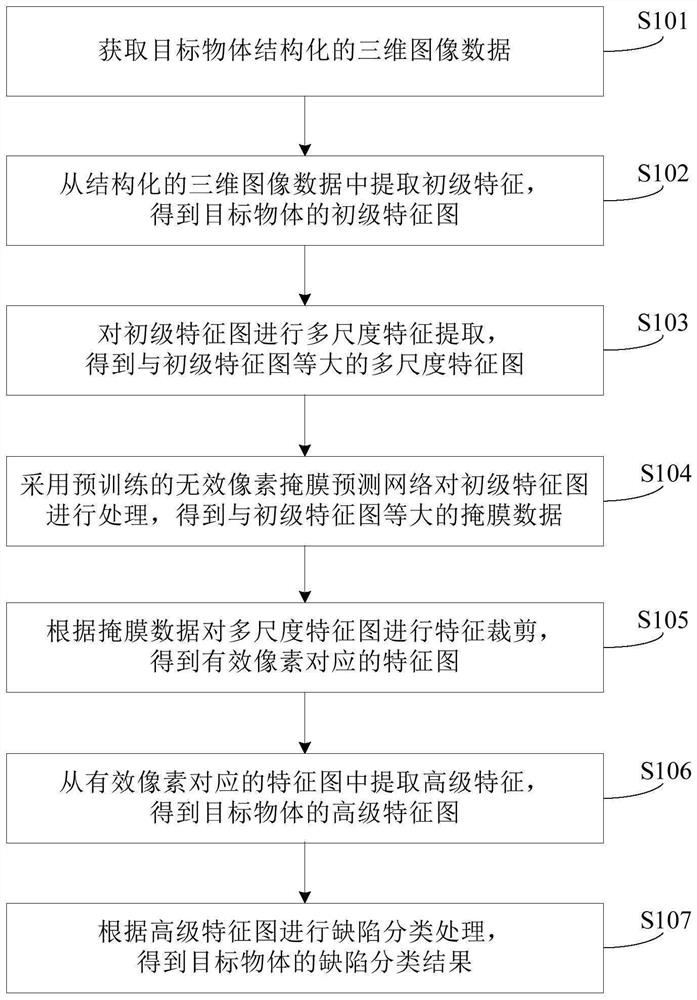

Surface defect detection method and equipment based on three-dimensional image

A technology for three-dimensional image and defect detection, which is applied in the field of image processing, can solve the problems of inability to obtain pixel height information, reduce the accuracy of surface defect detection, and low efficiency, and achieve the effects of real-time detection, improved efficiency, and less time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

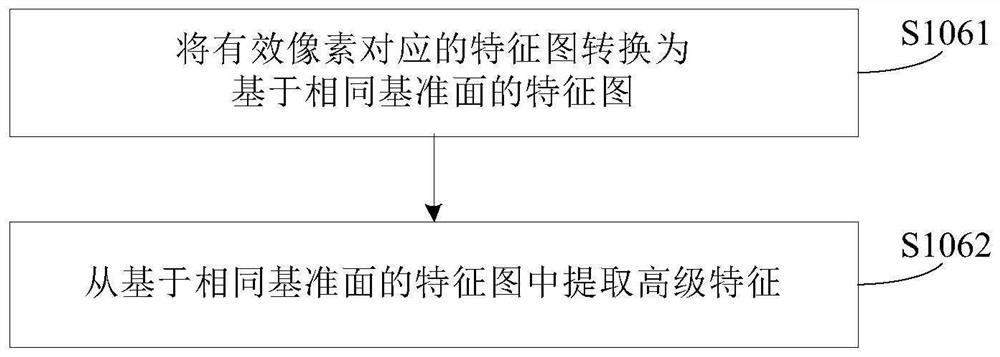

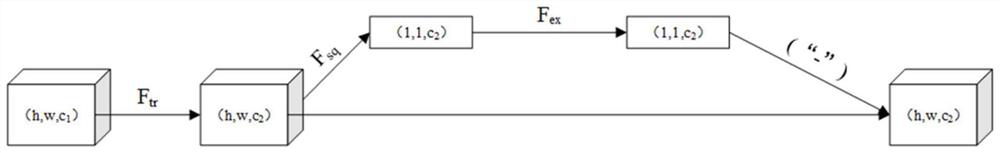

Method used

Image

Examples

Embodiment Construction

[0052]The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. Wherein similar elements in different embodiments have used associated similar element numbers. In the following embodiments, many details are described so that the present application can be better understood. However, those skilled in the art will readily recognize that some of the features may be omitted in different situations, or may be replaced by other elements, materials, and methods. In some cases, some operations related to the present application are not shown or described in the specification, in order to avoid the core part of the present application from being overwhelmed by excessive description, and for those skilled in the art, these are described in detail. The relevant operations are not necessary, and they can fully understand the relevant operations according to the descriptions in the specification and general ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com