Flat gate valve with excellent sealing performance under low-pressure condition

A flat gate valve, low-pressure technology, applied in valve details, valve devices, sliding valves, etc., can solve the problems of entering the valve, poor sealing, low pressure, etc., to improve sealing, ensure abutment, and reduce gnawing phenomenon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

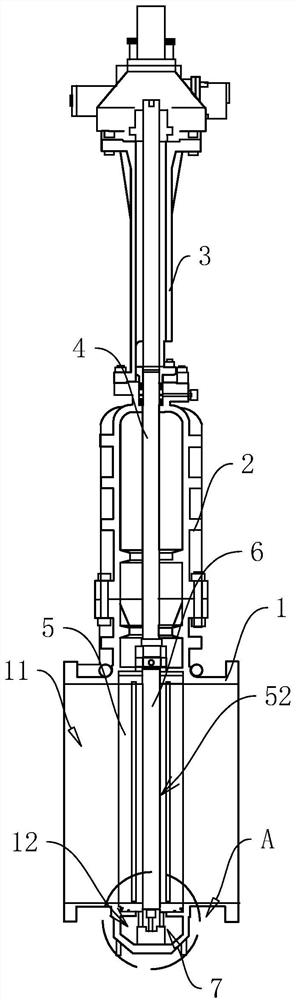

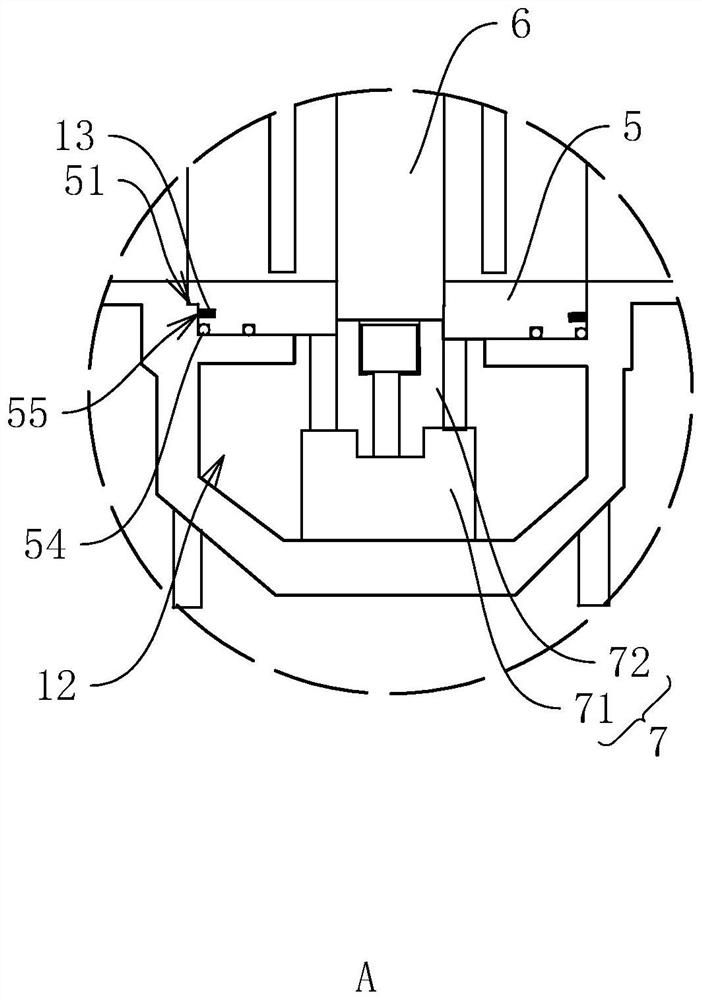

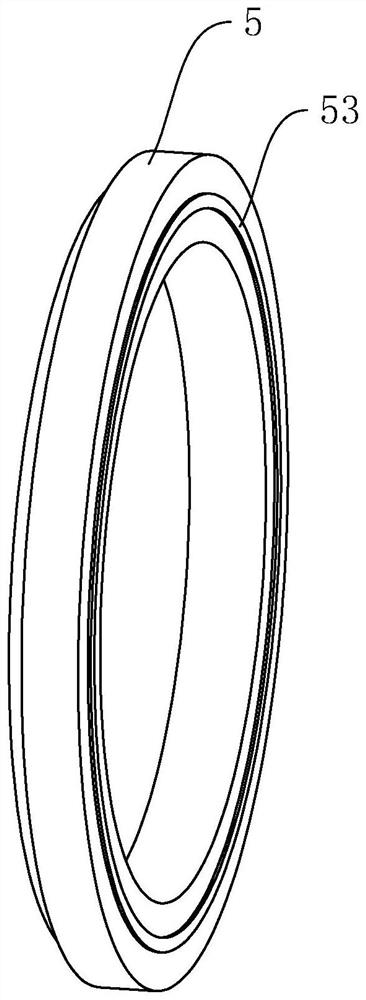

[0039] refer to figure 1 and figure 2, A flat gate valve with excellent sealing performance under low pressure conditions includes a valve body 1, a valve cover 2, a bracket 3, a valve stem 4, a floating valve seat 5 and a gate plate 6. The valve body 1 is provided with a flow chamber 11, and the valve cover 2 is connected to the upper side of the valve body 1 by bolts, the bracket 3 is fixed above the valve cover 2 by bolts, the valve stem 4 is lifted up and down in the bracket 3 and the valve cover 2, there are two floating valve seats 5, and the two float The edge of the valve seat 5 is provided with a trapezoidal groove 51 , and the two floating valve seats 5 abut in the flow chamber 11 of the valve body 1 through the trapezoidal groove 51 , and a lifting gap 52 is formed between the two floating valve seats 5 . The gate 6 is lifted and lowered within the lifting gap 52 , and the bottom of the valve stem 4 is fixedly connected with the upper side of the gate 6 .

[0040...

Embodiment 2

[0051] refer to Image 6 and Figure 7 The difference between this embodiment and Embodiment 1 is that the limit block 72 and the lower cushion block 71 are not fixedly connected by bolts, the lower cushion block is fixedly connected with a plug-in rod 711, and the limit block 72 is provided with a plug-in rod 71. The connecting rod 711 is inserted into the slot 721 for sliding fit, and the upper end of the connecting rod 711 is integrally formed with a limit piece 7111 , and the limit piece 7111 abuts against the top notch of the insertion slot 721 of the limit block 72 for preventing The limit block 72 is disengaged from the lower cushion block. The limit block 72 is located in the insertion slot 721 to form a contact surface 73 . The insertion rod 711 is sleeved with a buffer spring 9 , and one end of the buffer spring 9 is fixedly connected to the lower cushion block. , and the other end is fixedly connected to the contact surface 73 .

[0052] When the shutter 6 is clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com