Slider of slide fastener

A technology of zipper and linear body, applied in the field of zipper slider, which can solve the problems of long-term and stable use of the slider, disengagement, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

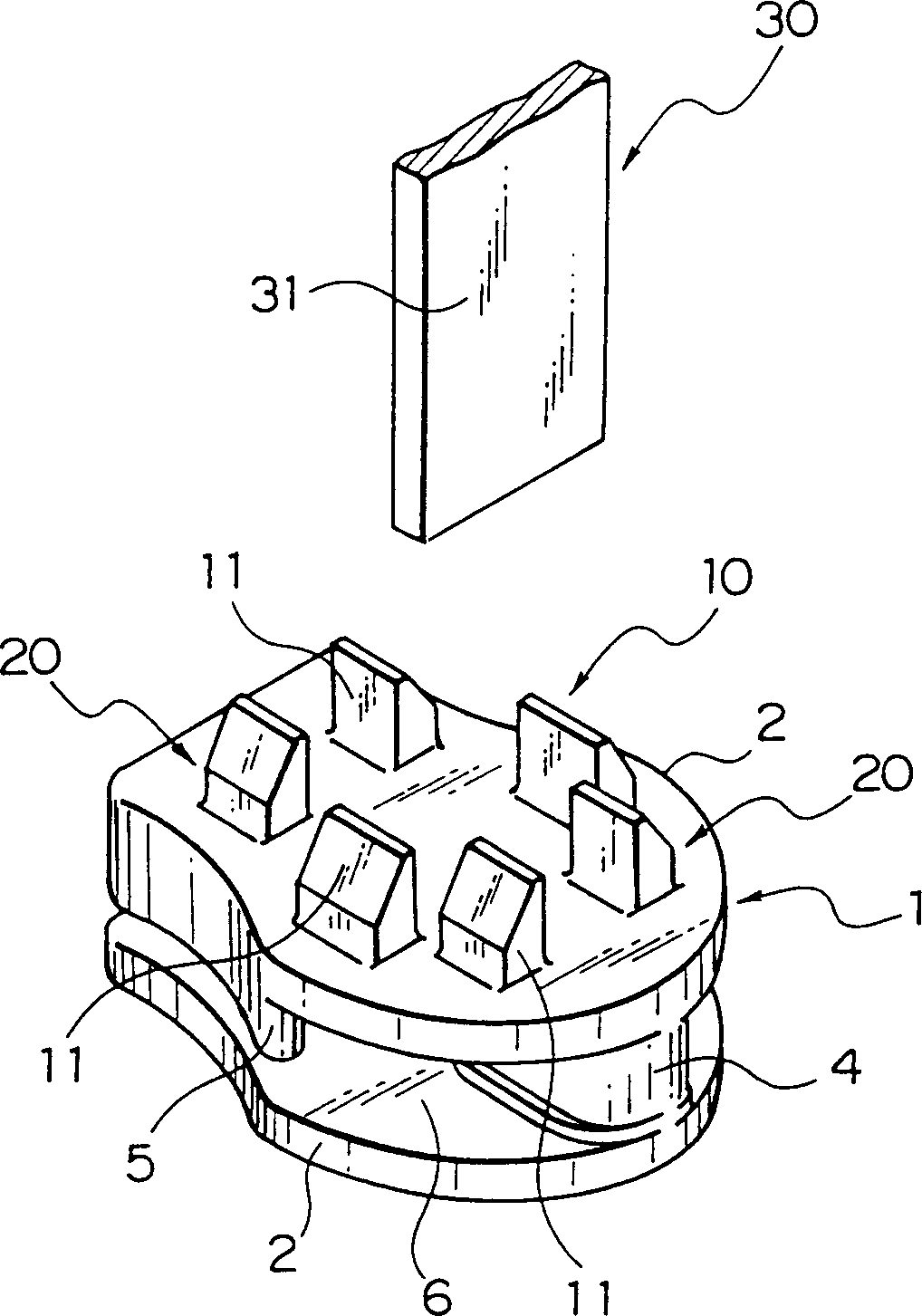

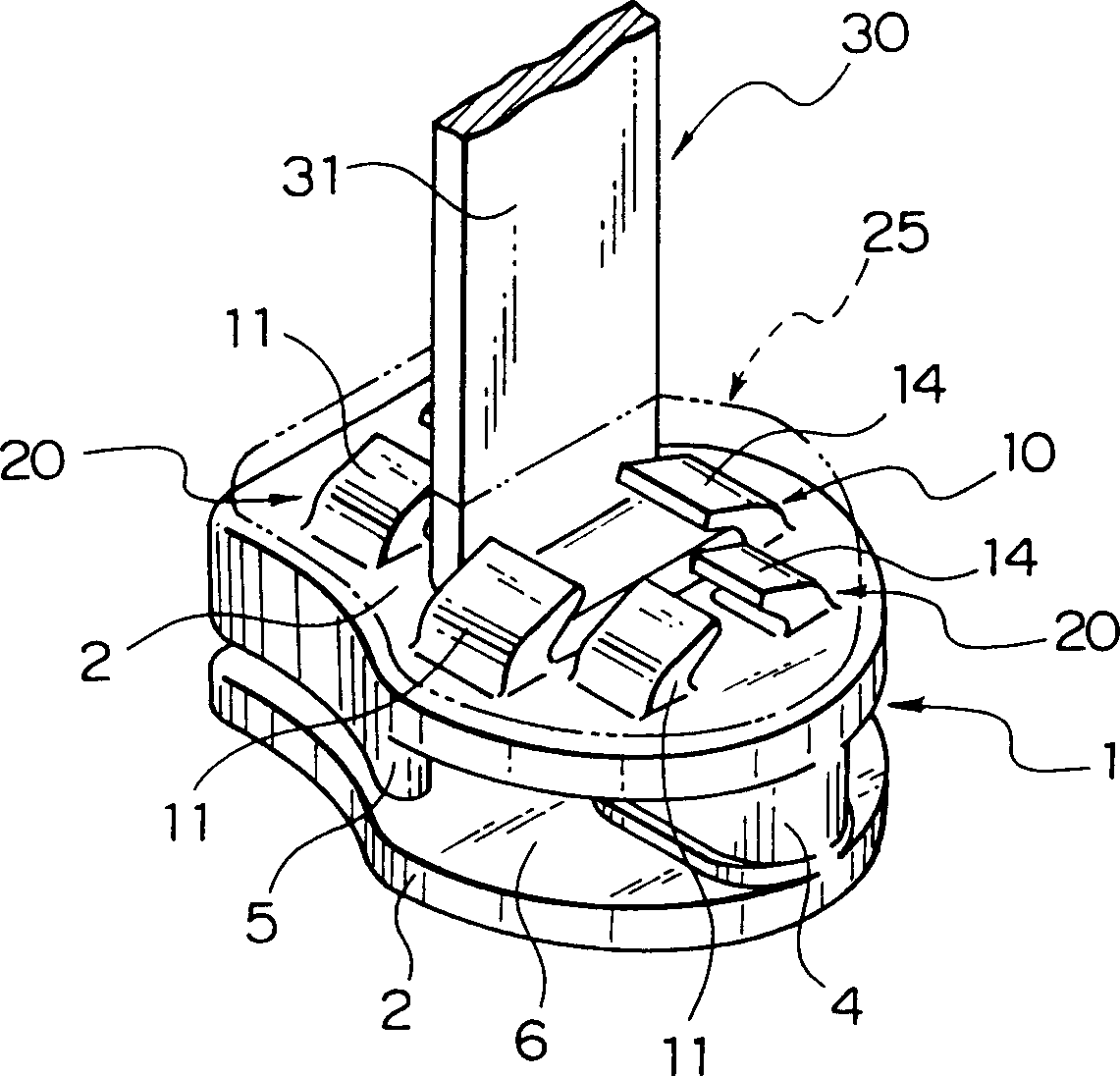

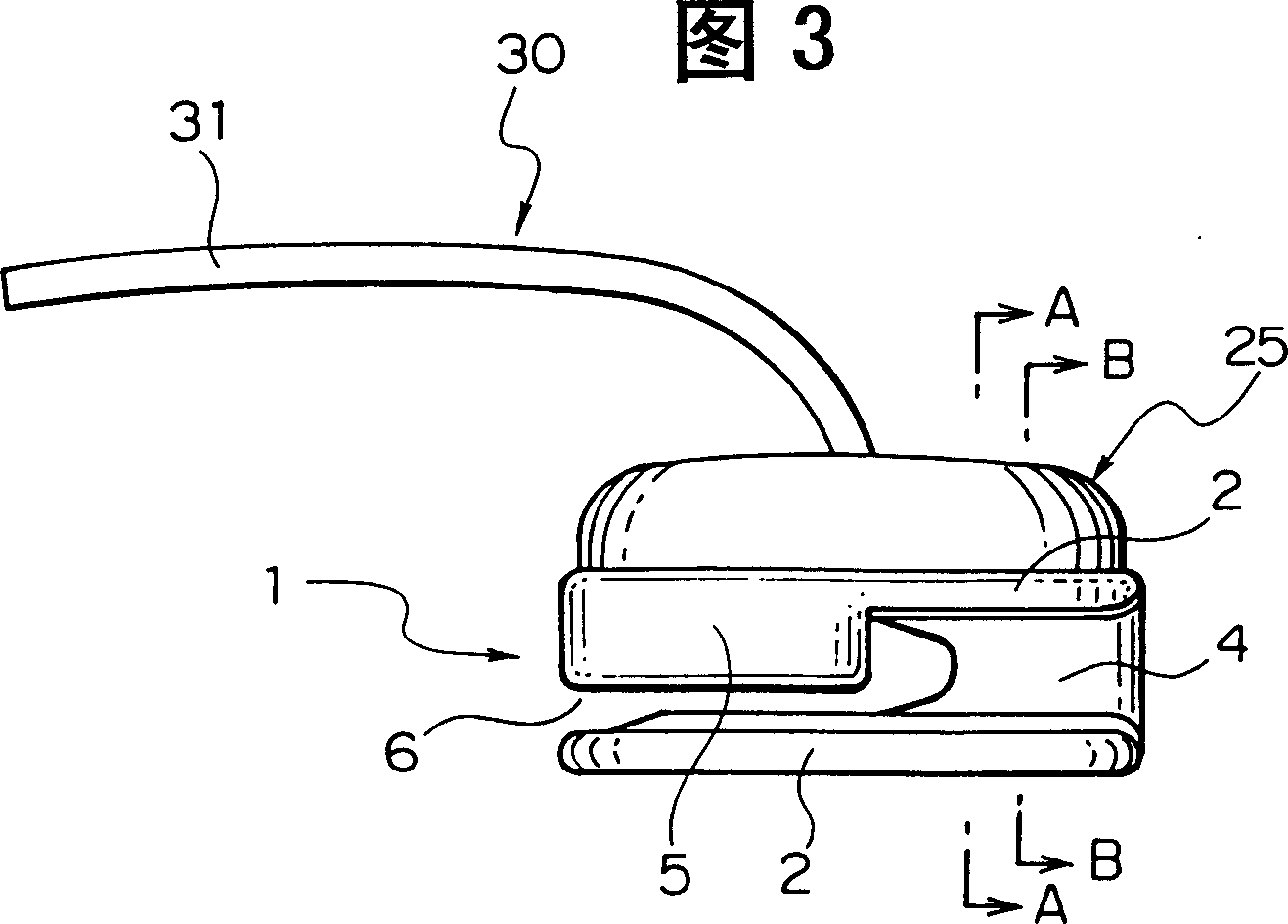

[0041] Preferred embodiments of the zipper slider will be described in detail below with reference to the accompanying drawings.

[0042] In the zipper slider of the present invention, the main slider body 1 is made of double-cast zinc alloy or aluminum alloy, and the linear body 30 is made of knitted or braided synthetic resin yarn, and the linear body is mounted on the top of the body 1. On the surface, as a pull pan. To mount the linear body 30 on the main body 1, a molded resin body 25 is formed on the main body 1 by insert molding such as polyurethane and polyester, thereby fixing the linear body 30 to the main body 1, thereby making a slider without any protrusions on the surface of the body 1. The body 1 of the slider can be made of polyamide, polyester and polypropylene as well as metal. In addition, the molded resin body 25 on the body 1 can be made of synthetic resin or rubber such as vinyl chloride, polyethylene, polyamide, polypropylene.

[0043] The linear body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com