Heat pump unit utilizing waste heat of oily sewage through double evaporators

A technology of double evaporator and heat pump units, which is applied in the direction of evaporator/condenser, refrigerator, compressor, etc., can solve the problems of low calorific value, strong corrosion, etc., increase waste heat recovery, save energy consumption, improve The effect of heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings:

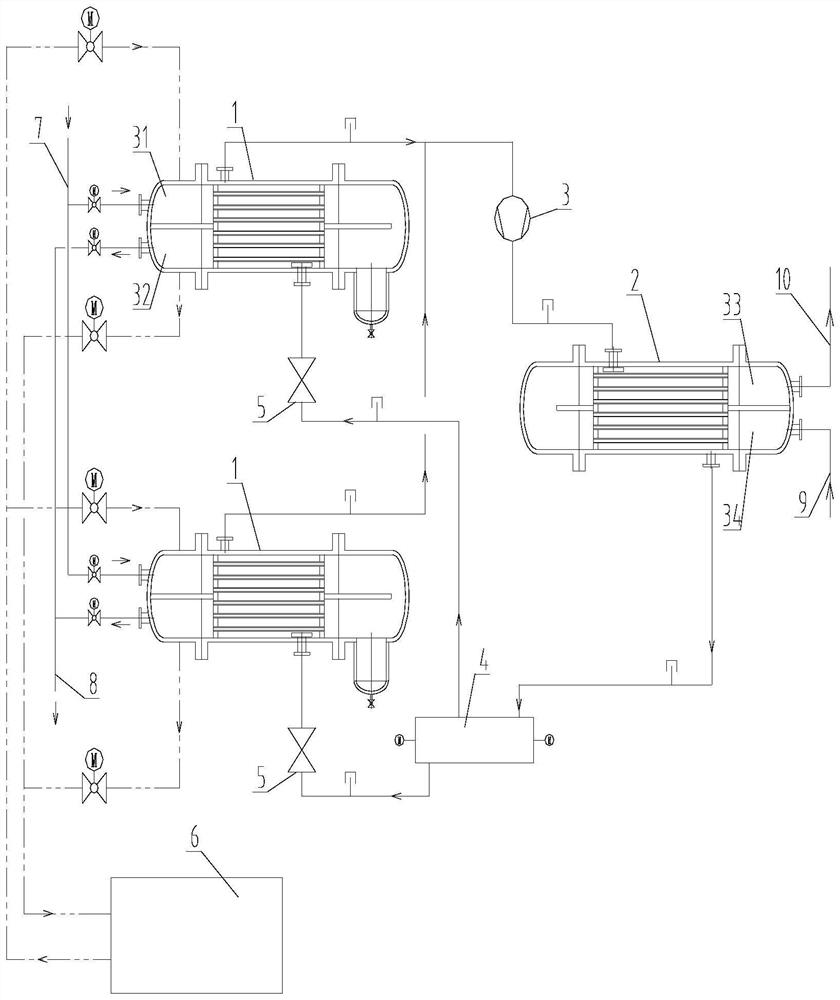

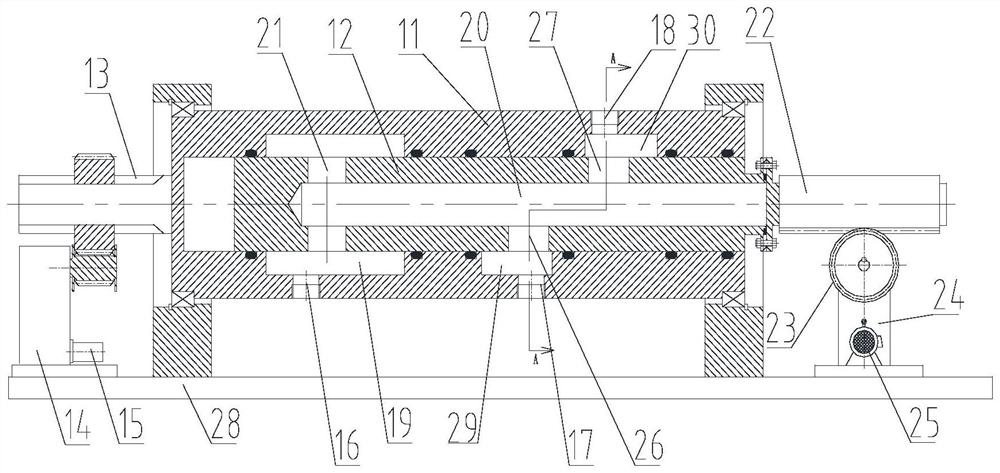

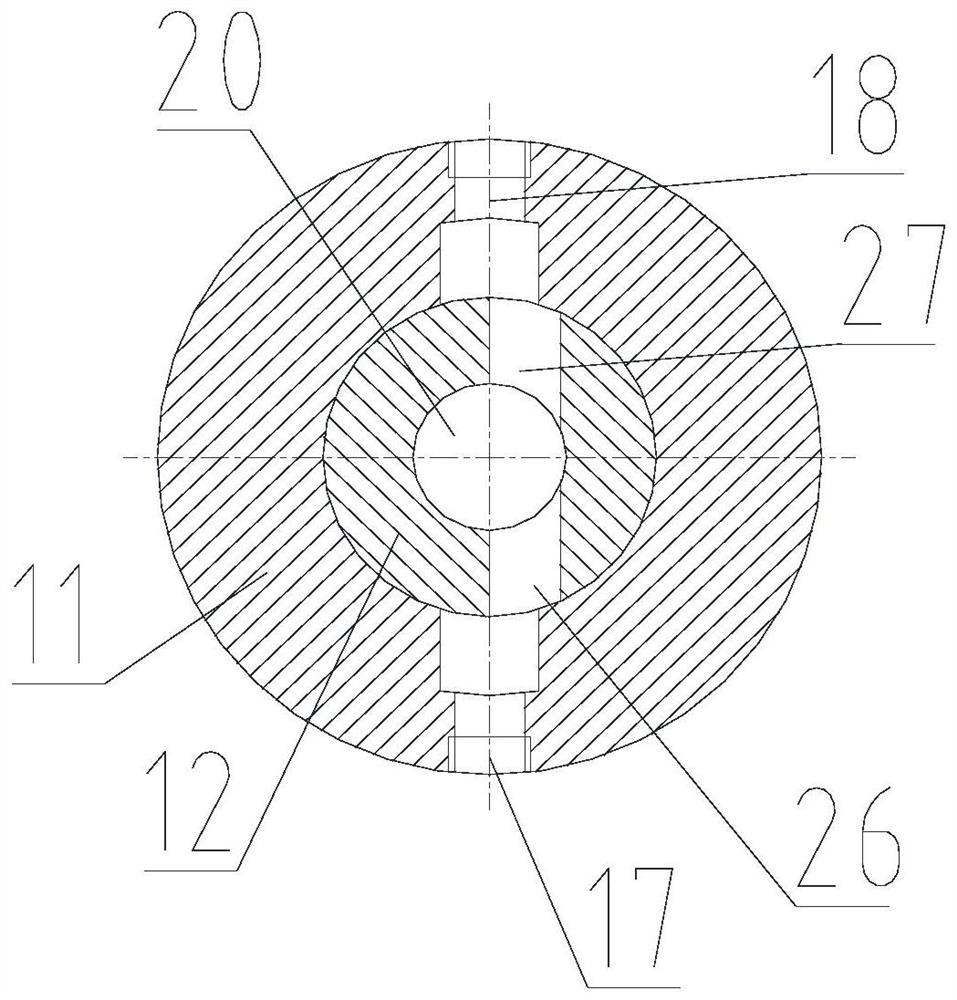

[0019] Depend on figure 1 combine Figures 2 to 4 As shown, a dual-evaporator heat pump unit using oily sewage waste heat includes a condenser 2, the inlet refrigerant pipe of the condenser 2 is connected to the outlet of the compressor 3, the inlet of the compressor 3 is connected in parallel with the outlet refrigerant pipes of the two evaporators 1, and the two The refrigerant inlet pipes of each evaporator 1 are respectively provided with expansion valves 5, the inlet pipes of the two expansion valves 5 are respectively connected to the outlet of the refrigerant distribution valve 4, the inlet of the refrigerant distribution valve 4 is connected to the outlet refrigerant pipe of the condenser 2, each evaporation valve The water inlet chamber A31 of the evaporator 1 is connected to the heat source inlet pipe 7, the water outlet chamber A32 of each evaporator 1 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com