Stave cooler

A technology for plate coolers and cooling furnaces, applied in cooling devices, furnace cooling devices, furnace cooling, etc., can solve problems such as low work efficiency, high manufacturing costs, and low support strength of stainless steel blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

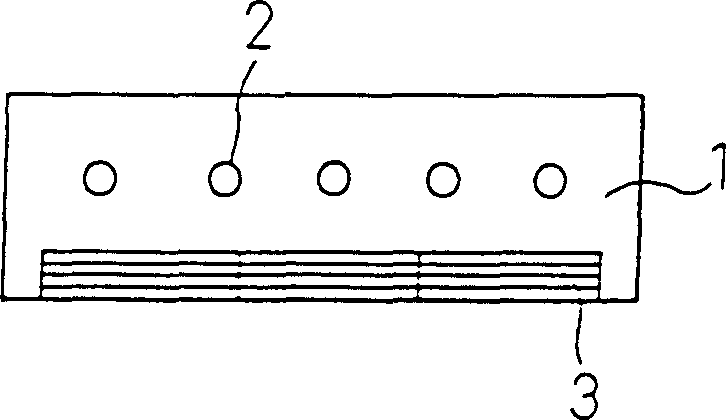

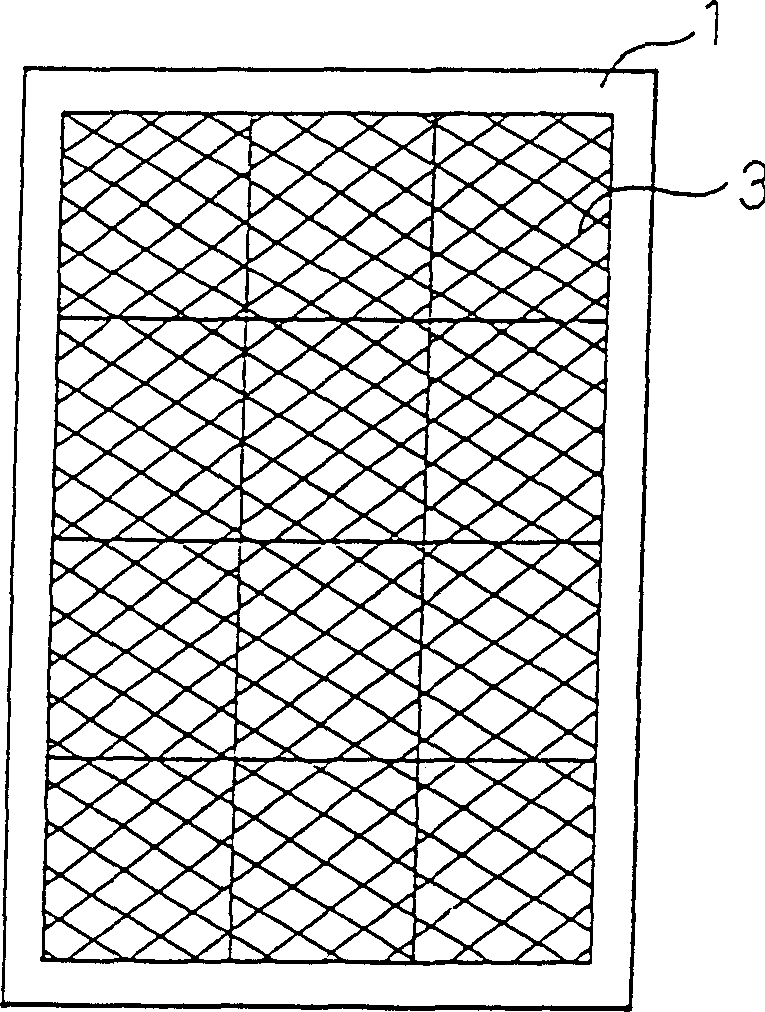

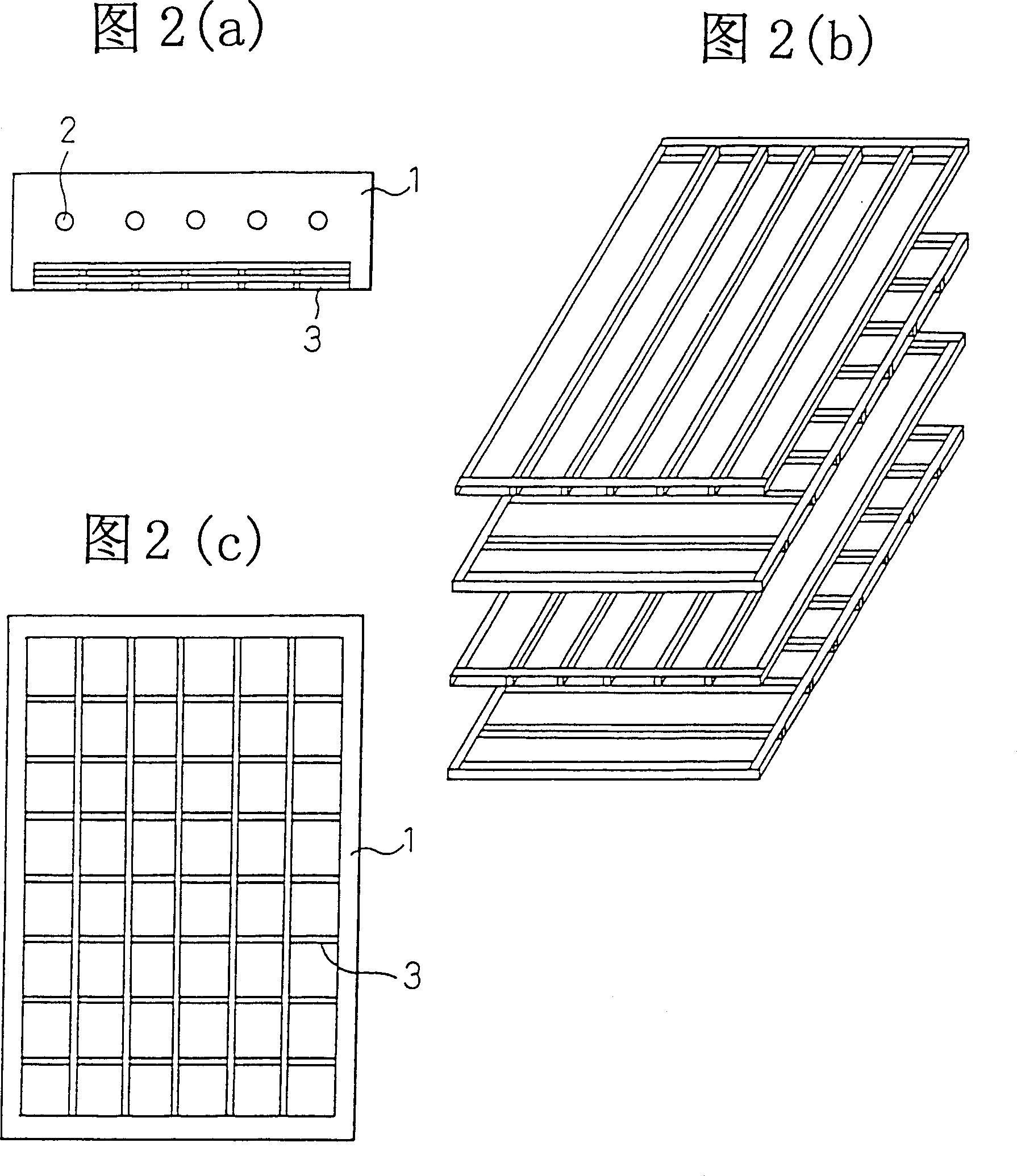

[0051] The present invention adopts a structure in which a heat-resistant steel plate excellent in wear resistance and fracture resistance under high temperature and high abrasion environments is cast on the furnace inner surface of the plate cooler.

[0052] The heat-resistant steel is required to have excellent thermal insulation performance, high-temperature strength, high-temperature corrosion resistance, high-temperature stability (deformation resistance), and the like in addition to the above.

[0053] Heat-resistant steel of any chemical composition can be used for the purpose of the present invention as long as it satisfies the above-mentioned required characteristics, but, in practice, the most suitable heat-resistant steel should consider the temperature and other environmental conditions of the plate cooler and the steel's Chemical properties are selected.

[0054] Austenitic heat-resistant steels (such as 18Cr-8Ni steel, 22Cr-12Ni steel, and 25Cr-20Ni steel, etc.) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com