Anti-yellowing low-mold-scale halogen-free flame-retardant polyamide composite material and preparation method thereof

A technology of flame retardant polyamide and composite material, which is applied in the field of anti-yellowing, low mold scale, halogen-free flame retardant polyamide composite material and its preparation, and can solve the problem of affecting product appearance performance, high injection speed, and burning of plastic parts at the end. and other problems, to achieve excellent anti-yellowing and low mold scale characteristics, good mechanical properties, and high flame retardant properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

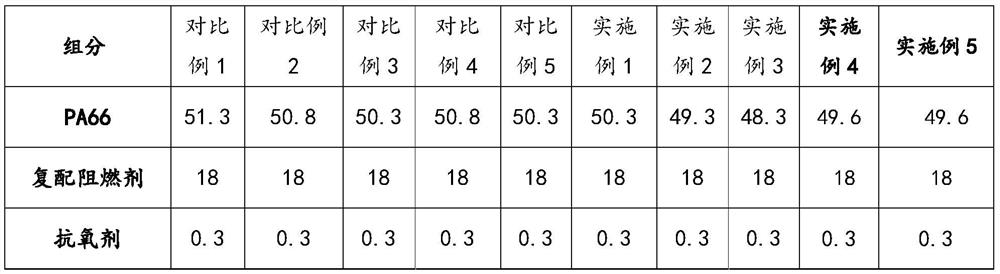

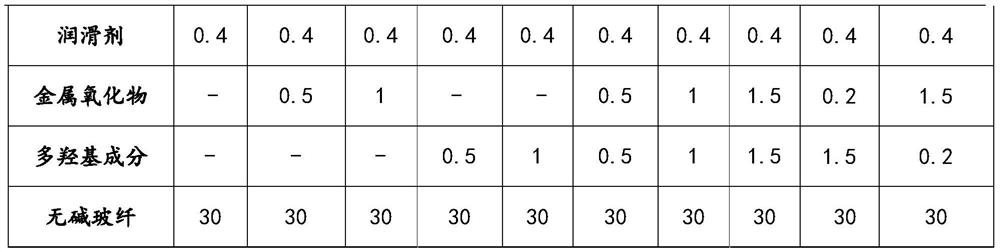

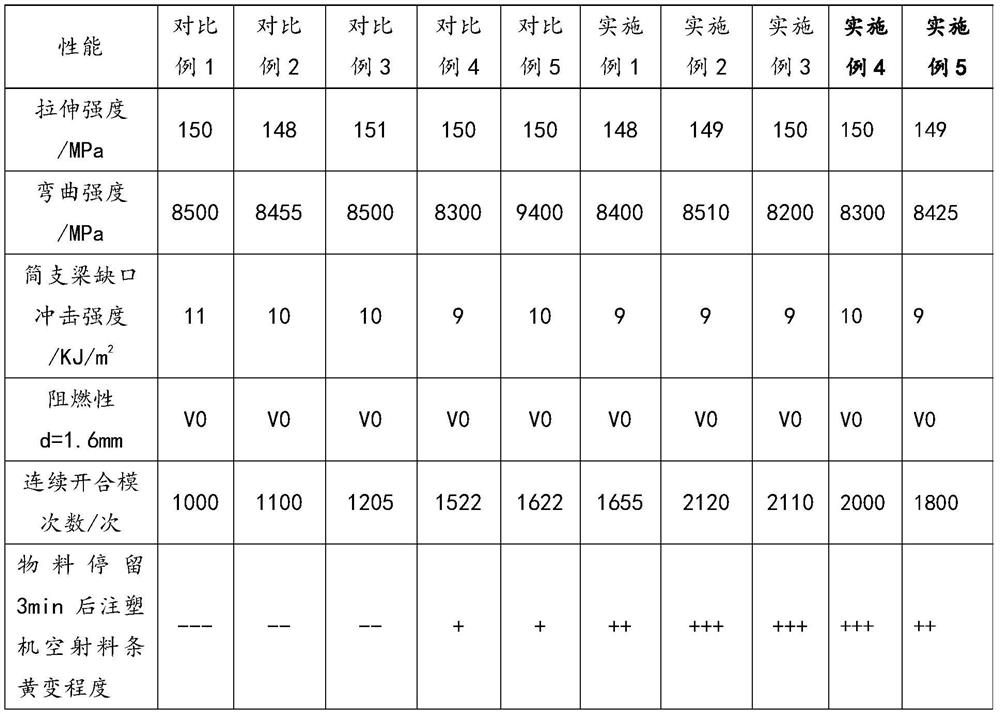

Examples

preparation example Construction

[0027] The present invention also provides a method for preparing a halogen-free flame retardant polyamide composite material with anti-yellowing and low mold scale, which comprises the following steps:

[0028] (1) Weigh metal oxides, polyhydroxy components, lubricants, antioxidants by a certain weight and carry out powdering treatment to obtain a uniformly mixed mixture M; wherein, the raw material components after powdering treatment can be mixed more fully, Give full play to the function of trace additives.

[0029] (2) Add half of the polyamide resin and mixture M into the high-speed mixer together, mix at high speed for a certain period of time, and finally mix the remaining half of the polyamide resin in the high-speed mixer for a certain period of time, and finally obtain a uniform mixture The mixture N; wherein, the mixing is more uniform and sufficient by step-by-step mixing.

[0030] (3) The obtained mixture N is fed into the twin-screw extruder through the main fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com