Gas shielded welding device

A technology of shielding gas and welding device, which is applied in the directions of tin feeding device, welding equipment, welding equipment, etc., can solve the problem that the oxygen concentration of the inert shielding gas cannot be fully reduced, and achieve the effect of improving the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Embodiments of the present invention will be described in detail below with reference to the drawings.

[0062] (1) Embodiment of the airflow control device

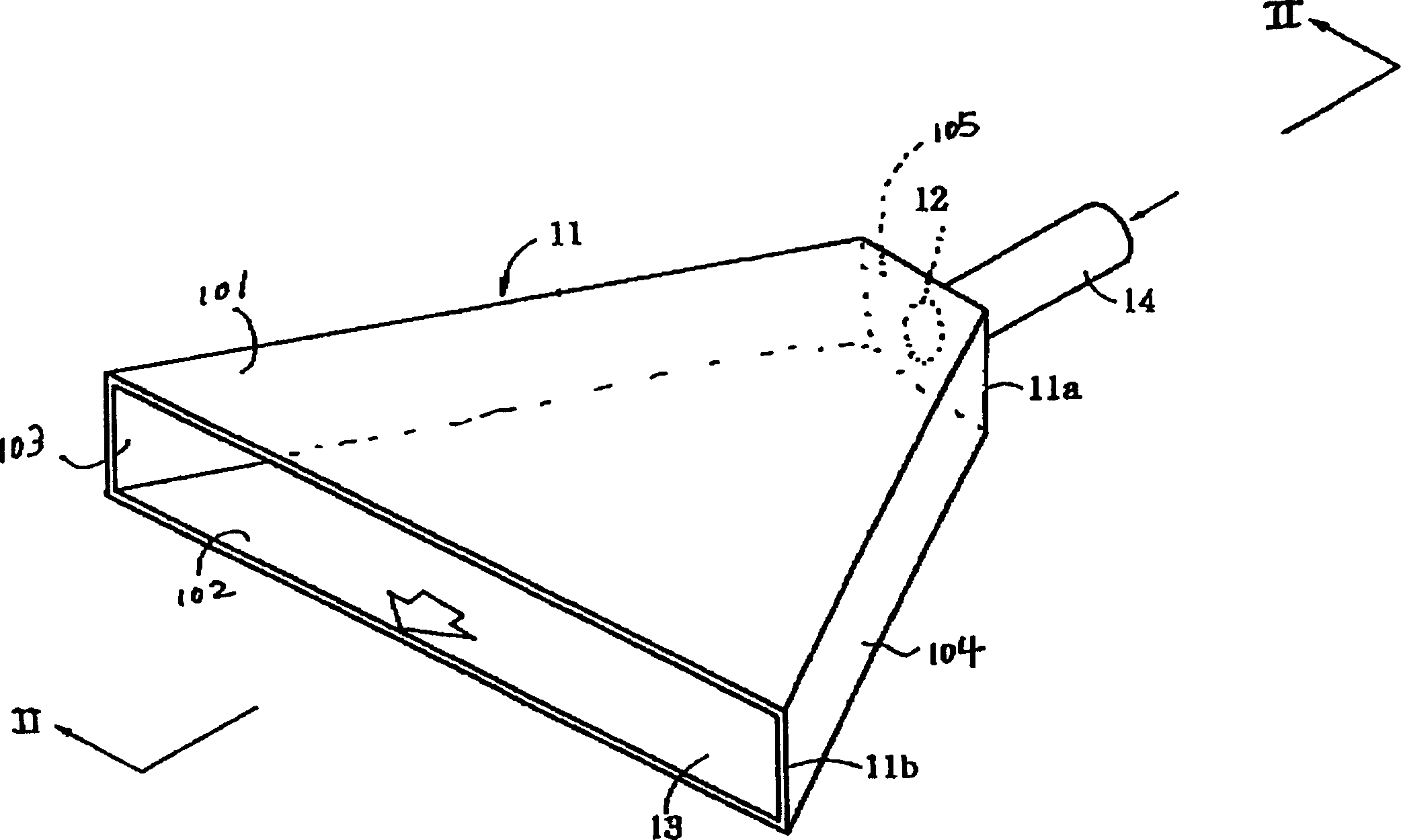

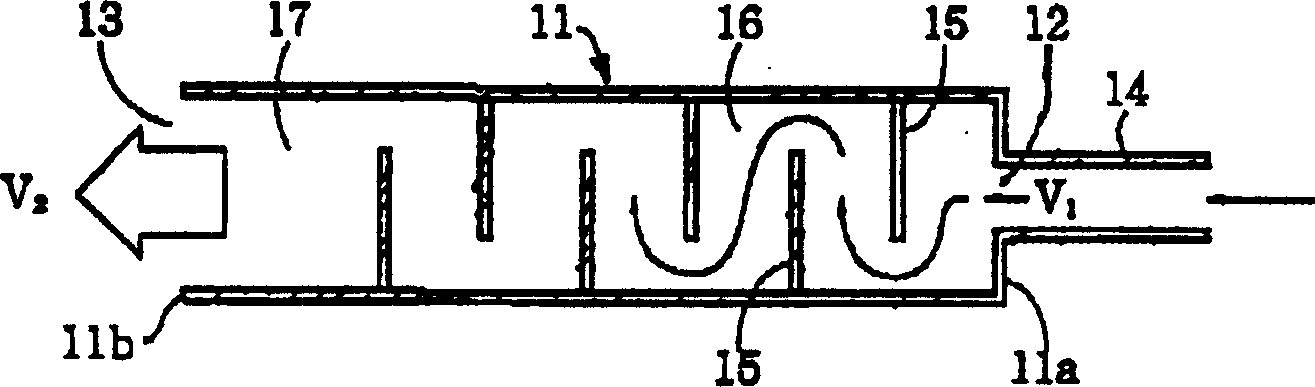

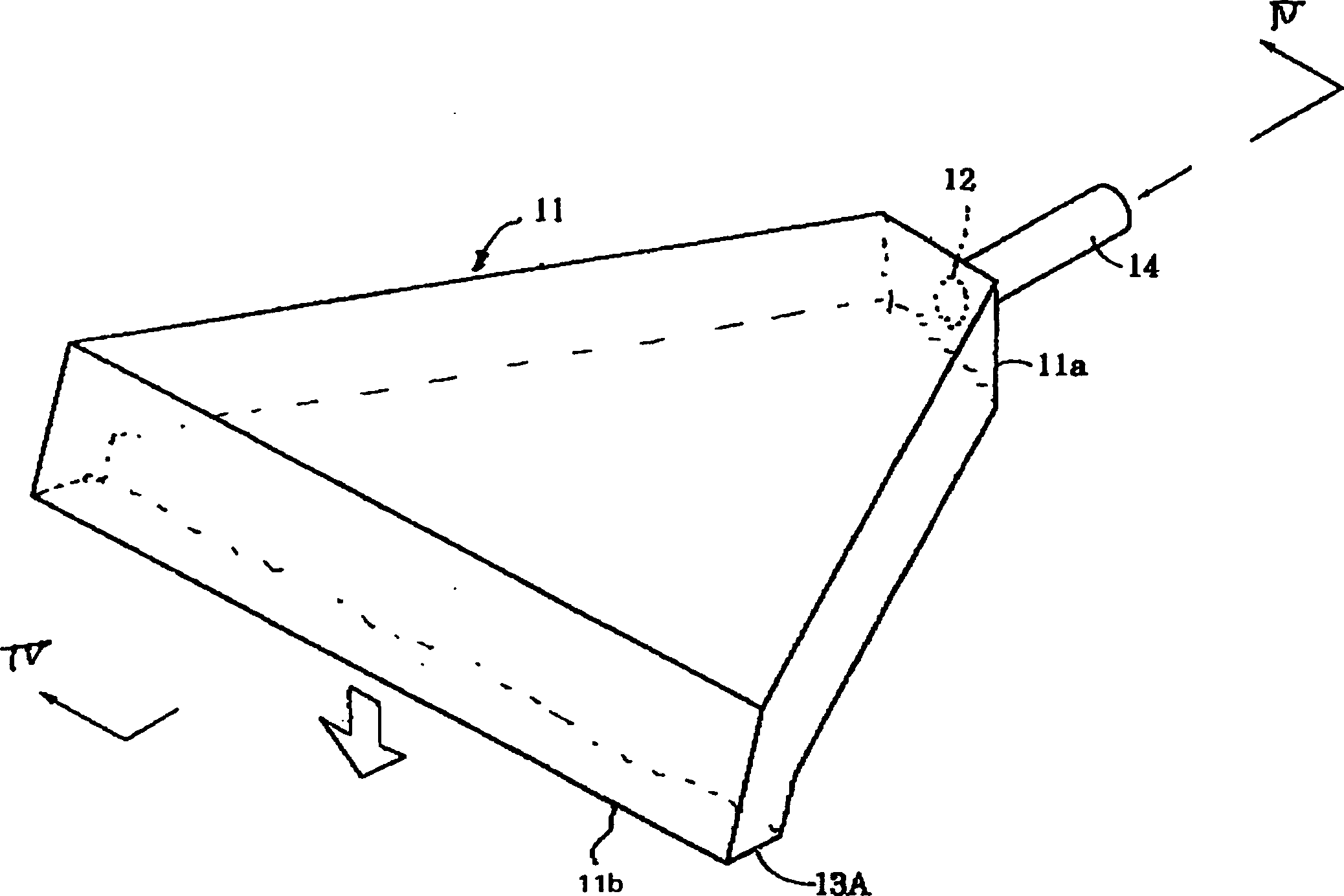

[0063] figure 1 It is an oblique view of the overall view of the first embodiment of the air flow control device of the present invention; image 3 It is a perspective view of the overall view of the second embodiment of the air flow control device of the present invention. in addition, figure 2 is along figure 1 The side sectional view of the II-II line; Figure 4 is along image 3 Side sectional view of line IV-IV. That is, in these figures, the air supply port is formed on the converging end portion 11a of one side of the radial air supply port frame 11 composed of a pair of upper and lower walls 101, 102, a pair of side walls 103, 104, and a rear wall 105. 12, and connect the air supply pipe 14, supply N 2 (nitrogen) and other inert gases. On the upper and lower walls 101 , 102 of the air inlet fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com