Method for extracting papermaking black liquor

A technology of papermaking black liquor and black liquor, which is applied in the field of extracting straw pulp and papermaking black liquor, can solve the problems of incomplete extraction of black liquor and sewage discharge, achieve good washing effect, reduce pollution load, and increase production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

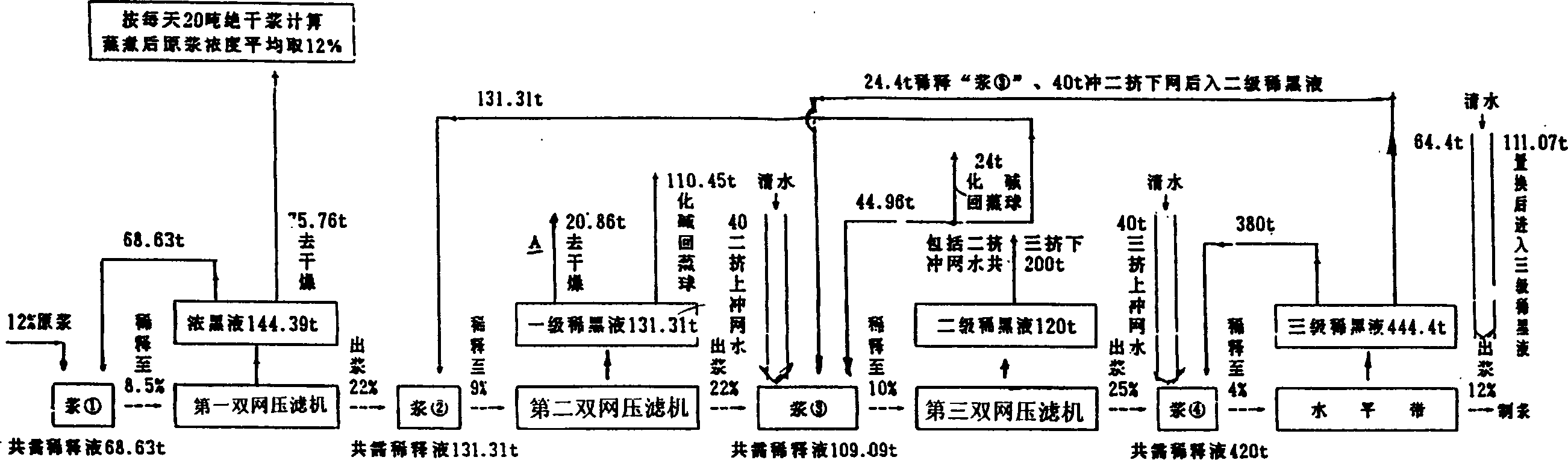

[0018] refer to figure 1 The method for extracting papermaking black liquor of the present invention is specifically described. In this preferred embodiment, the black liquor extraction equipment is a double-screen filter press and a horizontal belt washer. Specific steps are as follows:

[0019] ① Add 68.63 tons of diluent to dilute the raw pulp with a concentration of 12% sprayed from the steaming ball to a pulp 1 with a concentration of 8-9%. Pressing out 144.39 tons of dense black liquor, 75.76 tons of which are sent to dry, 68.63 tons are returned to the original pulp for the described dilution, and the concentration of the remaining slurry is 22%;

[0020] ② Dilute the slurry 2 from the first double-net filter press to 9%, and then pump it into the second double-net filter press for extrusion filtration. The filtered first-class dilute black liquor is 131.31 tons, of which 110.45 20.86 tons of alkali return steaming balls were sent to dry;

[0021] 3. Rinse the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com