Torque testing system for electric actuator

An electric actuator and torque testing technology, which is applied in the testing of machines/structural components, electromagnetic measuring devices, and testing of mechanical components, can solve problems such as leakage and unqualified transmission components, and improve measurement accuracy and failure Analyzing the Effects on Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0039] In the description of the present invention, it should be understood that the terms "center", "longitudinal", "lateral", "length", "width", "thickness", "upper", "lower", "front", " Rear, Left, Right, Vertical, Horizontal, Top, Bottom, Inner, Outer, Clockwise, Counterclockwise, Axial, The orientations or positional relationships indicated by "radial direction", "circumferential direction", etc. are based on the orientations or positional relationships shown in the accompanying drawings, which are only for the convenience of describing the present invention and simplifying the description, rather than indicating or implying the indicated devices or elements. It must have a specific orientation, be constructed and operate in a specific orientation, and therefore should not be construed as a limitation of the present invention.

[0040] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be furthe...

Embodiment 1

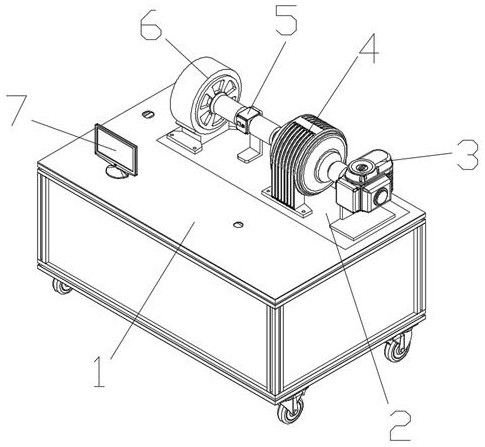

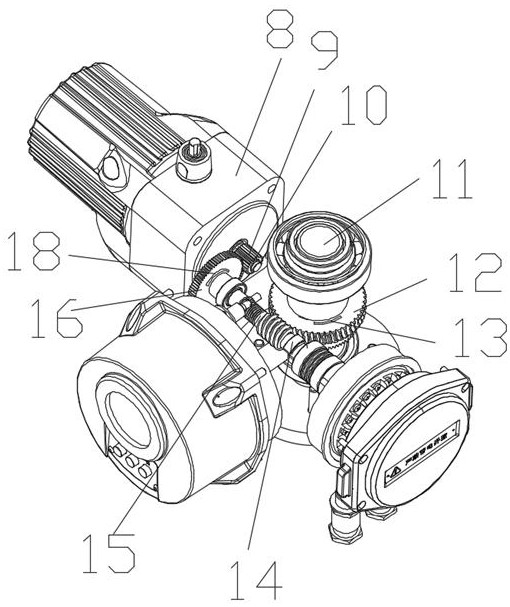

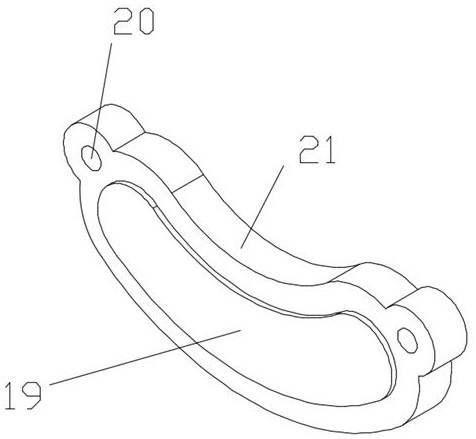

[0043] like figure 1 As shown, an electric actuator torque testing system includes a workbench 1, a control center is arranged in the workbench 1, a fixing device 2 is arranged on the workbench 1, and the fixing device 2 is provided with a plurality of fixing seats for fixing different Model of electric actuator 3, when the electric actuator 3 is fixed on the fixing device 2, the output shaft of the electric actuator 3 is connected with the reducer 4 through a coupling, and the reducer 4 is connected with one end of the dynamic torque sensor 4 through the coupling Connection, the other end of the dynamic torque sensor 4 is connected with the load loader that provides the torque load, the load loader is connected as a magnetic powder brake, the dynamic torque sensor 4 is connected with the control center of the test system, and the fixture 2 is also provided with a number of wireless connections with the control center. connected piezoelectric surface acoustic wave sensors 21, ...

Embodiment 2

[0069] On the basis of Embodiment 1, from the multiple measurement results of the second measurement value by the control center, according to the result of the density function f(x), a measurement value with a probability range less than 0.1 is selected as the comparison data and the prediction of the control center database. Set the second specified value comparison, the density function f(x) formula:

[0070]

[0071] u is the geometric mean of these n second measurements and δ is the standard deviation.

[0072] Select the second measurement values according to the above method, indicating that the occurrence of these measurement values does not conform to the qualified quality law, and is the detection result of possible failure, and compare these second measurement values with the preset second specified value of the control center database. By comparison, find out the components that are less than or equal to the corresponding second specified value, as the tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com