Codable ultrasonic tweezers system and implementation method thereof

An implementation method, ultrasonic technology, applied in the direction of sounding devices, instruments, etc., can solve the problems of large number of transducers, difficulty in independent control, inability to change the focus position of ultrasonic waves, and the directional movement of particles, so as to achieve the effect of simplifying the signal generation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

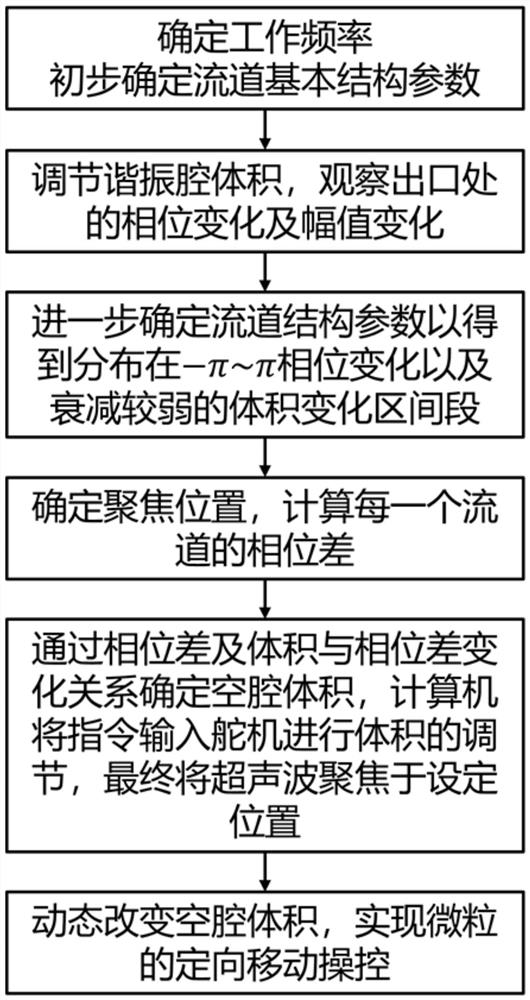

[0069] see figure 1 , a method for implementing a coded ultrasonic tweezers of the present invention, comprising the following steps:

[0070] S1. Determine the operating frequency to be 20-60 kHz, and preliminarily determine the parameters of the flow channel unit, including the number of flow channels, area, wall thickness, slit area, number of resonant cavities, volume of resonant cavity and other parameters;

[0071] The size parameters of the flow channel unit vary with the determination of the frequency. The overall value is λ / 30~λ / 6, the number of resonant cavities is 4~7, and the number of flow channels is 16~30. Materials with high acoustic impedance, such as stainless steel, are preferred.

[0072] S2. Use commercial finite element simulation software to simulate the ultrasonic time-domain signal at the outlet of the flow channel with the change of the cavity volume, and calculate the amplitude and phase changes of the time-domain signal;

[0073] The finite element...

Embodiment

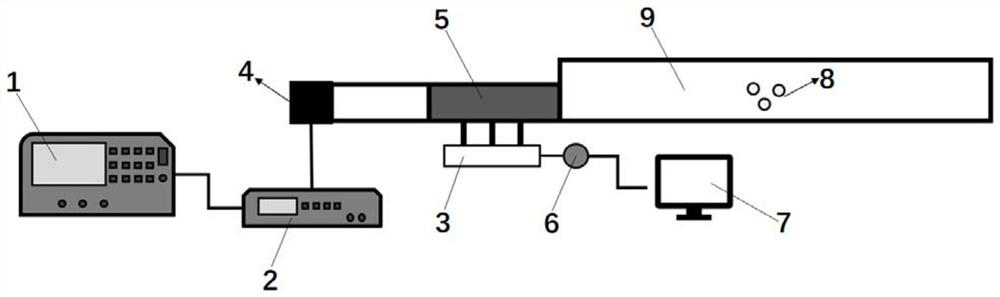

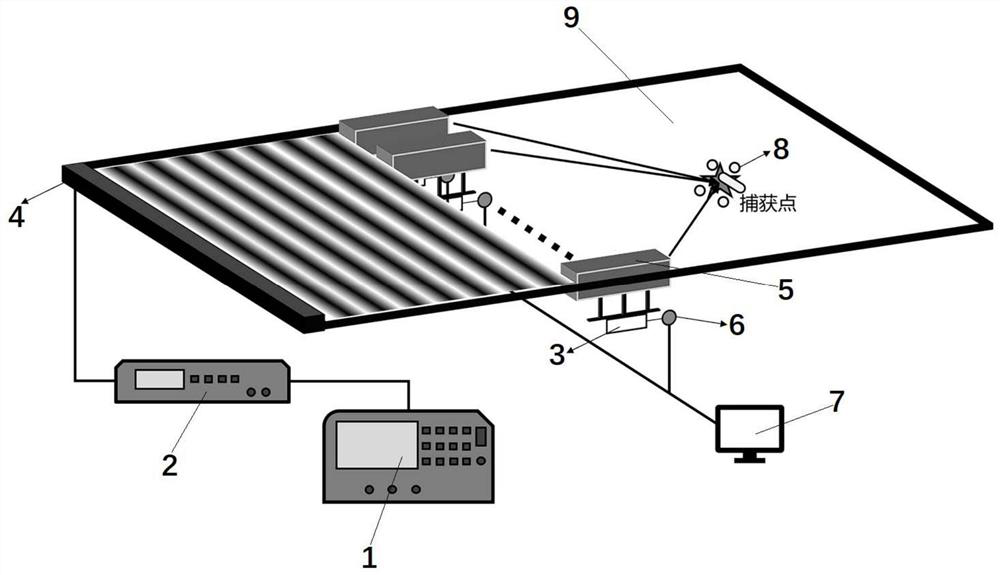

[0083] Design an acoustic tweezers system with 5 resonant cavities and 24 flow channels. The ultrasonic operating frequency is determined to be 50kHz. The three-dimensional schematic diagram and plan view of the flow channel structure are as follows Figure 4 and Figure 5 As shown, the number of resonant cavities is determined to be 5, and the size information is h1=1mm, h2=5mm, h3=1mm, h4=0.5mm, L1=1mm, L2=3mm, L3=0.3mm, w1=5mm, w2 =4mm.

[0084] hx is variable to adjust the cavity volume, which varies from 0 to 5 mm.

[0085] w1 is the thickness of the flow channel unit, and w2 is the thickness of the inner cavity of the flow channel unit.

[0086] The number of flow channels is determined to be 24, and the material is stainless steel. Since the cross-section of the resonant cavity is determined, the volume change will be represented by the height of the resonant cavity.

[0087] The variation of the amplitude and phase with the height of the resonator is obtained by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com