Array ultrasonic instrument test platform and method

An ultrasonic instrument and testing platform technology, applied in instruments, scientific instruments, material analysis using sound waves/ultrasonic waves/infrasonic waves, etc., can solve problems such as interface damage and heavy workload, reduce signal attenuation and distortion, and ensure safety , the effect of accurate test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

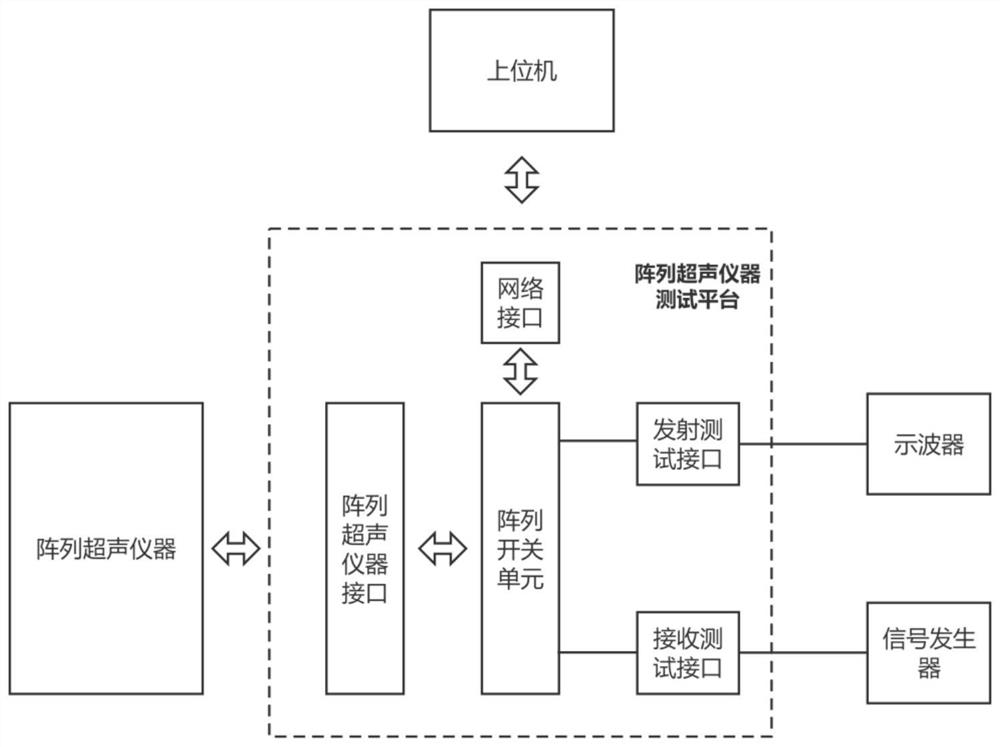

[0041] In this embodiment, the array ultrasonic instrument includes 128 channels, such as Figure 1-2 As shown in the figure, the 128-channel ultrasonic instrument signal of the array ultrasonic instrument is switched to 2 test channels (one transmitting and one receiving) at the other end. After equipped with standard instruments such as signal generator and oscilloscope, it can meet the testing requirements of the array ultrasonic instrument. For example, switch the channel N of the ultrasound instrument to the transmit test channel, and match the transmit parameters (transmit voltage, pulse edge time, transmit output impedance, etc.) of the oscilloscope test channel N; switch the channel N of the ultrasound instrument to the receive test channel, and match the signal The generator tests channel N's receive parameters (bandwidth, equivalent input noise, vertical linearity, etc.).

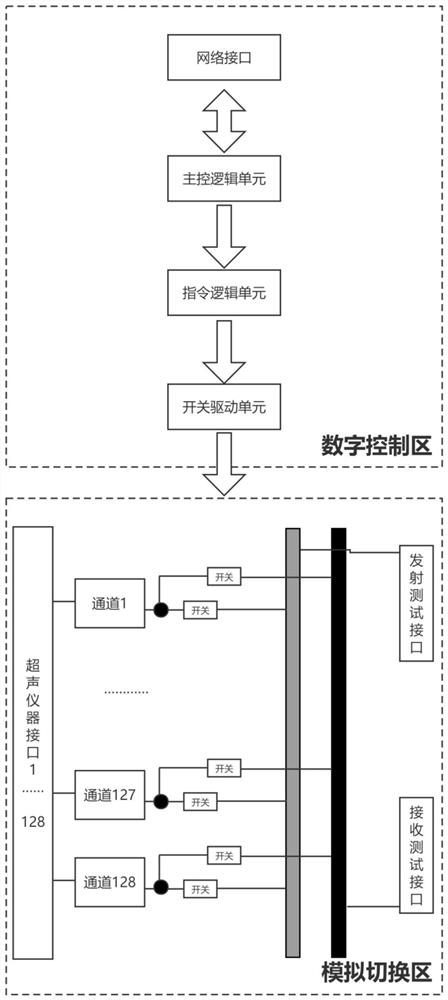

[0042] An implementation of the present invention is as follows: figure 2 The shown "network...

Embodiment 2

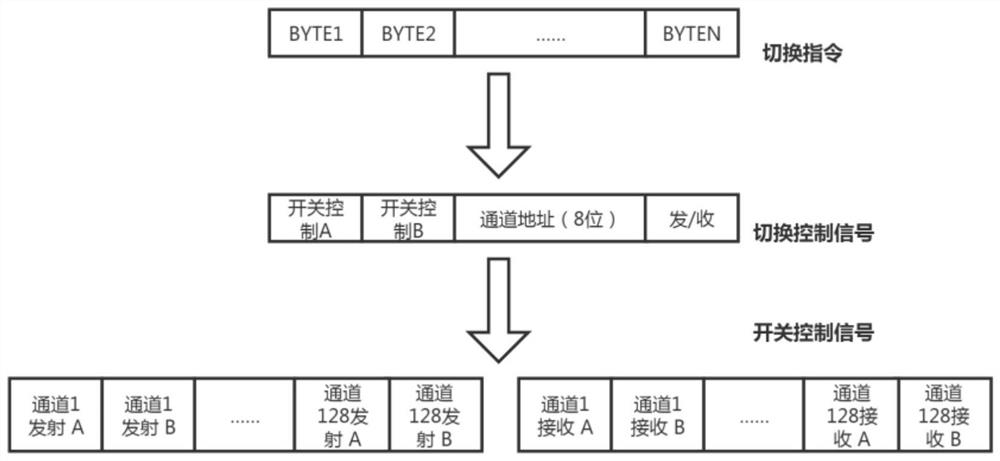

[0072] When the ultrasonic channel of the array ultrasonic instrument works in the transmitting state, there will be high-voltage pulses (the pulse voltage is usually above 100 volts). In order to ensure that the switching of the test platform does not damage the ultrasonic instrument, the Figure 4 The switching logic shown, the system enters the reset state after power-on, and switches the 128 ultrasonic channels to the state where they are not connected to the transmit test channel and the receive test channel in turn; then wait for the transmit and receive switching instructions to be obtained and parsed. Switch the ultrasonic channel in the previous "transmission switching command" to the disconnected state, save the current "transmission switching command", connect the ultrasonic channel in the current "transmission switching command" to the transmission test channel, and put the previous "receive switching command" The ultrasonic channel in the switch to the disconnected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Characteristic impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com