Eccentric flexible directly driving screw winder without belt driving

A technology of spiral winding and belt transmission, which is applied in the field of eccentric direct transmission spiral winding machines without belt transmission, which can solve the problems of waste of bales, influence on the flatness of the net, and influence, etc., and achieve wide speed regulation range and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

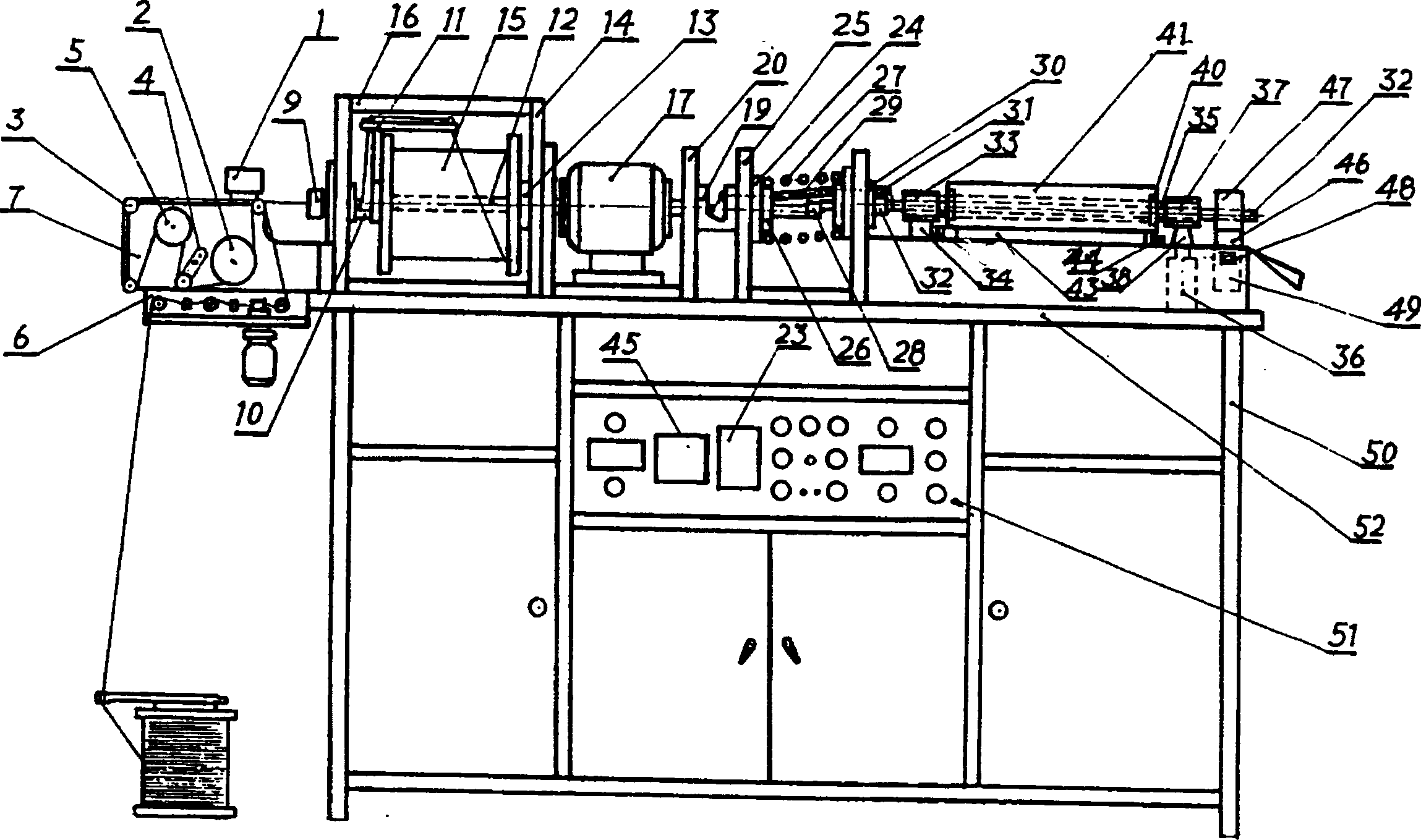

Image

Examples

Embodiment Construction

[0045] After inserting the polyester monofilament into the center hole of the two silk spools of the silk spool and the wire feeding guide tube 12, put them into the left and right spiral ring synchronization modules respectively, and lead the monofilament head through the wire feeding module to the wire winding nozzle and pull out a section . Plug in total power supply lock 68 keys and open total power supply lock switch, connect power supply, total power supply index lamp 70 is bright, and supply voltage digital display table 69 shows the complete machine supply voltage value at that time. Adjust the speed of the drive motor of the left and right spiral winding heads to 100 rpm

[0046] put on. Start the heater button 54, the heater working indicator light 55 is on, and the heater starts to preheat, and the preheating time is 5 to 10 minutes. After setting the switch of the wire feeding motor and the ring feeding motor to the automatic position, one of the left and right w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com