3D-printed high-conductivity healing-promoting multichannel nerve conduit and preparation method and application thereof

A nerve conduit and 3D printing technology, which is applied in medical science, prosthesis, additive processing, etc., can solve the problems of little research, achieve reduced adverse reactions, high biological safety, and eliminate long-term inflammation-related side effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, the preparation of PLA-PTMC catheter

[0032] (1) Weigh N,N-dimethylformamide and dichloromethane in a mass ratio of 7:3, and mix them evenly.

[0033] (2) Weigh the PLA-PTMC copolymer particles, and dissolve them in the mixed solution obtained in step (1) according to a mass ratio of 45:100 to obtain a PLA-PTMC mixed gel solution;

[0034] (3) Fill the PLA-PTMC gel obtained in step (2) into the 3D printer barrel, and the 3D printer prints, and the 3D printing content is one 3mm*12mm flat plate and four 8mm*12mm flat plates, each of which is 8mm*12mm. The content of the flatbed printing is that the two layers of mechanical layers and the guiding long axis are at 45° and perpendicular to each other, the fiber spacing in the layers is 1.0mm, and the inner spacing of one guiding layer is 0.3mm.

[0035] (4) After printing, the sample prepared in step (3) is placed in a refrigerator for pre-freezing for half an hour for shaping, and then freeze-dried for 4-6 ...

Embodiment 2

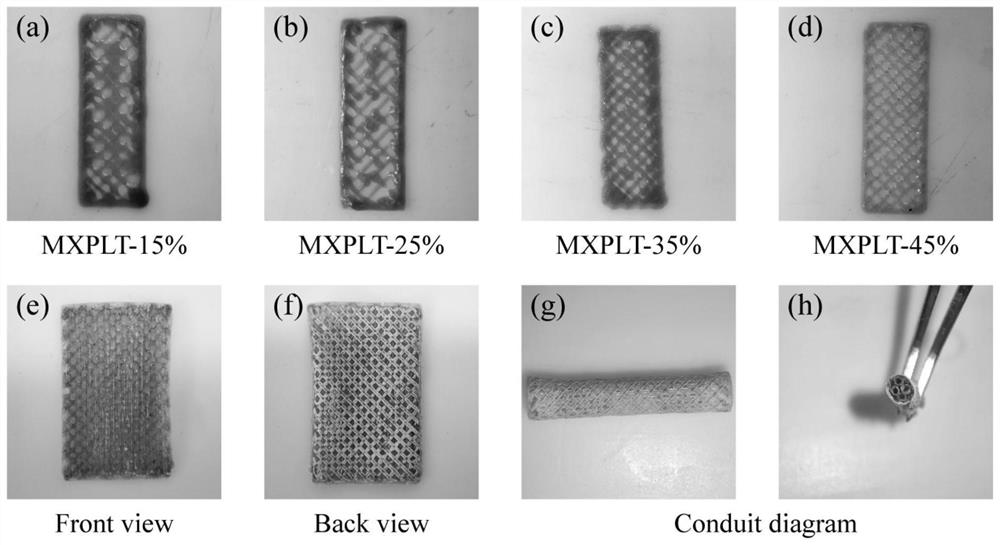

[0038] Example 2. Preparation of MXPLT-15% catheter

[0039] (1) Weigh N,N-dimethylformamide and dichloromethane according to the mass ratio of 7:3, and mix them evenly;

[0040] (2) Weigh Ti 3 C 2 T x The powder is dissolved in the mixed solution obtained in step (1) according to a mass ratio of 2:1000 to obtain a mixed solution of MXene;

[0041] (3) Weigh the PLA-PTMC copolymer particles, and dissolve them in the mixed solution obtained in step (2) according to a mass ratio of 15:100 to obtain a MXPLT mixed gel solution;

[0042] (4) Filling the MXPLT mixed gel solution obtained in step (3) into the 3D printer barrel, and the 3D printer prints, the 3D printing content is one 3mm*12mm flat plate and four 8mm*12mm flat plates, each The content of the flatbed printing is that the two mechanical layers and the guiding long axis are at 45° and perpendicular to each other, the fiber spacing in the layers is 1.0mm, and the inner spacing of one guiding layer is 0.3mm;

[0043]...

Embodiment 3

[0046] Example 3. Preparation of MXPLT-25% catheter

[0047] The preparation method of this embodiment is the same as that of embodiment 2, except that the mass ratio of PLA-PTMC to mixed solvent in step (3) is 25:100, to obtain a mixed gel solution of MXPLT. Prepared nerve conduits such as figure 1 (b).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com