Cement sheath eccentric rolling extrusion crushing tool for long-service-life auxiliary sleeve recovery

A technology of extrusion and crushing and cement sheath, which is applied in wellbore/well components, earth-moving drilling, etc., can solve the problem of increasing the abandonment operation cycle and cost, unfavorable smooth casing recovery operation, and increasing casing pulling resistance, etc. problems, to achieve the effect of easy procurement, maintenance and replacement, shortening the recycling operation cycle, and reducing the resistance of the casing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

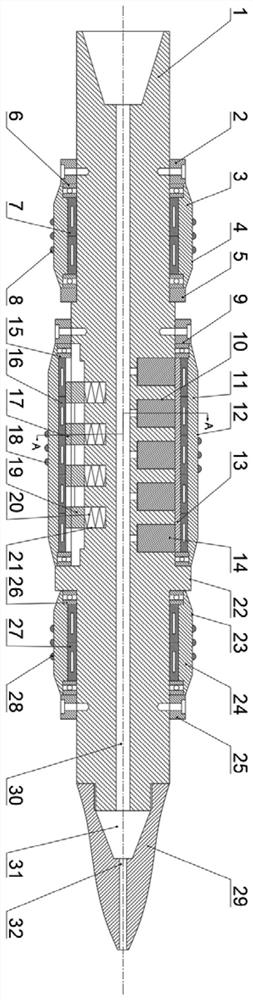

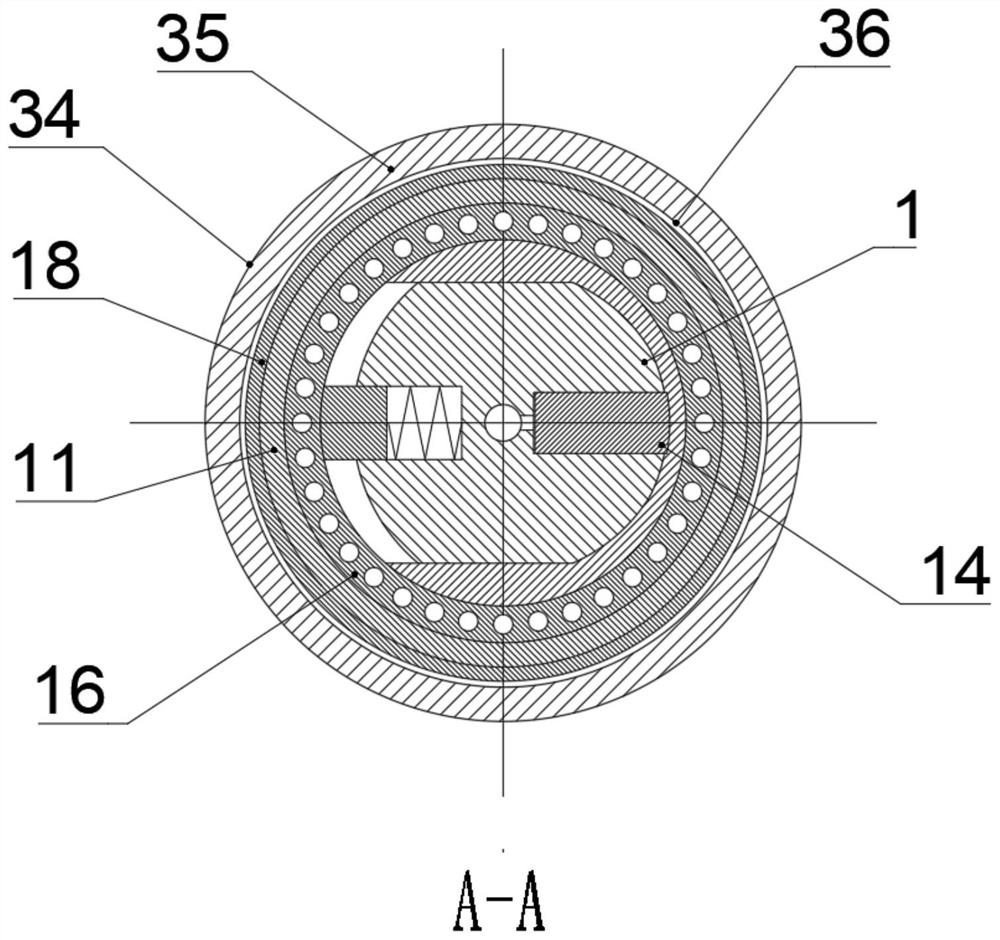

[0032] A cement ring eccentric rolling extrusion crushing tool for auxiliary casing recovery with high life, such as Figure 1 to Figure 6 As shown, it includes main shaft 1, upper roller 4, movable roller 12, lower roller 23, moment ferrule 13, thrust bearing A2, thrust bearing B15, thrust bearing C26, radial bearing A7, radial bearing B16, radial bearing C27 , the piston 14, the centralizer 17, the lower joint 29, the movable roller 12 is installed on the main shaft 1 through the thrust bearing B15, the radial bearing B16 and the moment ferrule 13 and under the action of the centralizer 17, and the movable roller 12 is located on the upper roller 4 Between the main shaft 1 and the lower roller 23, the upper roller 4 and the lower roller 23 are installed through the thrust bearing and the radial bearing, the lower joint 29 is installed on the bottom of the main shaft 1 using a threaded connection, and a cylindrical water nozzle 32 is opened inside the lower joint 29. , by adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com