Acrylonitrile quench method

An acrylonitrile quenching technology, applied in the field of acrylonitrile quenching, can solve problems such as easy blockage of tower equipment, unreasonable gas-liquid distribution, increased loss of acrylonitrile, etc., to reduce dissolution loss, reduce diffusion and horizontal back mixing, reduce Effect of Aggregation Opportunities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

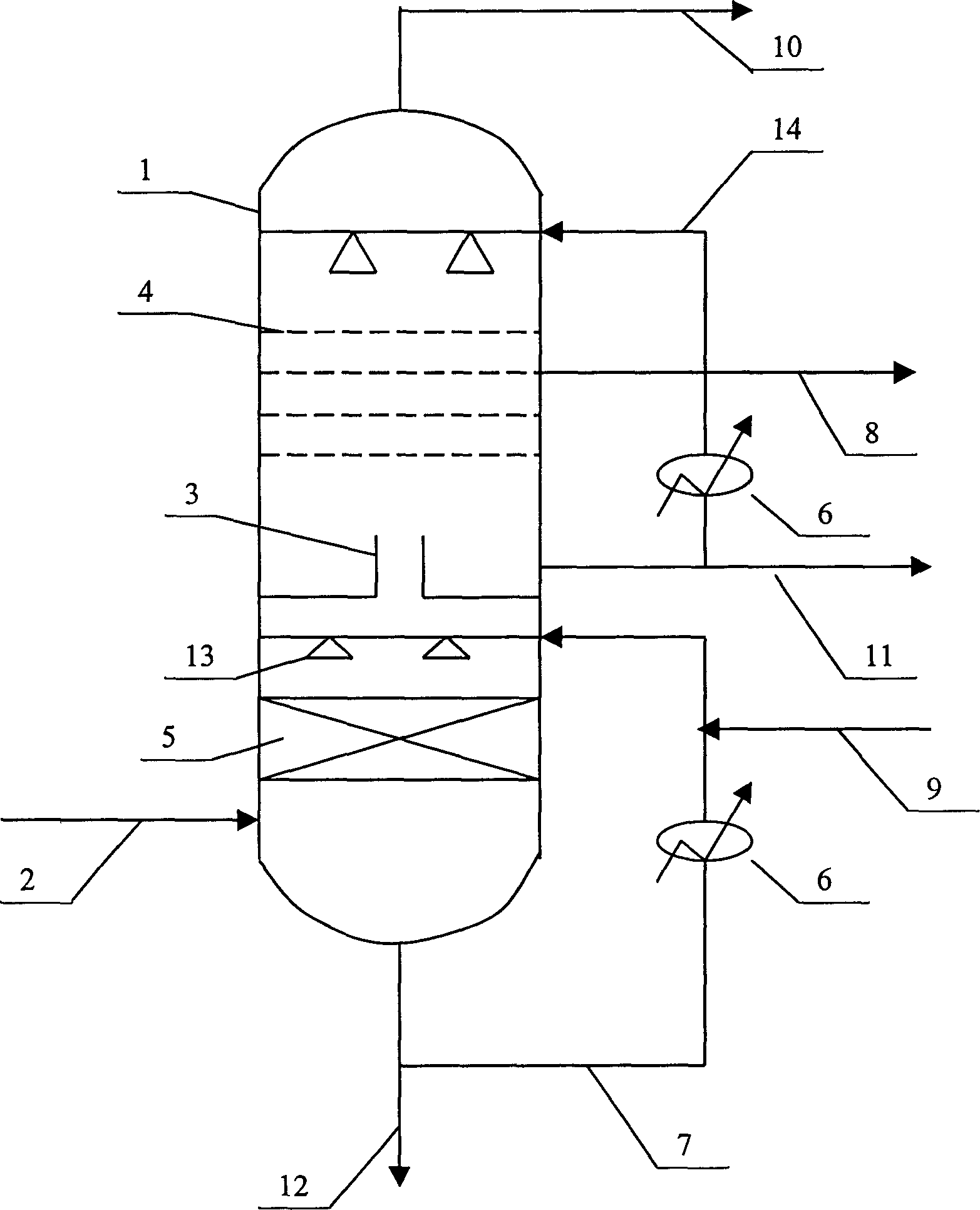

[0032] The composition (% by weight) of the reactor tail gas was: acrylonitrile 12.4, acetonitrile 0.5, hydrocyanic acid 1.4, acrolein 0.1, acrylic acid 0.3, ammonia 0.3, and others 85.0. The flow rate is 9.25 tons / hour, the feed temperature is 220 °C, and the quenching tower of the present invention is adopted, the lower section of the external circulating liquid is sprayed with 5 layers, the nozzle installation angles are 0°, 30°, and 150°, and the inner components of the lower section are composed of external It is a circle, the internal channel is composed of equilateral triangle packing units, the number of packing units is 7, D2=0.5D1, d2=0.5d1, the arithmetic average cross-sectional area of the internal passages of all the packing units is 75% of the cross-sectional area of the tower, and the lower section does not Add acid; the number of plates in the upper section is 8, and the pH value of the external circulating liquid is controlled to be 3.0. The recovery rate ...

Embodiment 2

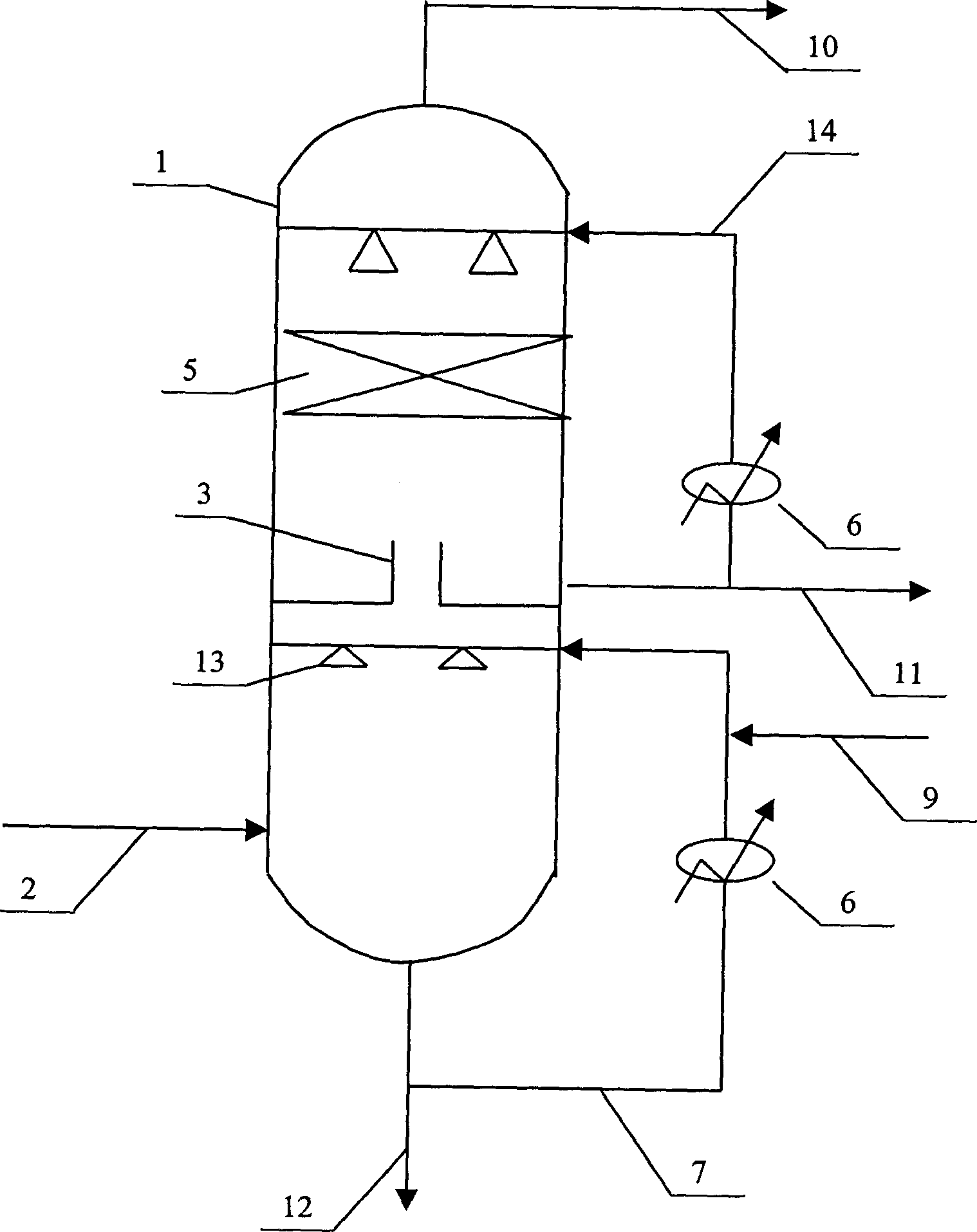

[0034] The composition (% by weight) of the reactor tail gas was: acrylonitrile 12.4, acetonitrile 0.5, hydrocyanic acid 1.4, acrolein 0.1, acrylic acid 0.3, ammonia 0.3, and others 85.0. The flow rate is 9.25 tons / hour, the feed temperature is 220°C, and the quenching method of the present invention is adopted, the lower section of the external circulating liquid is sprayed into 3 layers, the nozzle installation angles are 0°, 120°, and 180°, and the lower section internal components are composed of external It is circular, and the internal channel is composed of regular pentagon packing units. The number of packing units is 4, D2=0.75D1, d2=0.75d1, and the arithmetic average cross-sectional area of the internal channel of all packing units is 45% of the column cross-sectional area. No acid is added in the lower section; the number of plates in the upper section is 5, and the pH value of the control external circulation liquid is 3.0. The recovery rate of acrylonitrile in t...

Embodiment 3

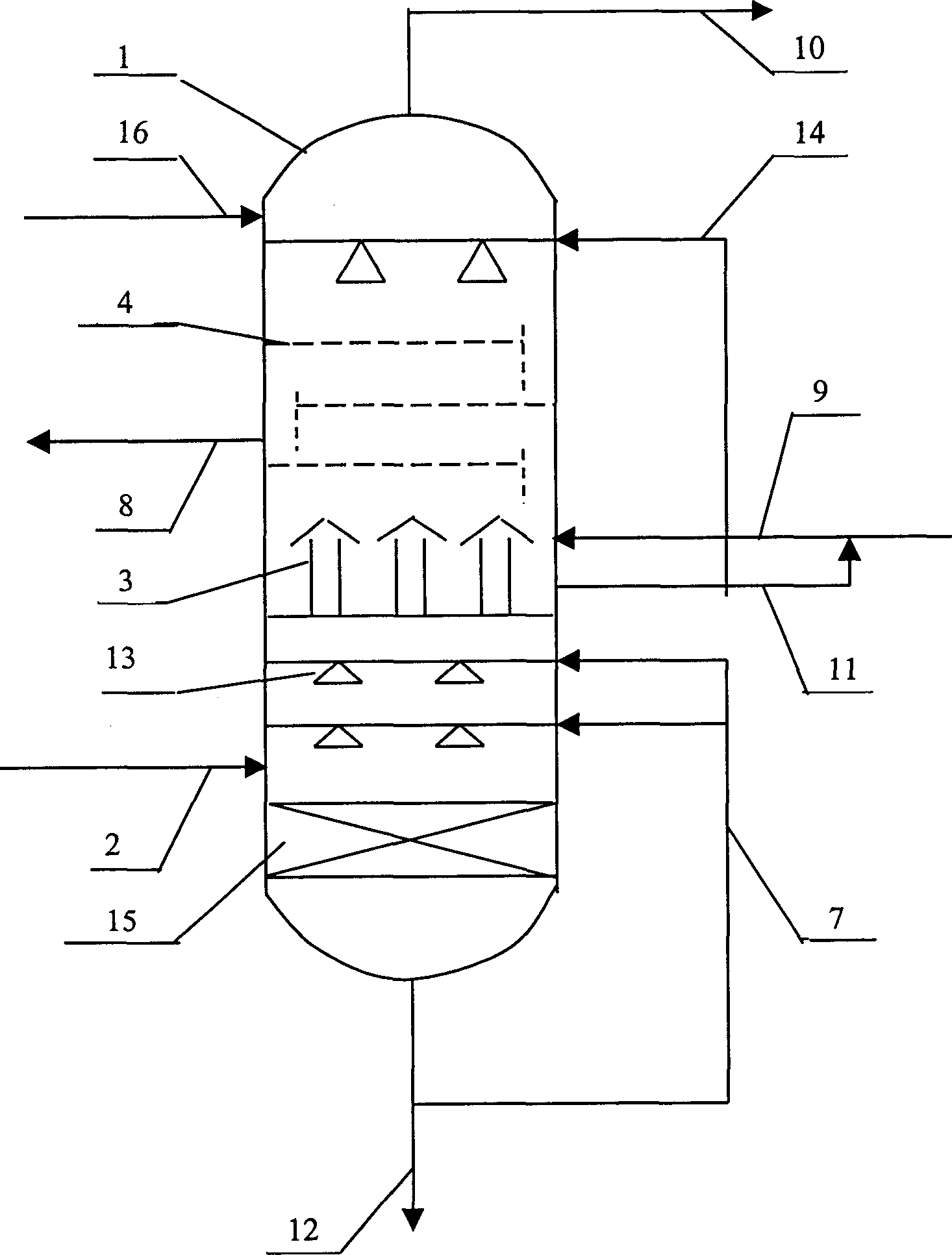

[0036] The composition (% by weight) of the reactor tail gas was: acrylonitrile 12.4, acetonitrile 0.5, hydrocyanic acid 1.4, acrolein 0.1, acrylic acid 0.3, ammonia 0.3, and others 85.0. The flow rate is 9.25 tons / hour, the feed temperature is 220°C, and the quenching method of the present invention is adopted. The lower section of the outer circulating liquid is sprayed with two layers, the nozzle installation angles are 30° and 150°, and the inner components of the lower section are circular from the outside. , the internal channel is also composed of circular packing units, the number of packing units is 6, D2=D1, d2=d1, the arithmetic average cross-sectional area of the internal channel of all packing units is 25% of the cross-sectional area of the tower, and no acid is added in the lower section; The number of trays is 3, and the pH value of the external circulating liquid is controlled to be 3.0. The recovery rate of acrylonitrile in the quench tower was 95.6%, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com