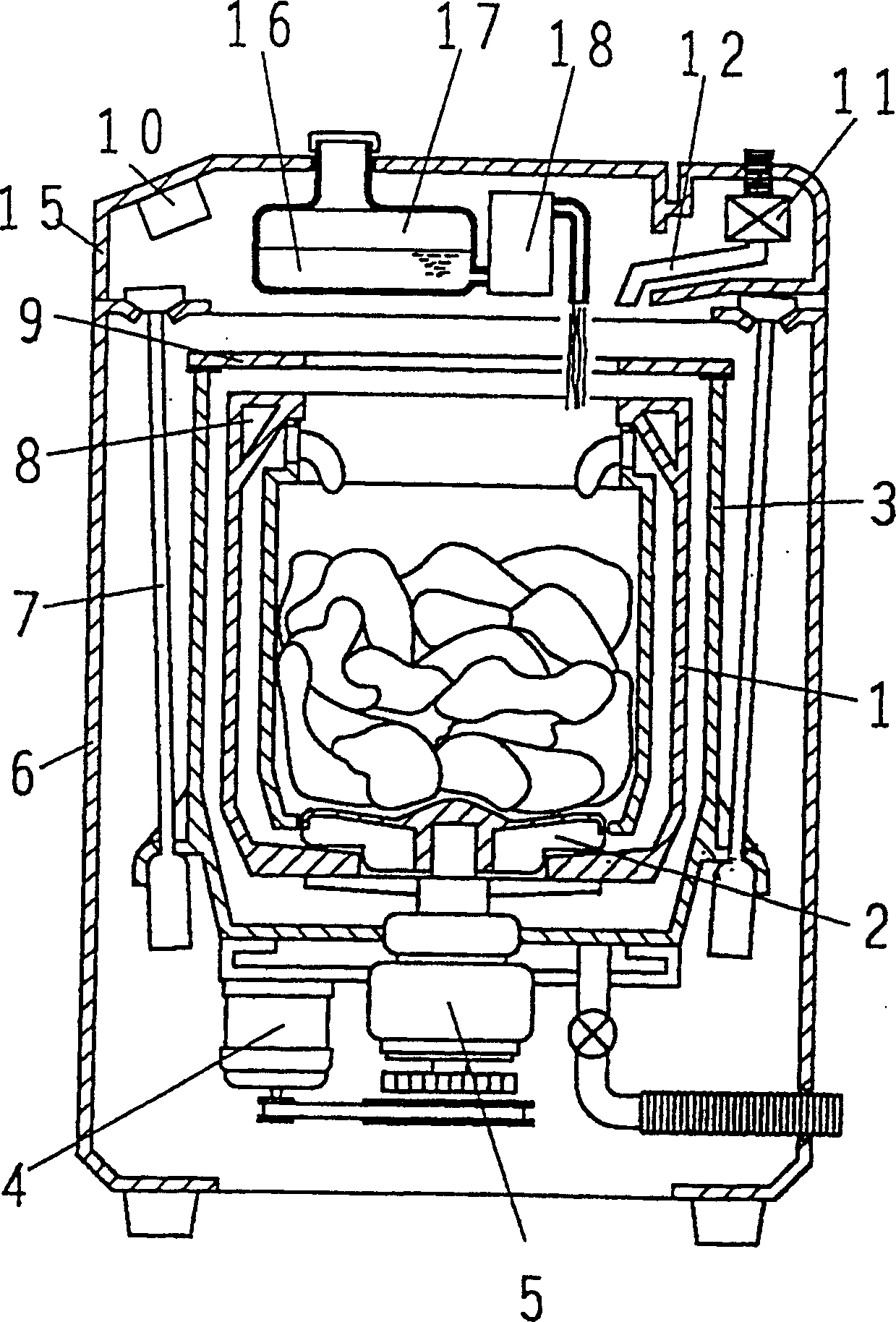

[0043] Such as figure 1 As shown, the housing cover 15 covers the upper part of the housing 6, and is provided with a control device 10, a water supply valve 11, a water supply pipeline 12, and the like. A detergent tank 17 is provided inside the housing 15, and accommodates liquid detergent 16 in an amount capable of at least two washes. Detergent input device 18 is used to inject liquid detergent 16 in detergent box 17 into washing and dehydration tank 1, and is composed of manual pump, automatic pump, liquid (gas) pressure cylinder, etc., and is controlled and operated by control device 10.

[0044] In the above-mentioned structure, the liquid detergent 16 that can be used for at least twice washing is placed in the detergent box 17, and the detergent box 17 is installed in the outer casing 15, and the laundry is dropped into the washing and dehydrating tank 1 When the internal operation is started, the control device 10 drives the detergent input device 18 to inject a pr...

Embodiment 2

[0048] figure 1 The control device 10 shown has a cloth amount judging device (not shown) for judging the amount of laundry (clothes) thrown into the washing and dehydrating tank 1, and according to the result of judging by the cloth amount judging device, that is, according to the amount of laundry According to at least one parameter of the amount of water or the amount of water suitable for the amount of laundry, operate the detergent input device 18, and put the liquid detergent 16 into the washing and dehydrating tank 1. Other structures are the same as the above-mentioned embodiment 1.

[0049] In the above structure, when the laundry is put into the washing and dehydrating tank 1 to start operation, the control device 10 drives the motor 4 to rotate the agitating blade 2, and judges according to the degree of deceleration of the motor 4 in the inertial operation after the power supply to the motor 4 is cut off. The amount of laundry in the washing and dehydrating tank ...

Embodiment 3

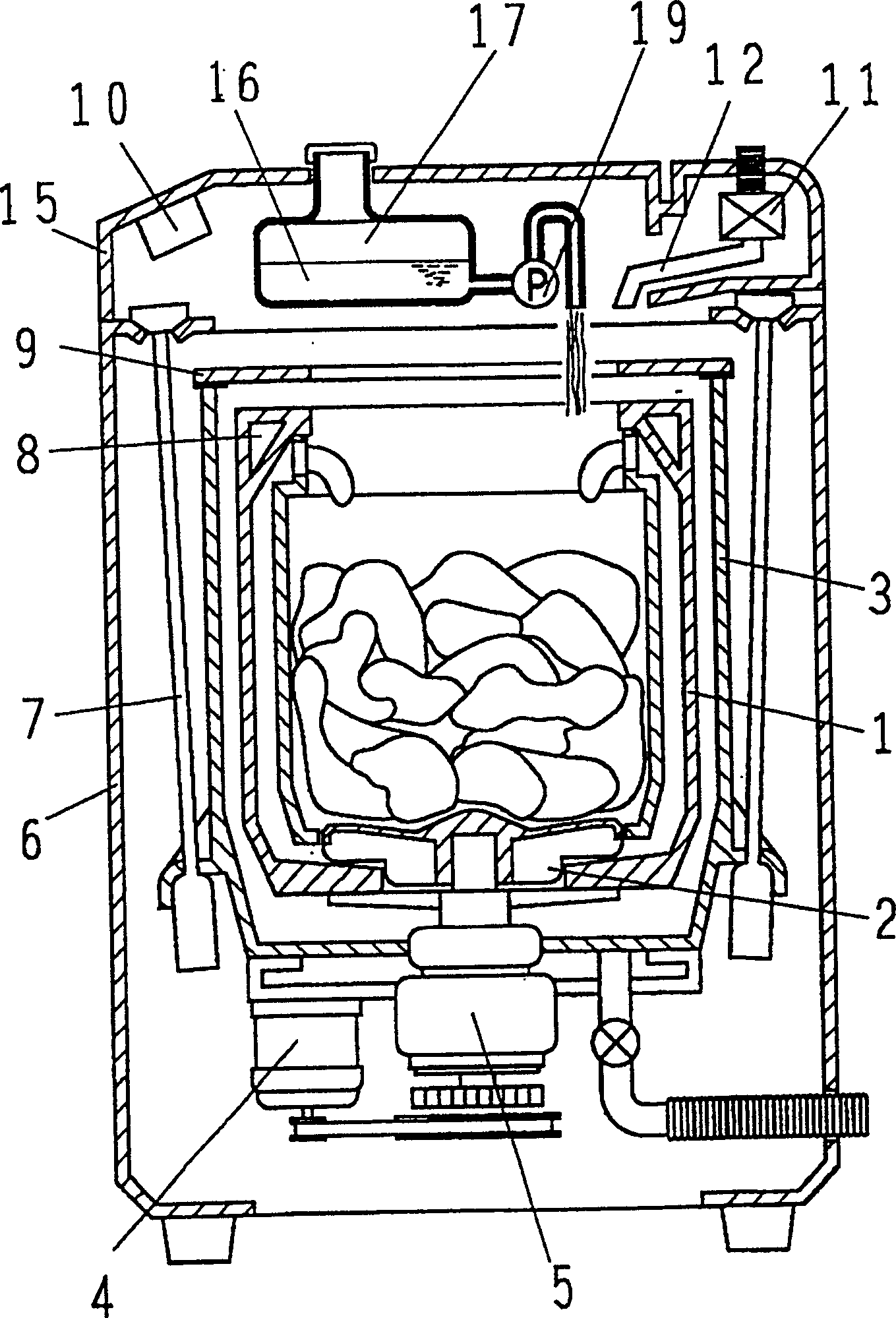

[0052] Such as figure 2 As shown, the pump device 19 constitutes a detergent input device, and is composed of a pump device that directly sucks liquid detergent, such as a centrifugal pump or a gear pump. Other structures are the same as the above-mentioned embodiment 1 or 2.

[0053] In the above structure, when the laundry is put into the washing and dehydrating tank 1 to start operation, the control device 10 drives the motor 4 to rotate the agitating blade 2, and judges according to the degree of deceleration of the motor 4 in the inertial operation after the power supply to the motor 4 is cut off. The amount of laundry in the washing and dehydrating tank 1. Based on the determination result, the pump device 19 is operated, and the liquid detergent 16 is injected into the washing and dehydrating tank 1 in an amount corresponding to the laundry in the washing and dehydrating tank 1 .

[0054] Thereafter, the operation of the motor 4 and the water supply valve 11 is contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com