Building waste recovery device for building construction

A technology for construction waste and construction, applied in the field of construction waste recycling devices for construction, can solve problems such as poor recycling effect, inability to recycle waste in a targeted manner, environmental pollution, etc., to improve recycling efficiency, save maintenance costs, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

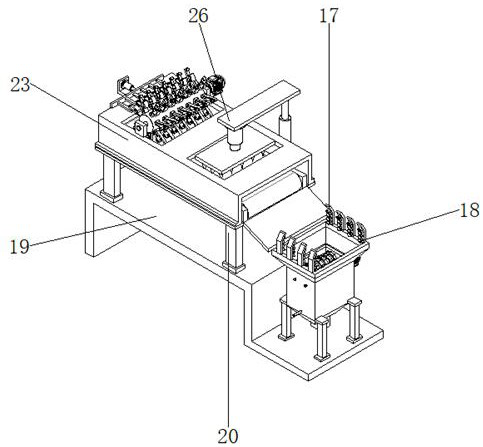

[0034] refer to Figure 1-5 , a construction waste recycling device for construction, comprising a crushing box 1, the bottom four corners of the crushing box 1 are welded with support legs 2, and the top outer wall of the crushing box 1 is installed with a feeding hopper 3, and the interior of the crushing box 1 is installed along the length direction. The crushing rollers 4 are symmetrically distributed, and the outer wall of one end of the crushing rollers 4 is connected with a first servo motor 5 through a coupling. The arc-shaped clamping block 7 is slidably clamped, and the outer wall of the arc-shaped clamping block 7 is welded with annular crushing teeth 8;

[0035] A fixing ring 9 is welded on the outer wall of one side of the ring-shaped crushing teeth 8, and the ring-shaped crushing teeth 8 on the two crushing rollers 4 are displaced from each other. A rotating shaft 13 is connected, the top outer wall of the rotating shaft 13 is installed with a cleaning scraper 1...

Embodiment 2

[0044] refer to Figure 2-7 , a construction waste recycling device for construction, comprising a crushing box 1, the bottom four corners of the crushing box 1 are welded with support legs 2, and the top outer wall of the crushing box 1 is installed with a feeding hopper 3, and the interior of the crushing box 1 is installed along the length direction. The crushing rollers 4 are symmetrically distributed, and the outer wall of one end of the crushing rollers 4 is connected with a first servo motor 5 through a coupling. The arc-shaped clamping block 7 is slidably clamped, and the outer wall of the arc-shaped clamping block 7 is welded with annular crushing teeth 8;

[0045] A fixing ring 9 is welded on the outer wall of one side of the ring-shaped crushing teeth 8, and the ring-shaped crushing teeth 8 on the two crushing rollers 4 are displaced from each other. A rotating shaft 13 is connected, the top outer wall of the rotating shaft 13 is installed with a cleaning scraper 1...

Embodiment 3

[0055] refer to Figure 5-9 , a construction waste recycling device for construction, comprising a crushing box 1, the bottom four corners of the crushing box 1 are welded with support legs 2, and the top outer wall of the crushing box 1 is installed with a feeding hopper 3, and the interior of the crushing box 1 is installed along the length direction. The crushing rollers 4 are symmetrically distributed, and the outer wall of one end of the crushing rollers 4 is connected with a first servo motor 5 through a coupling. The arc-shaped clamping block 7 is slidably clamped, and the outer wall of the arc-shaped clamping block 7 is welded with annular crushing teeth 8;

[0056] A fixing ring 9 is welded on the outer wall of one side of the ring-shaped crushing teeth 8, and the ring-shaped crushing teeth 8 on the two crushing rollers 4 are displaced from each other. A rotating shaft 13 is connected, the top outer wall of the rotating shaft 13 is installed with a cleaning scraper 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com