Test bed for multi-stage servo valve

A servo valve and test bench technology, applied in mechanical valve testing, fluid pressure actuating system testing, fluid pressure actuating system components, etc. Detect problems such as multi-stage servo valve pilot stage spool valve, and achieve the effect of complete test parameters, high accuracy and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

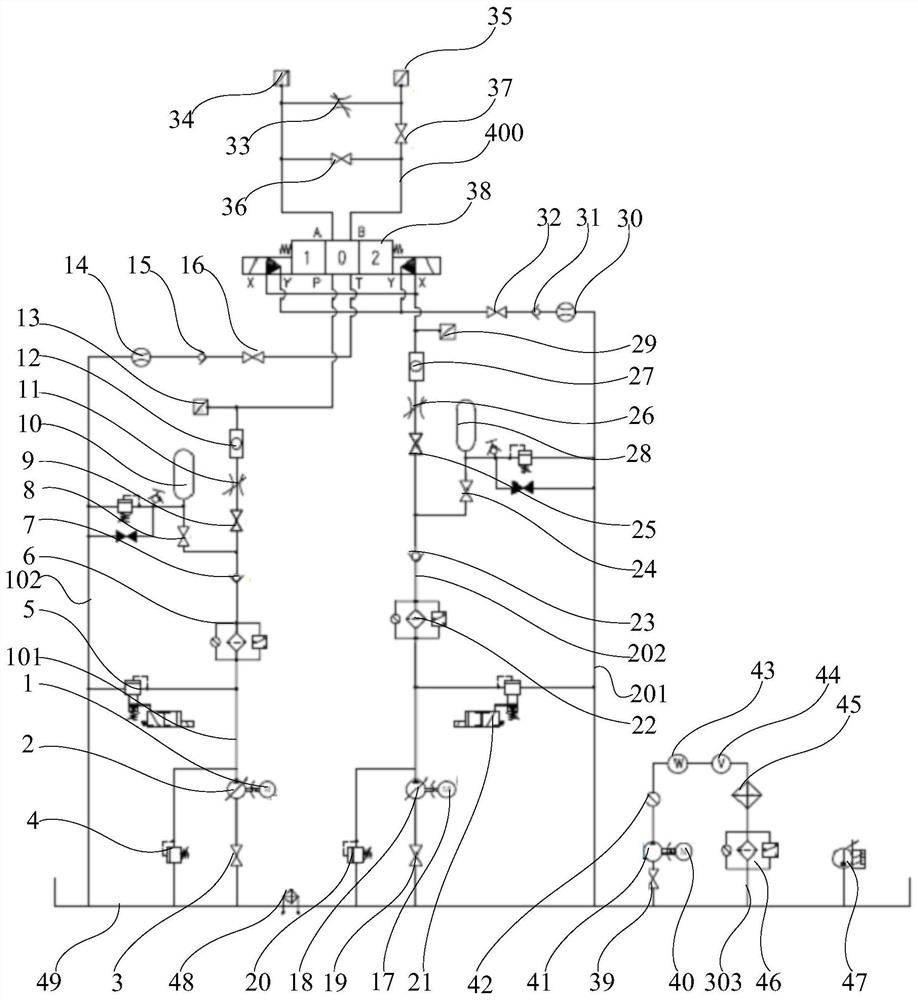

[0070] In order to better understand the above technical solutions, the technical solutions of the embodiments of the present application will be described in detail below with reference to the accompanying drawings and specific embodiments. The detailed description is not intended to limit the technical solutions of the present application, and the embodiments of the present application and the technical features in the embodiments may be combined with each other without conflict.

[0071] The embodiment of the present application proposes a test bench for a multi-stage servo valve, including: a workbench for setting the servo valve 38 to be tested; a test oil pressure oil supply device, which is set on the workbench and is used for testing the servo valve 38 to be tested 38 supplies test oil; pilot oil supply device, set on the workbench, is used to supply pilot oil to the servo valve 38 to be tested; oil tank 49, the test oil pressure oil supply device and the pilot oil supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com