Process for preparing ecological safety composite iron series high-effective flocculating agent

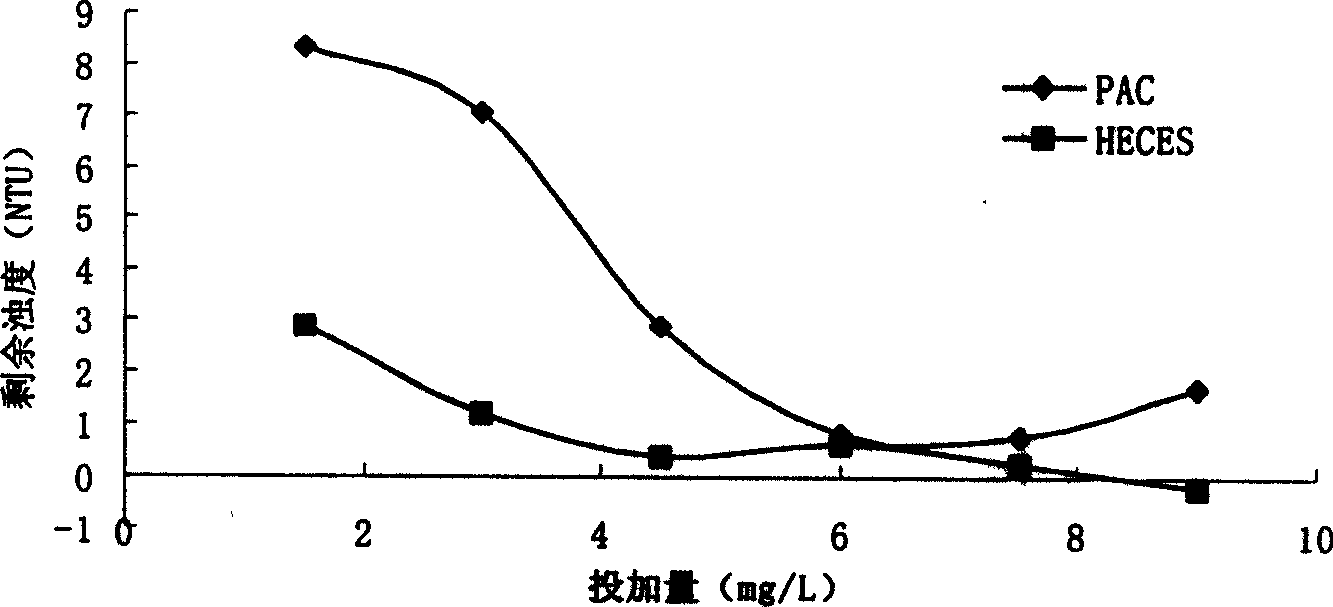

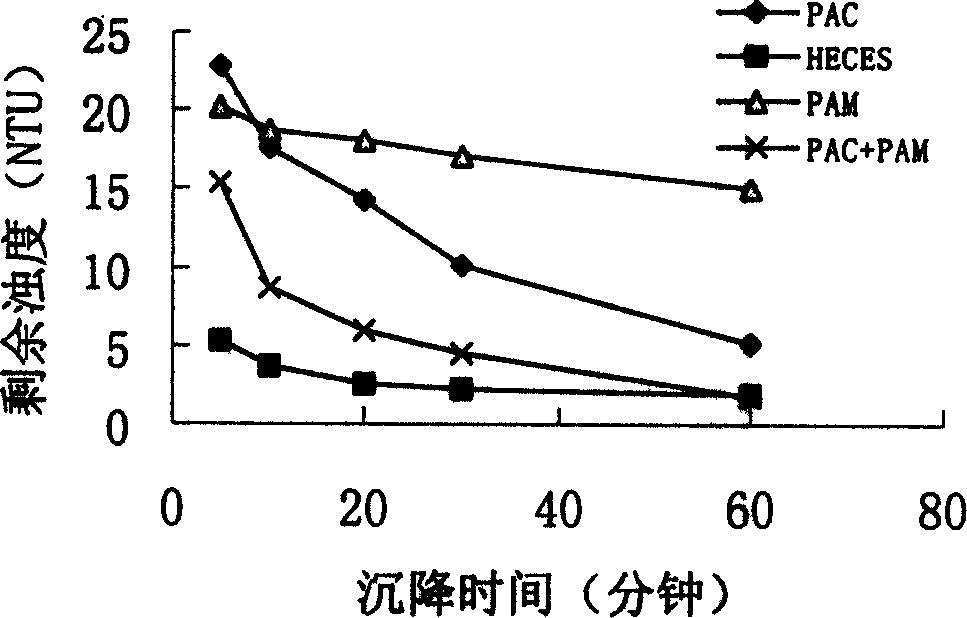

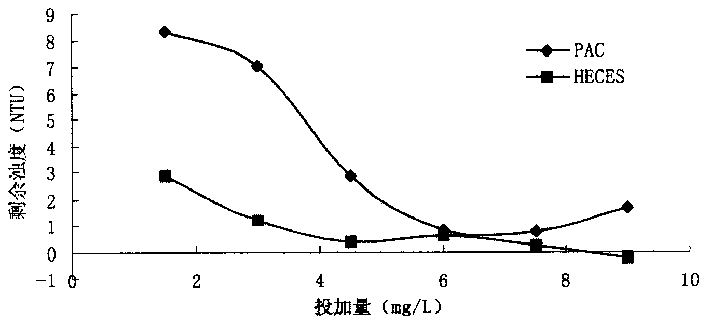

An ecologically safe and complex technology, applied in the field of water treatment, can solve the problems of complex production process of flocculation material, high production cost, ecological insecurity, etc., and achieve good flocculation effect, fast settling speed, and reduced dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present invention takes iron salt, cornstarch, ethanol, sodium hydroxide (NaOH) as raw material; Wherein, iron salt is FeCl 3 , corn starch is the main component, ethanol is used as a reaction solvent, and sodium hydroxide is used for the modification of corn starch; the mass ratio of iron and corn starch in the iron salt is 1:8.

[0037] Its preparation method is as follows: (1) preparation of iron salt: take 1 gram of iron powder according to the mass ratio and use 20% HCl to completely dissolve and then use oxidant (chlorine gas) to form a solution containing ferric iron; (2) modification of starch : Get 3 grams of cornstarch and dissolve completely with 95% ethanol, slowly add 20% NaOH of 6mL in a water bath at 55°C and slowly stir the modified reaction for 1 hour; (3) composite reaction: FeCl 3 Stir and mix the solution with the modified starch, adjust the pH to 1.0 with 0.1N HCl solution, and react in a water bath at 55°C for 3 hours to obtain a reddish-brown ...

Embodiment 2

[0039] The difference from Example 1 is: water (distilled water, tap water) replaces absolute ethanol as the reaction solvent, and its preparation method is: (1) preparation of iron salt: get 1 gram of iron powder by mass ratio and use 10% HCl to After completely dissolving, use oxidizing agent (chlorine, hydrogen peroxide, etc.) Slowly add 6mL of 20% NaOH into a water bath at 55°C and stir slowly for 1 hour for the modification reaction; (3) Composite reaction: Mix the modified starch and iron salt thoroughly, adjust the pH to 1.0 with 0.1N HCl solution, and add FeCl 3 The solution was stirred and mixed with the modified starch and reacted in a water bath at 55°C for 3 hours to obtain a reddish-brown emulsion, which is the product flocculant.

Embodiment 3

[0041]The difference from Example 1 is that the mass ratio of iron to cornstarch in the iron salt is 1:1. Its preparation method is: (1) preparation of iron salt: take 1 gram of iron powder by mass ratio and use 20% HCl to completely dissolve, and then use oxidant (chlorine, hydrogen peroxide, etc.) to form a solution containing ferric iron; ( 2) Modification of starch: take 1 gram of corn starch and dissolve it completely with absolute ethanol, slowly add 6 mL of 20% NaOH in a water bath at 55°C and slowly stir for modification reaction for 1 hour; (3) Compound reaction: FeCl 3 Stir and mix the solution with the modified starch, adjust the pH to 1.5 with 1N HCl solution, and react in a 55°C water bath for 3 hours to obtain a reddish-brown emulsion, which is the product flocculant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com