Production technology of real-wood handicraft composite reinforced board

A production process and wood process technology, applied in the field of interior building decoration materials, can solve the problems of unreal surface, high production cost, poor wear resistance, etc., and achieve the effects of not easy to violent, low cost and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] The production process of the solid wood process composite reinforced board of the present invention is completed according to the following steps: the production of thin wood: select precious famous wood as: black walnut, Sapele, Thai pomelo, rosewood, sandalwood, rosewood, cherry wood, Southwest Birch, ash, ash, yellow pineapple, sawed and cut into standard timber, and planed into quarter-cut and rotary-cut, can be used for butt joint, mosaic, mountain grain and straight grain on the veneer; the temperature is above 50 ℃ After soaking in hot water, choose wood blocks with different semi-rotation radius, rotation, diameter or color difference for process matching; glue them with water-resistant high-strength adhesive, and then press them into shape by cold press and pressurizer. Cut into 20mm thick thin wood;

[0013] Veneer: Use a glue applicator to apply primer on high-density boards or medium-density boards, wooden multi-layer boards, particle boards, particle board...

Embodiment 2

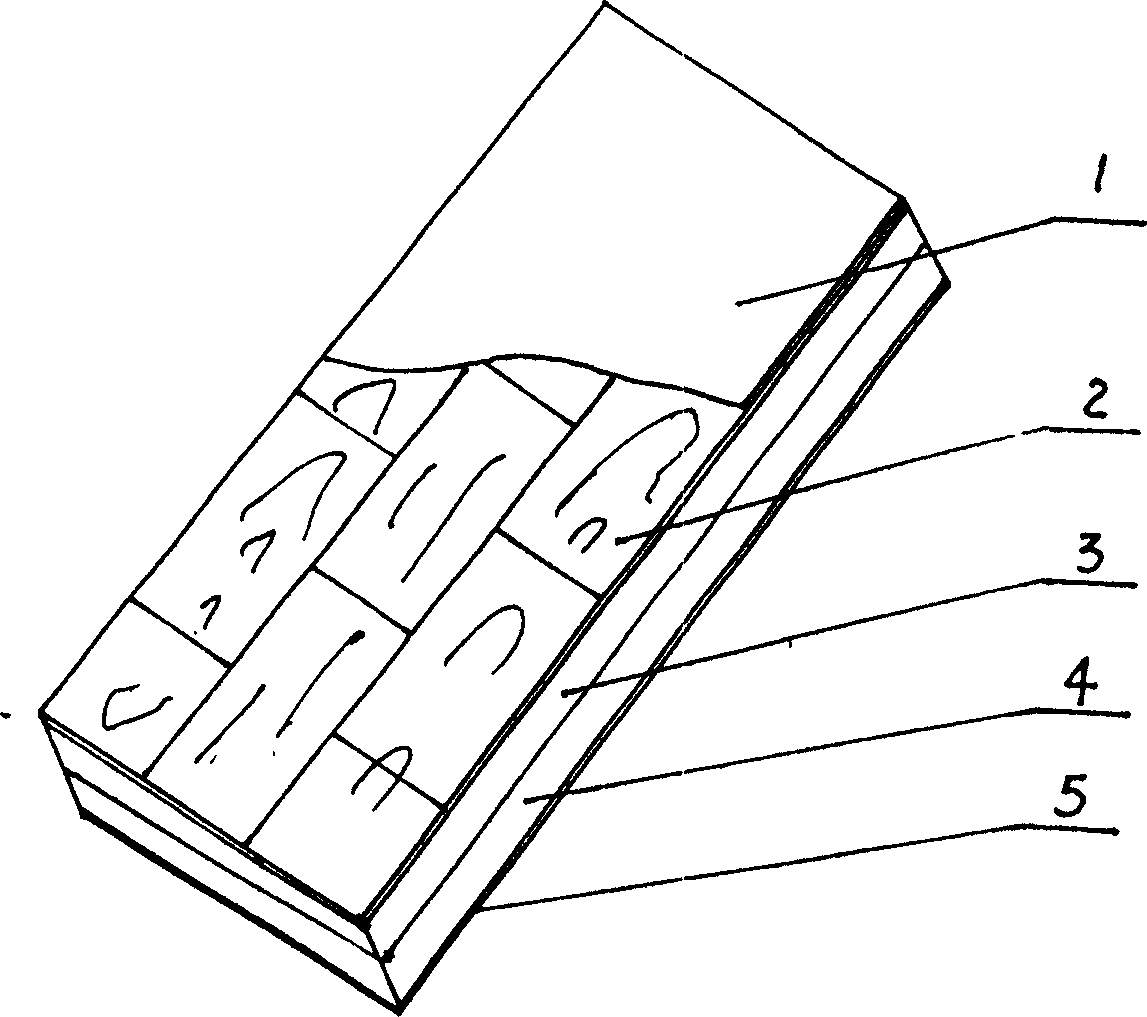

[0016] For further explanation in conjunction with the accompanying drawings, see figure 1 , in the figure: 1 is the surface wear-resistant layer, 2 is the thin wood layer, 3 is the substrate layer, 4 is the balance layer, and 5 is the bottom wear-resistant layer.

[0017] The surface wear-resistant layer 1 and the bottom wear-resistant layer 5 of the composite reinforced board made of solid wood are aluminum oxide wear-resistant layers. , rosewood, sandalwood, rosewood, cherry wood, Southwestern birch, Fraxinus mandshurica, ash wood, yellow pineapple, sawed and cut into standard timber, soaked in hot water with a temperature above 50 ℃, choose half-rotation radius, rotation Wood blocks with different diameters or color differences are used for process matching, bonded with water-resistant high-strength adhesive, and then pressed into shape by a cold press and a presser, and sliced into 20mm thick thin wood layers 2, thin wood Layer 2 and high-density substrate layer 3 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com