Pseudospherical collimation microlens for optic fibre collimator

A technology of optical fiber collimator and spherical collimation, which is applied in the direction of lens, optical waveguide coupling, instrument, etc., can solve the problems of optical signal loss, insertion loss increase, etc., achieve long working distance, eliminate aberration, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

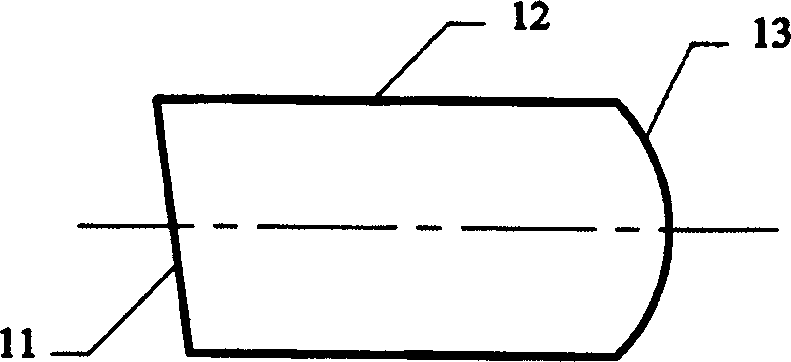

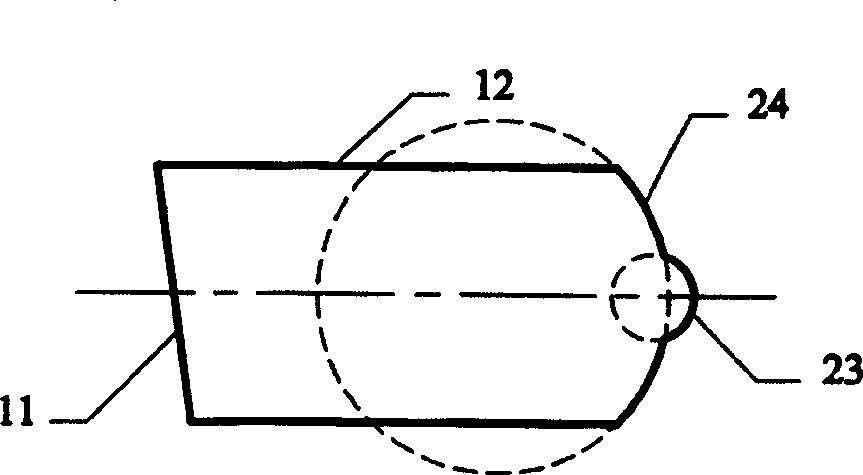

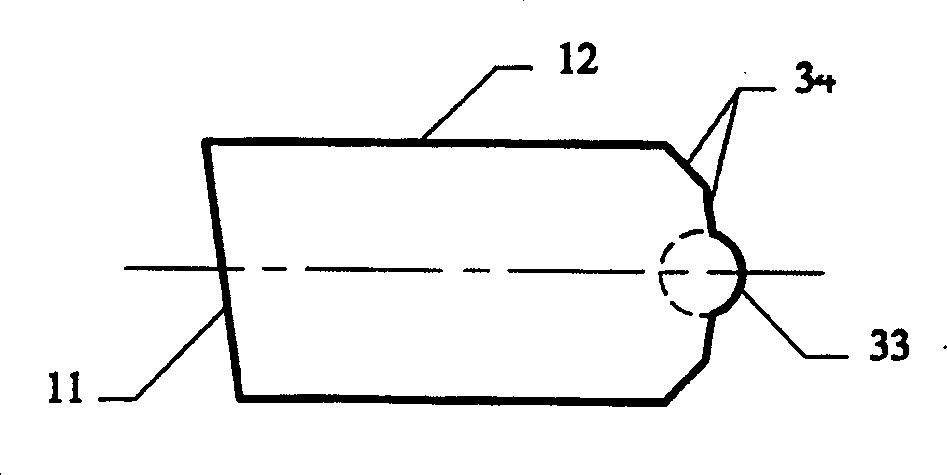

[0014] The above pseudospherical collimating microlens used in the fiber collimator has a pseudospherical end surface with a vertical axis, a cylindrical side surface and another inclined end surface. The lens material is a homogeneous refractive index optical material. The pseudospherical vertical axis end surface is formed by a combination of coaxial spherical surfaces 23 and 24 with different curvatures or conical surfaces 33 and 34 with different inclination angles, and is perpendicular to the main axis of the pseudospherical collimating microlens used in the fiber collimator. The surface shape of the inclined end surface is a plane, and its normal line forms an included angle of 6∽12° with the main axis of the pseudospherical collimating microlens used for the fiber collimator. Pseudo-spherical vertical axis end face and inclined end face are coated with anti-reflection coating.

[0015] The processing of the pseudo-spherical collimating microlens used in the fiber colli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com