Soap film flowmeter

A flow meter and soap film technology, applied in volume measurement, liquid/fluid solid measurement, volume/mass flow generated by mechanical effects, etc., can solve problems such as bubble burst and achieve the effect of eliminating influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

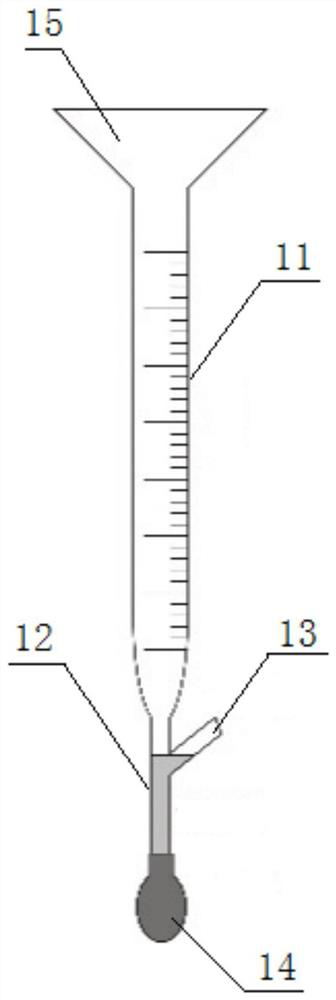

Embodiment 1

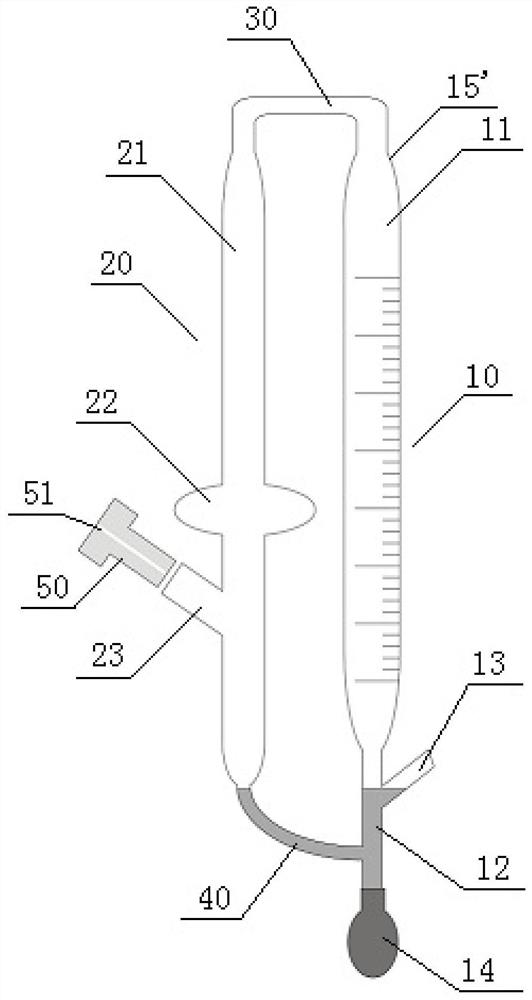

[0040] Such as figure 2 As shown, in a preferred embodiment, the parallel straight tube 20 also includes a spherical ruptured part 22, which is connected in the length direction of the straight tube main body 21 and integrally formed with it. The diameter of the spherical ruptured part 22 is larger than that of the straight tube. The diameter of the main body 21 . In this way, when the soap film bubbles descending in the straight pipe main body 21 reach the position of the spherical rupture part 22, the soap film ruptures due to the rapid expansion of the surface area. Drop or flow down the pipe wall into the foam making agent.

[0041] Preferably, the diameter of the spherical membrane rupture portion 22 is twice the diameter of the straight tube main body 21 .

[0042] Optionally, the variance of the difference between the diameter of the straight pipe main body 21 and the diameter of the metering pipe main body 11 is within 10%. Preferably, the diameter of the straight ...

Embodiment 2

[0044] In this embodiment, the parallel straight tube 20 does not include the spherical rupture portion 22, and the diameter of the parallel straight tube 20 is configured to be larger than the diameter of the metering tube main body 11 (preferably twice it), so that, from the upper bridge tube 30 The soap film bubbles with increased thickness enter the straight pipe main body 21 and burst due to the rapid increase in surface area. After the soap film bubbles burst, the foam-making agent will fall in the pipe or flow down into the foam-making agent along the pipe wall.

[0045] The soap film flowmeter provided by this application enables the double bubbles or multi-bubbles formed during the operation to be destroyed and recovered by the gas to the other side, and the unbroken bubbles also slowly fall and move to the foaming agent on the other side Liquid level, so as to eliminate the influence of redundant air bubbles on the next measurement cycle; let the bubble breaking proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com