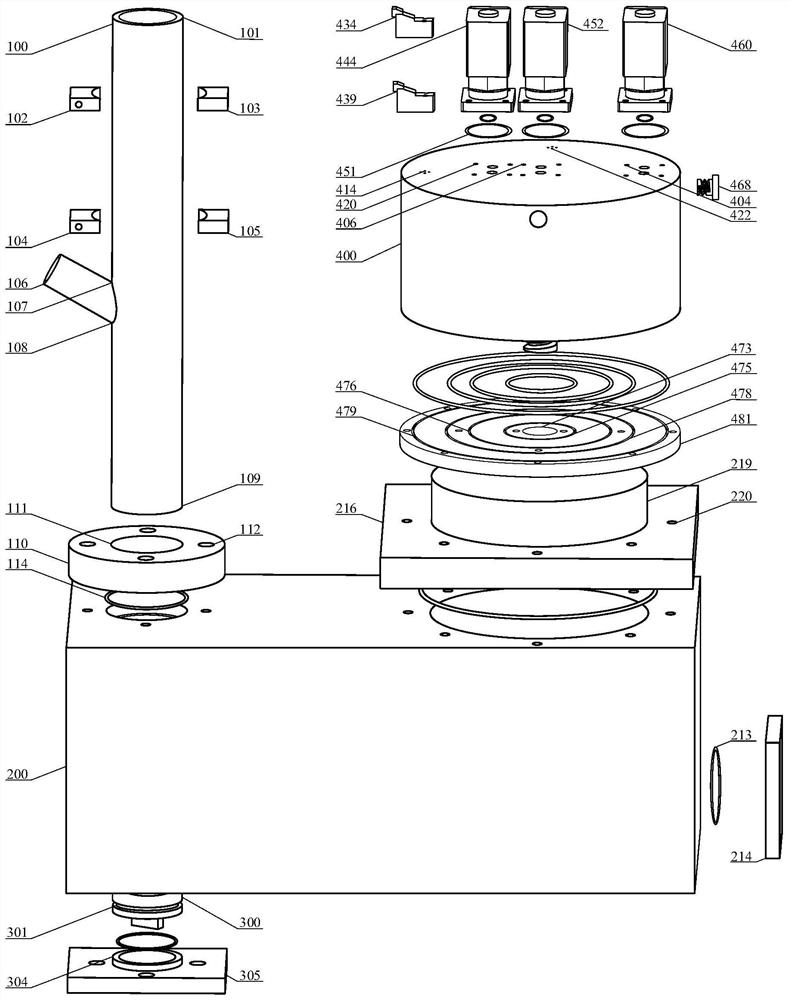

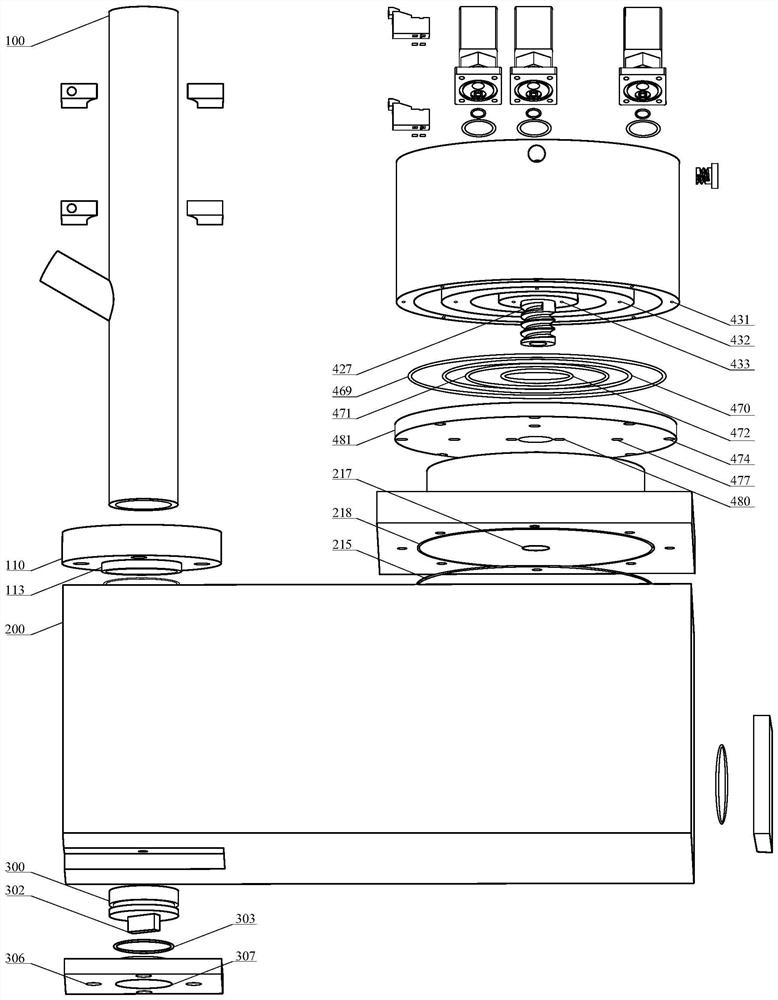

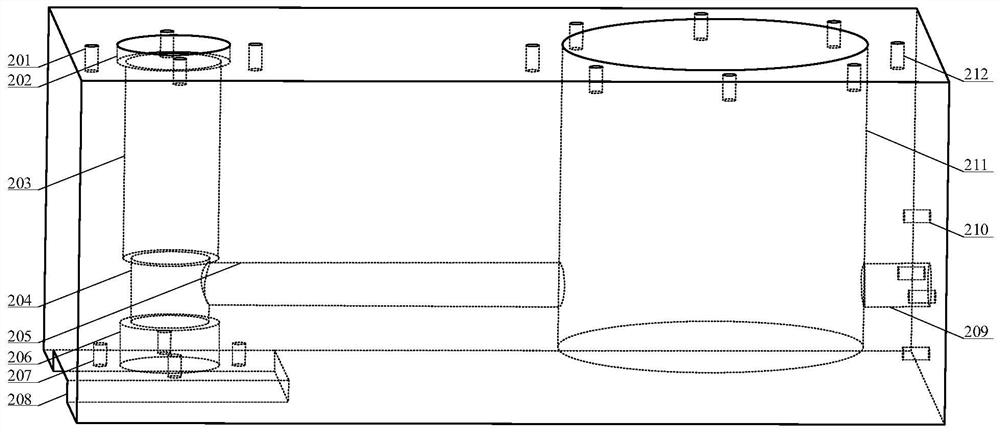

Soap film flowmeter capable of automatically wetting soap tube and adjusting liquid level speed and testing method

A technology of soap tube and soap liquid, which is applied in the field of soap film flowmeter, can solve the problems of unable to produce soap film, poor gas circulation, small measurement results, etc., to achieve automatic measurement process, avoid the phenomenon of membrane connection, and complete measurement process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] At 25°C, the outer diameter d is 18mm, and the range V is 50mL straight-tube soap tube. In the experiment, the time t for the soap film to pass through the lower photoelectric sensor transmitting end 104 and the lower photoelectric sensor receiving end 105 is measured. 1 , through the time t of the upper photoelectric sensor transmitting end 102 and the upper photoelectric sensor receiving end 103 2 , calculate the time difference Δt and the gas flow Q V .

[0116] Table 1 Soap film flowmeter data record table

[0117]

[0118] The raw data is shown in Table 1, and the mean value is calculated, namely:

[0119]

[0120]

[0121] in: is the average of multiple measurements, mL / min;

[0122] n is the number of measurements, times;

[0123] x i is a single measurement value, mL / min.

[0124] Calculate the standard deviation S E It reflects the degree of deviation of each measurement result in the measurement sample relative to the average value, which is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com