Method for testing levulinic acid in soy sauce

A technique for measuring levulinic acid and its method, which is applied in the field of testing and testing to achieve the effects of protecting legitimate interests, promoting fair competition, and protecting physical and mental health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

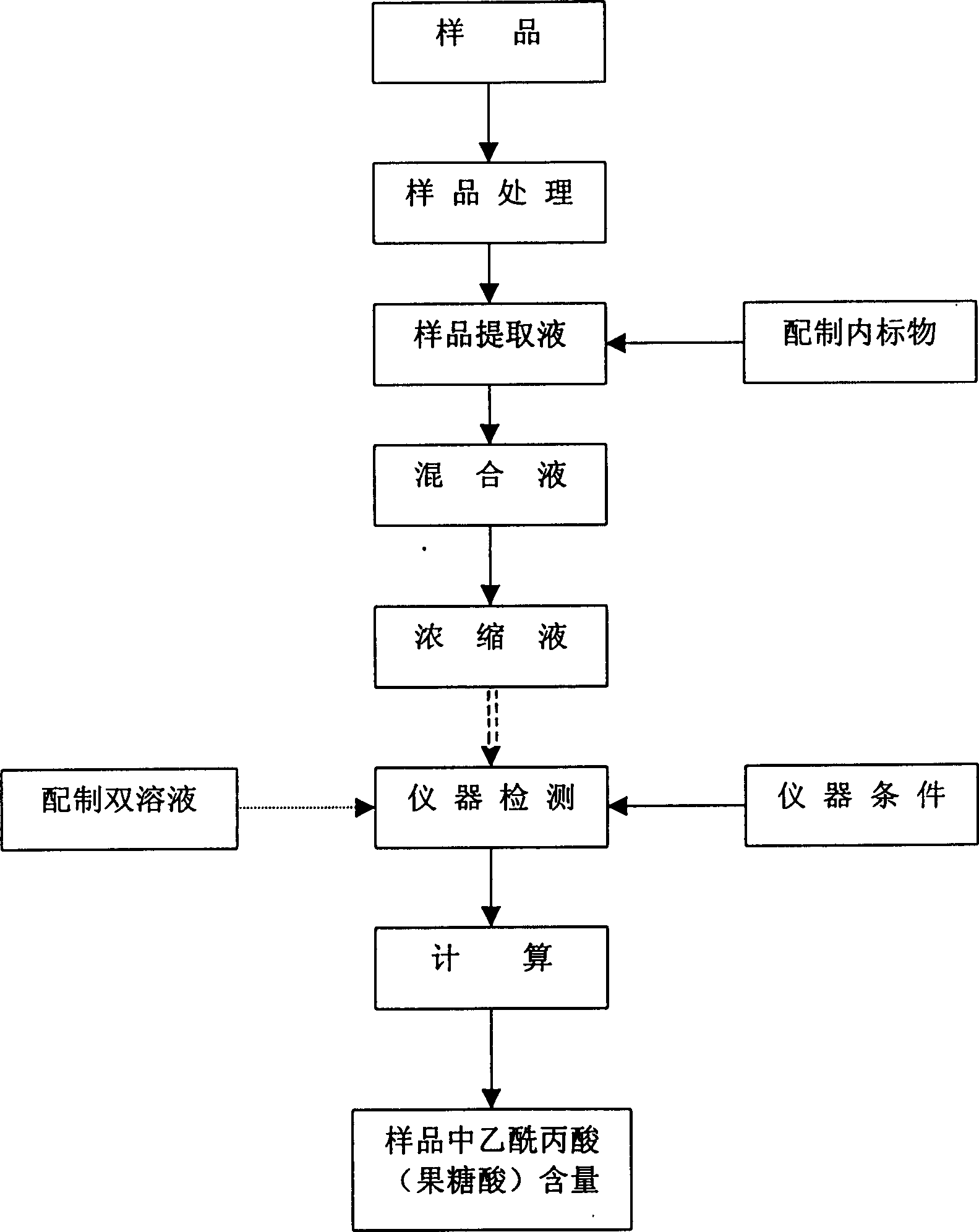

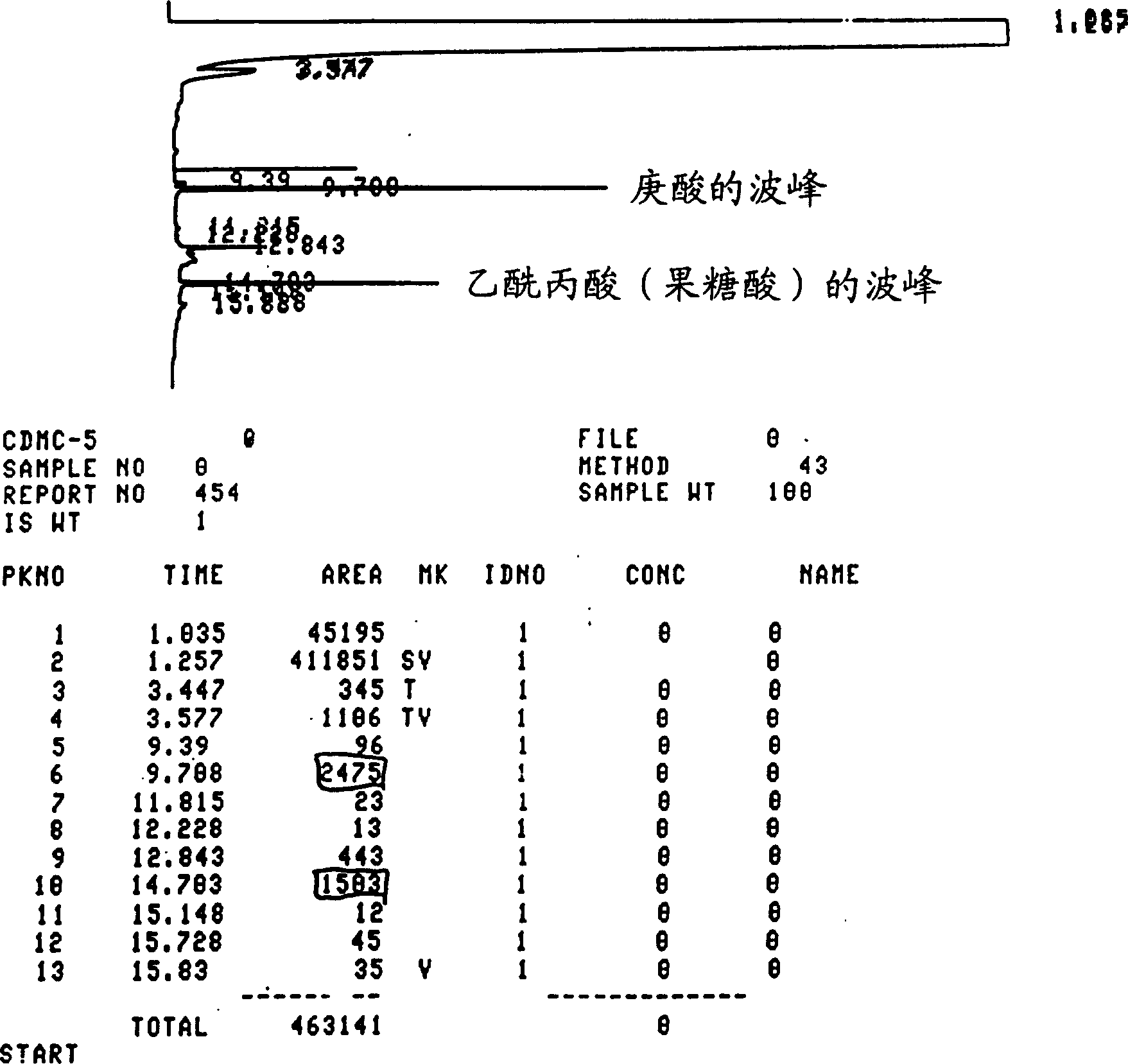

[0040] As attached to the manual figure 1 As indicated, the internal standard method of gas chromatography was used. It was detected by a gas chromatograph equipped with a hydrogen flame ionization detector, and quantified by the internal standard method. The instrument conditions are: the carrier gas of the gas chromatograph is high-purity nitrogen, the split ratio of the split capillary column is 1:100, the pressure is 411900Pa, the detection temperature of the hydrogen flame ionization detector attached to the gas chromatograph is 270°C, hydrogen The pressure is 58800Pa, and the air pressure is 58800Pa.

Embodiment 2

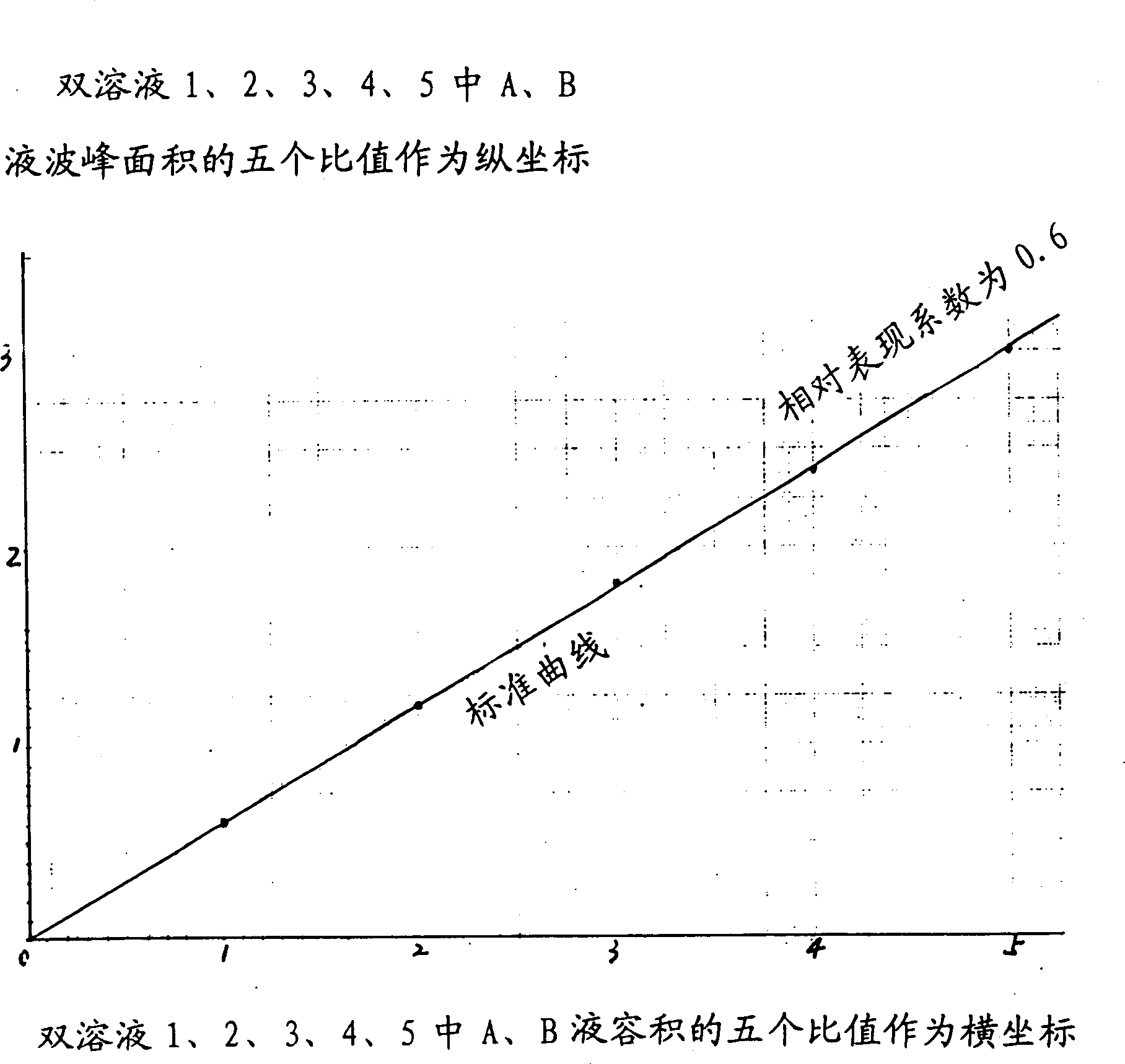

[0042] As attached to the manual figure 1 As shown, the preparation of double solutions: 0.5 ml of levulinic acid (fructonic acid) solution plus 99.5 ml of acetonitrile solution obtained by constant volume A liquid; 0.5 ml of heptanoic acid solution plus 99.5 ml of acetonitrile solution by constant volume to obtain B liquid; A liquid 2 ml and 5 ml of liquid B to obtain a double solution 1, 3 ml of liquid A and 4 ml of liquid B to obtain a double solution 2, 4 ml of liquid A and 3 ml of liquid B to obtain a double solution 3, 5 ml of liquid A and 2 ml of liquid B to obtain a double solution Double solution 4, 6 ml of solution A and 1 ml of solution B were used to obtain double solution 5, and a total of five double solutions were prepared.

Embodiment 3

[0044] As attached to the manual figure 1 As shown, prepare the internal standard: add 99.5 ml of acetonitrile solution to 0.5 ml of heptanoic acid solution to obtain the prepared internal standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com