Intelligent flow calibration gear pump

A gear pump and flow rate technology, which is applied in pump control, machine/engine, mechanical equipment, etc., can solve the problems of gear end face wear, gear pump outlet flow reduction, and gear end face clearance increase, etc., to improve service life and outlet flow Stable, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

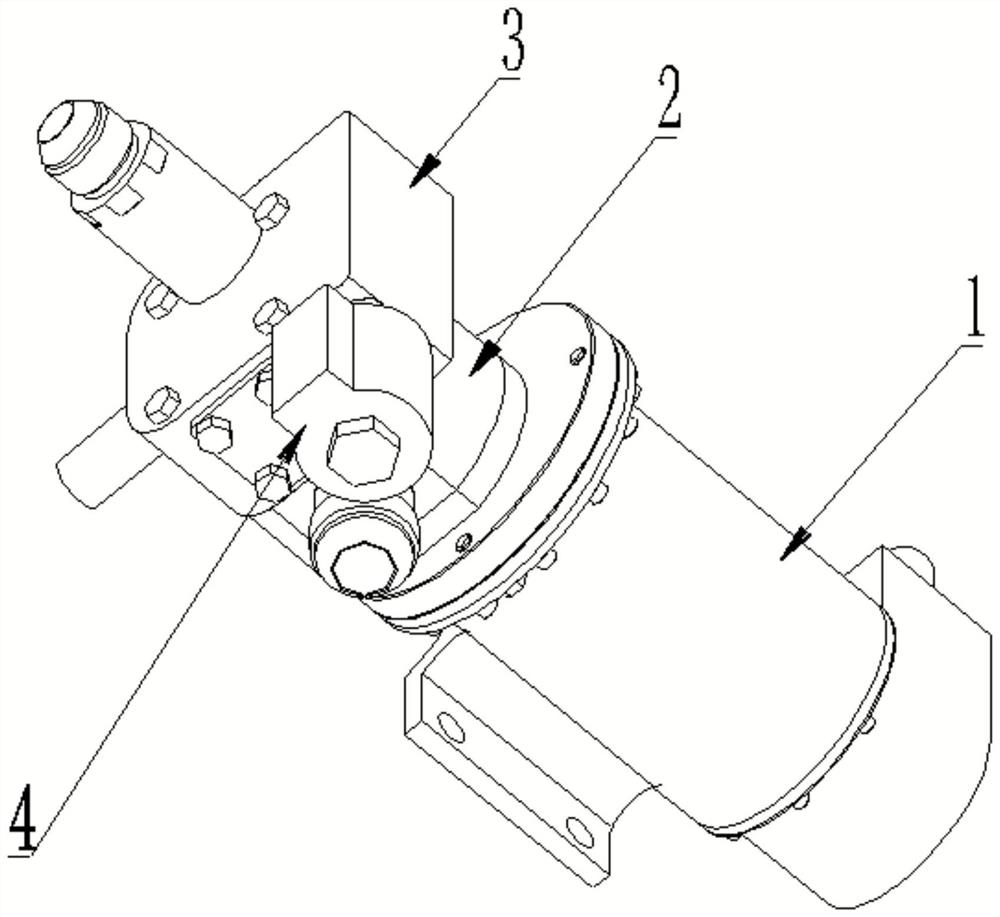

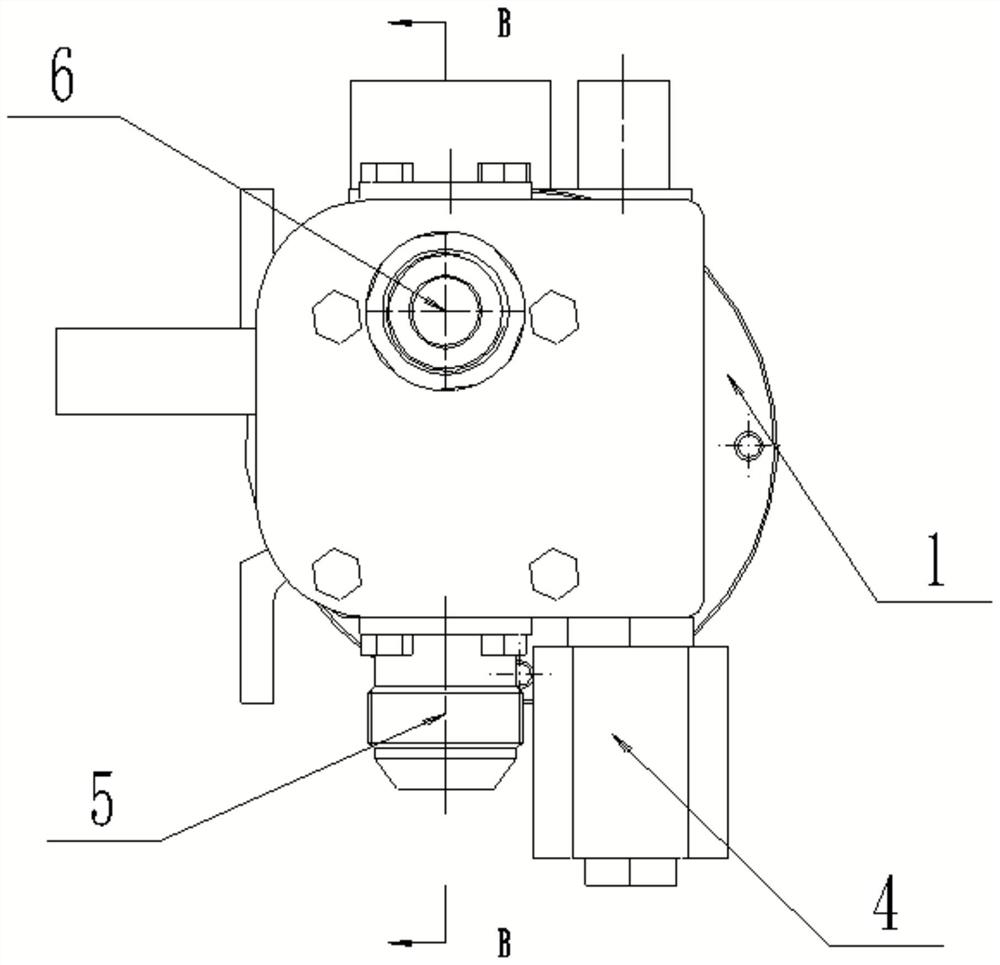

[0033] like Figure 1-11 Show, a traffic intelligent calibration gear pump, including the gear pump pump body, the gear pump body is opened with main oil port 5, main outlet outlet 6, motor component on the gear pump body 1. Gear pump component 2. Control valve component 3; the control valve component includes the control valve shell installed on the gear pump. The control valve shell is installed in the main valve to change the flow of the liquid in the gear pump. , The first oil outlet, a throttle drool, the first oil outlet, and the throttling droosure as the oil end of the two positions of the main valve, respectively. The oil outlet is connected with the main oil port; the control valve shell is also installed in the pilot valve 4 used to control the main valve core. The valve core 11 is connected to the driver source 18, and the pressure sensor is connected to the drive source 18 by the controller. Among them, the main valve and the pilot valve are both four -bodium four -way...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com