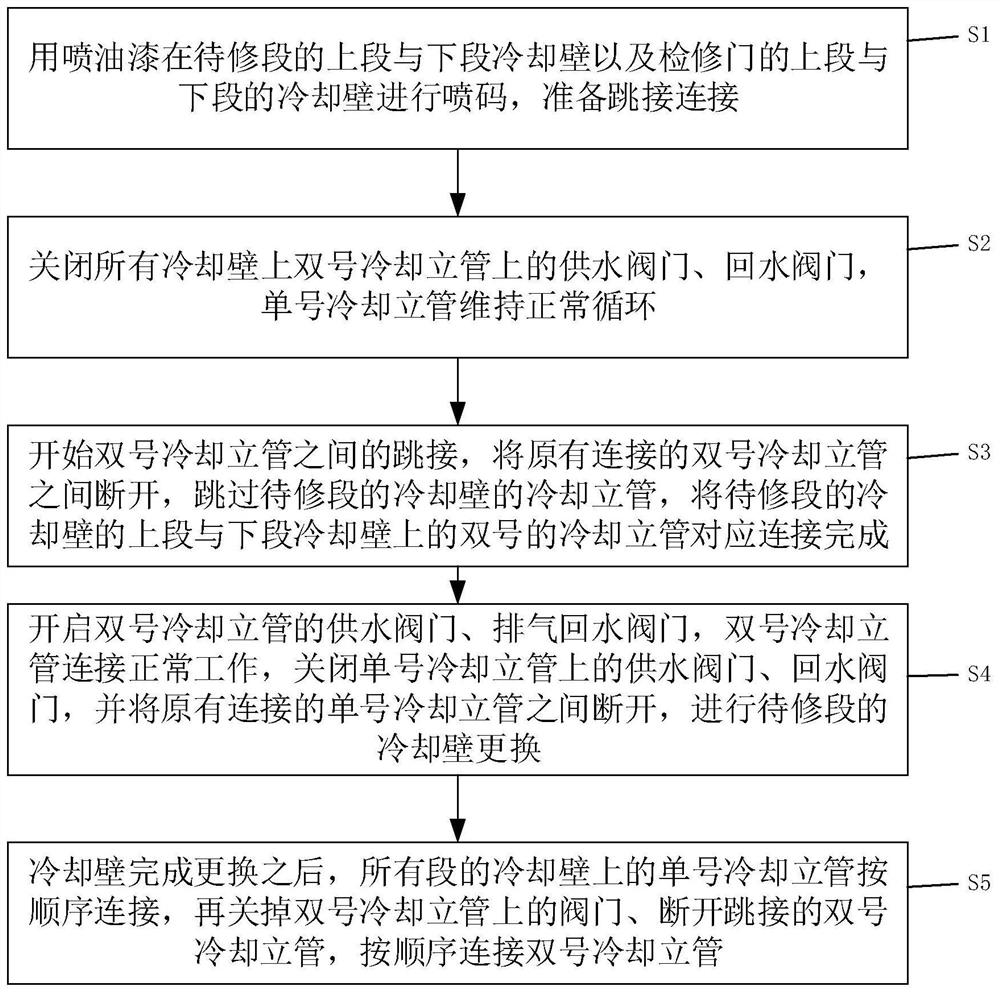

Method for jumper connection of cooling stand pipe in medium repair of blast furnace

A riser and jumper technology, which is applied in the field of steelmaking plants, can solve the problems of heavy and tight time, achieve the effect of prolonging the service life, solving the problem of leak detection defects and potential safety hazards, and ensuring stable and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

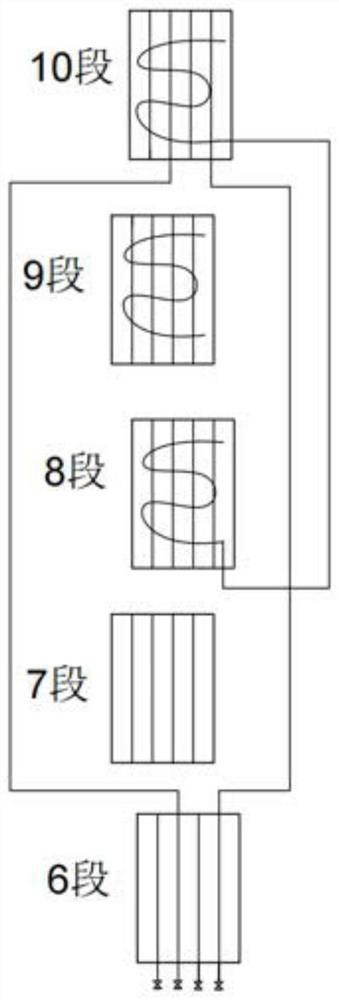

[0064] Before shutting down the furnace, use spray paint to spray the number plates of 46 cooling staves in 6 sections and 40 cooling staves in 10 sections with numbers, so as to facilitate the jumping of pipes and the successful installation of cooling U-shaped connecting hoses. The leather pipe is hoisted to the 10-stage platform with a crane.

[0065] There are 46 cooling risers in East C area, and 23 double-numbered jumpers. Specific operations:

[0066] In the 14th section of the furnace top, turn off all double-number return water valves and open the exhaust valve;

[0067] The soft water closed-circuit circulation system of the single-number temporary connection remains normal, and the jumper connection is completed.

[0068] In the first stage of the furnace base, turn off all double-number water supply valves and open the sewage to drain the water.

[0069] The single-number temporary water closed-circuit circulation system remains normal, and the jumping is complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com