Tail gas emission and recovery system of gasoline sweetening production device

A production device and tail gas emission technology, which is applied in the fields of liquid hydrocarbon mixture recovery, petroleum industry, and multi-stage series refining process treatment, etc., can solve problems such as pollution, non-compliant production, loss of gasoline environment, etc., to prevent excessive pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

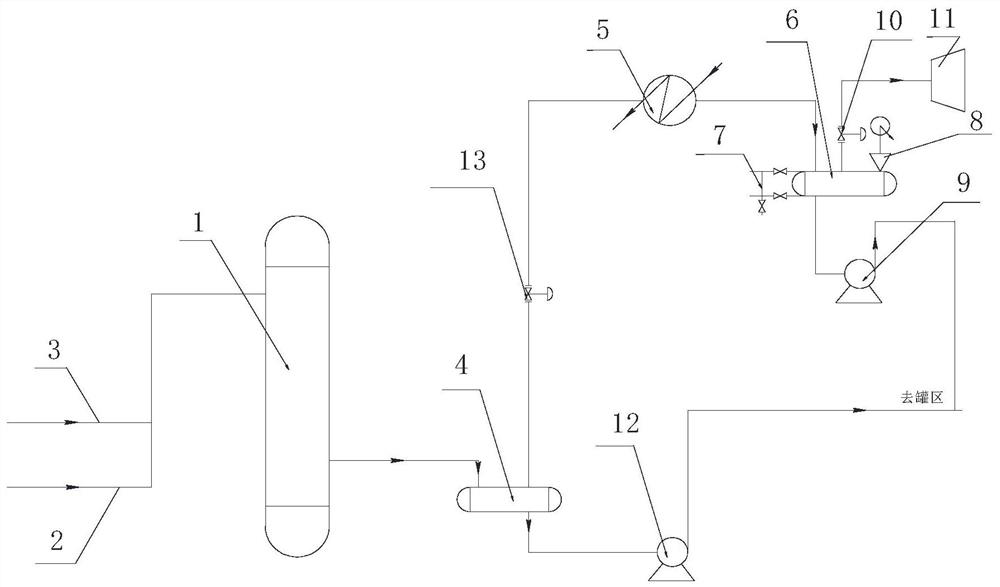

[0028] The present invention will be further described below in conjunction with the accompanying drawings:

[0029] as attached figure 1 As shown, the tail gas emission recovery system of this gasoline desulfurization production unit comprises gasoline desulfurization reactor 1, and the top feed line of described gasoline desulfurization reactor 1 connects gasoline pipeline 2 and non-purified air pipeline 3; gasoline desulfurization reactor 1 1. The bottom outlet pipeline is connected to the oil and gas separation tank 4.

[0030] The 4 tank bottom pipelines of the oil and gas separation tank are connected to the refined gasoline pump 12, and the refined gasoline is drawn out and sent to the tank farm through the refined gasoline pump 12; Condensed into a liquid phase for recovery; a control valve 13 is connected to the top pipeline of the oil and gas separation tank 4.

[0031] The rear tank of the cooler 5 is connected to a buffer tank 6, which is used to contain the gaso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com